Method for degrading humic pollutants by catalytic wet cooxidation

A technology of co-oxidation and humic substances, which is applied in the field of treatment of humic pollutants, can solve problems such as high reaction temperature, and achieve the effects of high reaction activity, low treatment cost and thorough removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 catalytic wet co-oxidation process fulvic acid aqueous solution

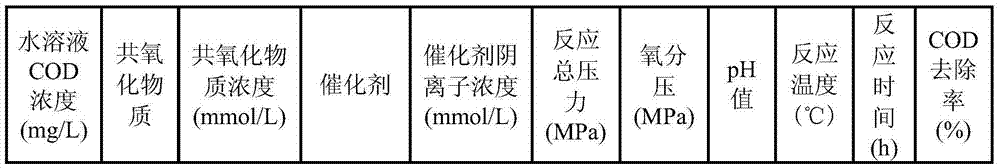

[0024] A method for degrading humic pollutants by catalytic wet co-oxidation of the present invention, specifically catalytic wet co-oxidation method for treating fulvic acid aqueous solution, comprising the following steps: making 20mL pH value 2-12, COD concentration 100-400mg / L The aqueous solution of fulvic acid is added to the autoclave, and then one or more of methanol, ethanol, propanol, isopropanol, phenol, aniline, and chlorophenol are added to the aqueous solution as a co-oxidation substance to make the co-oxidation substance The ratio of the molar concentration to the COD concentration of the fulvic acid aqueous solution is 0.01 to 10mmol / L: 100mg / L, and the catalyst is added at the same time so that the ratio of the anion molar concentration of the catalyst to the COD concentration of the fulvic acid aqueous solution is 0.01 to 10mmol / L: 100mg / L L, sealed, and finally filled with ...

Embodiment 2

[0028] Embodiment 2 catalytic wet co-oxidation process humic acid aqueous solution

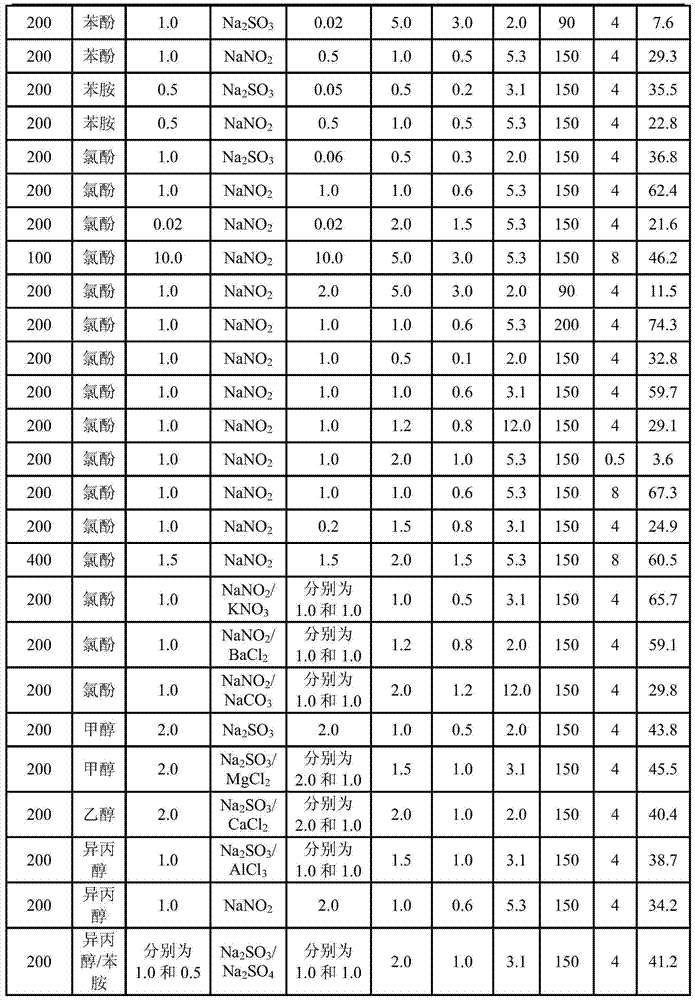

[0029] A method for degrading humic pollutants by catalytic wet co-oxidation of the present invention is specifically a catalytic wet co-oxidation method for treating humic acid aqueous solution (i.e. humic acid wastewater), comprising the following steps: making 20mL COD concentration 100mg / L, BOD 5 / Humic acid wastewater with a COD value of 0.05 (pH=7.0) was added to the autoclave, and then chlorophenol was added as a co-oxidation substance, and NaNO was added at the same time 2 As a catalyst, seal it, and finally fill it with 0.5MPa oxygen, stir it magnetically at a speed of 500rpm, and react at 150°C for 4 to 6 hours. The COD removal rate of the solution after the reaction (when calculating the COD removal rate, the initial COD concentration includes COD concentration of acid wastewater and COD concentration of co-oxidized substances) and BOD 5 / COD values are shown in Table 2 (“–” me...

Embodiment 3

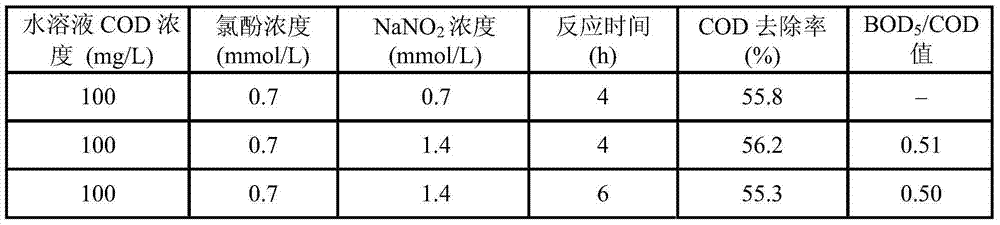

[0032] Example 3 Catalytic wet co-oxidation method to treat late landfill leachate

[0033] A method for degrading humus pollutants by catalytic wet co-oxidation of the present invention, specifically catalytic wet co-oxidation method for treating late-stage landfill leachate, containing humus pollutants in the landfill leachate, comprising the following steps: / L, BOD 5 Late landfill leachate with a COD value of 0.08 was added to the high-pressure reactor, and then chlorophenol was added as a co-oxidation substance, and NaNO was added at the same time 2 As a catalyst, seal it, and finally fill it with 0.5MPa oxygen, stir it magnetically at a speed of 500rpm, and react at 150°C for 4 to 6 hours. The COD removal rate of the solution after the reaction (when calculating the COD removal rate, the initial COD COD concentration of filtrate and COD concentration of co-oxidized substances) and BOD 5 / COD values are shown in Table 3 (“–” means not detected).

[0034] Table 3 COD ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com