Method and device for manufacturing light trap with hollow photonic crystal fiber

A hollow photonic crystal and optical fiber technology, which is applied in the fields of optical inertial navigation and optical engineering, can solve the problems of increasing the difficulty of alignment accuracy and capturing, affecting the effect of optical trapping force, and large laser energy loss, so as to improve energy utilization and reduce energy consumption. Influence and improve the effect of alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

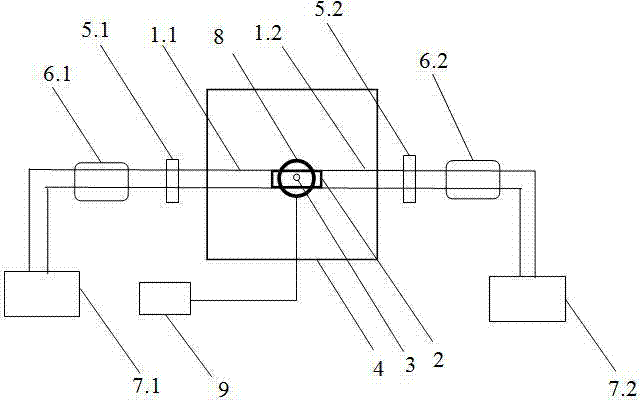

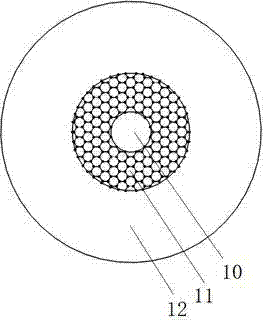

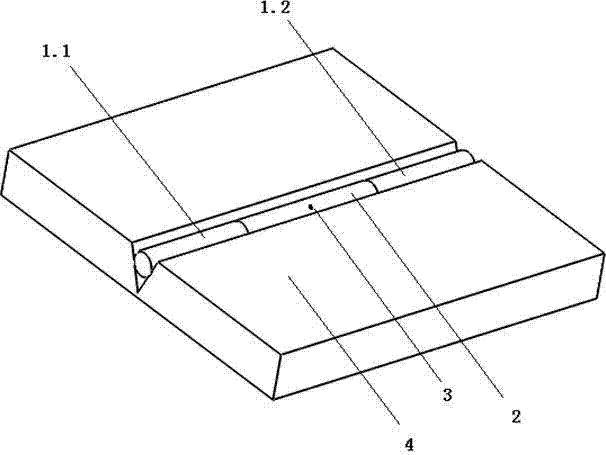

[0027] The specific steps of a device for preparing an optical trap using a hollow photonic crystal fiber are:

[0028] 1. Make the glass substrate 4, place the spherical particles 3 in the hollow core of the hollow photonic crystal fiber 2, fuse and connect the outgoing end faces of the two single-mode optical fibers 1 to the hollow photonic crystal fiber 2, and fix the three optical fibers by transparent ultraviolet glue In the V-shaped groove of the glass substrate 4, the schematic diagram of the glass substrate made after this step is completed is shown in the attached image 3 ;

[0029]Two, place the glass substrate 4 horizontally under the photoelectric image detector 8, open the photoelectric image detector 8, computer 9 and video acquisition software, place the microscopic objective lens of the photoelectric image detector 8 at the minimum magnification, and roughly Adjust the position of the glass substrate 4 to make the image of the hollow photonic crystal fiber 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com