Method for manufacturing static stretching thin film reflecting mirror

A thin-film mirror and electrostatic technology, which is applied in installation, optics, instruments, etc., can solve the problems of insufficient surface shape accuracy of electrostatic stretched film mirrors, and achieve the effect of simple electrode distribution structure, convenient operation, and improved surface shape accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

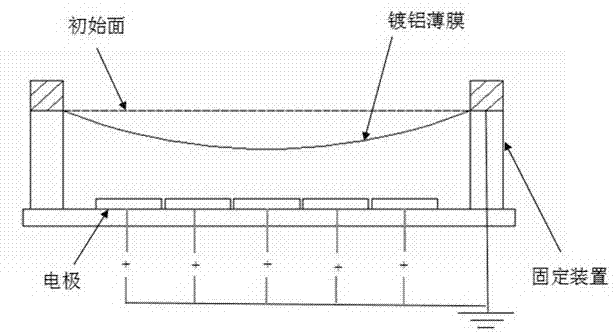

[0018] See attached figure 1 , which is a schematic diagram of the principle structure for preparing an electrostatically stretched film mirror; fix the periphery of the film in the film mirror to be formed on the ring fixing device to obtain the initial surface, place the electrodes directly below the film, and input voltage to each electrode Signal. Since the periphery of the film in the film mirror is fixed on the ring device, when the planar film is subjected to a high pressure load, each point on the film will be displaced relative to the initial planar film position, and the film has almost no lateral stiffness and cannot bear bending moment The large deformation equation of the circular film obtained by simplification of the Karman equation circular film theory is shown in the following formulas (1) and (2):

[0019]

[0020] in is the elastic modulus of the film, is the film thickness, is the stress function, is the disturbance value, is the film radius (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com