Preparation method of bioglass fiber reinforced hydroxyapatite porous composite material

A porous composite material, hydroxyapatite technology, applied in the field of biomedical material preparation, can solve the problems of reducing the stability of the implant-bone interface and not having biological activity, and achieve excellent biocompatibility and bioactivity , Good penetrating pore structure, high specific strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

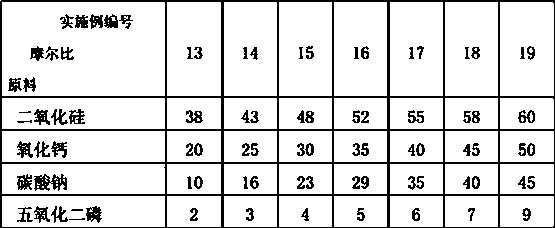

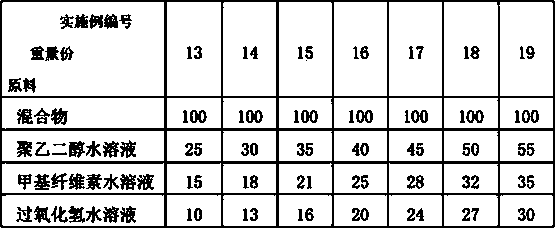

Embodiment 1

[0029] Weigh according to the molar ratio of silica: calcium oxide: sodium carbonate: phosphorus pentoxide is 45:45:8:2, mix evenly and add to platinum crucible, heat up to 1100°C at a heating rate of 2.5°C / min. The raw materials are subjected to high-temperature treatment for 2 hours, and the high-temperature-treated raw materials are quickly poured into deionized water for water quenching, and the bioglass formed by water quenching is filtered out, and dried at 50°C for 12 hours, and the bioglass can be prepared for use ; Put the prepared bioglass into a platinum crucible with a leak, heat up to 1200°C at a heating rate of 2.5°C / min to melt the bioglass for 2 hours, draw the molten bioglass at the leak of the platinum crucible On the rotating wire winding drum, the drawing process is carried out according to the drawing speed of 500m / min, and the biological glass fiber with a diameter of 5 microns can be obtained on the wire winding drum; the molar concentration is 0.3mol / 1...

Embodiment 2

[0031] Weigh according to the molar ratio of silica: calcium oxide: sodium carbonate: phosphorus pentoxide is 50:35:10:5, mix evenly and add to platinum crucible, heat up to 1200°C at a heating rate of 5°C / min. The raw materials are subjected to high-temperature treatment for 3 hours, and the high-temperature-treated raw materials are quickly poured into deionized water for water quenching, and the bioglass formed by water quenching is filtered out, and dried at 55°C for 16 hours, and the bioglass can be prepared for use ; Put the prepared bioglass into a platinum crucible with a leak, heat up to 1300°C at a heating rate of 5°C / min to melt the bioglass for 3 hours, and guide the molten bioglass at the leak of the platinum crucible On the rotating winding drum, the drawing process is carried out according to the drawing speed of 450m / min, and the biological glass fiber with a diameter of 8 microns can be obtained on the winding drum; according to the molar ratio of calcium to ph...

Embodiment 3

[0033] Weigh according to the molar ratio of silicon dioxide: calcium oxide: sodium carbonate: phosphorus pentoxide of 50:40:9:1, mix evenly and add to platinum crucible, heat up to 1250°C at a heating rate of 8°C / min. The raw materials are subjected to high-temperature treatment for 4 hours, and the high-temperature-treated raw materials are quickly poured into deionized water for water quenching, and the bioglass formed by water quenching is filtered out, and dried at 60°C for 12 hours, and the bioglass can be prepared for use Put the prepared bioglass into a platinum crucible with a leak, heat up to 1300°C at a heating rate of 8°C / min to melt the bioglass for 2 hours, draw the molten bioglass at the leak of the platinum crucible On the rotating winding drum, the wire drawing process is carried out according to the drawing speed of 400m / min, and the biological glass fiber with a diameter of 10 microns can be obtained on the spinning drum; the molar concentration of calcium an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com