A microreactor device and its application in the preparation of sulfonated products of benzene series

A micro-reactor and product technology, which is applied in chemical/physical/physical-chemical reactors, sulfonic acid preparation, chemical/physical/physical-chemical processes, etc., can solve the problems of many by-products and high reaction temperature, and improve the conversion rate , Enhance mass transfer and heat transfer, reduce the effect of requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

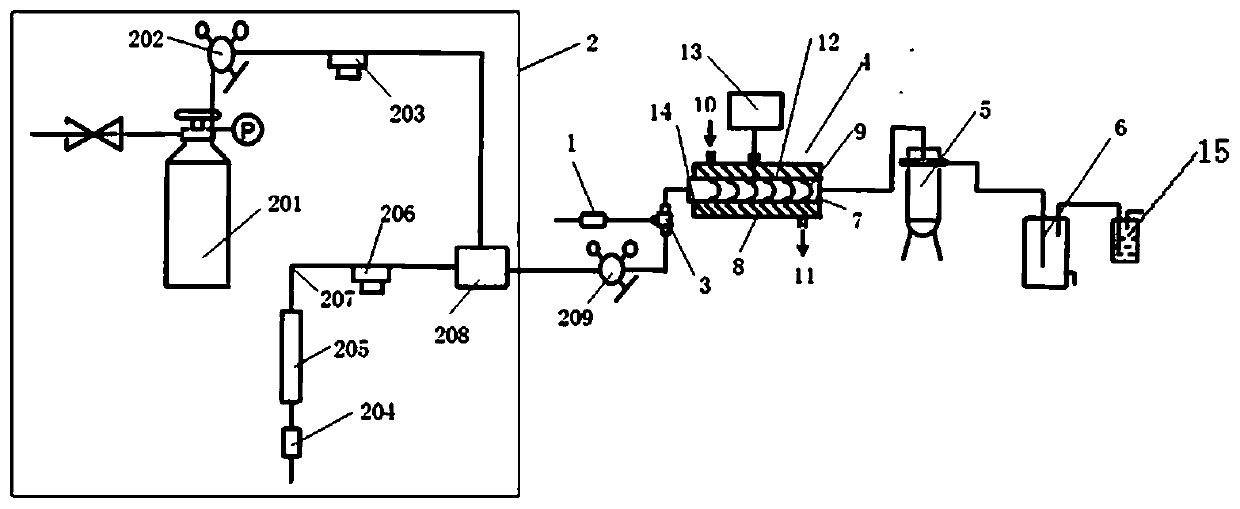

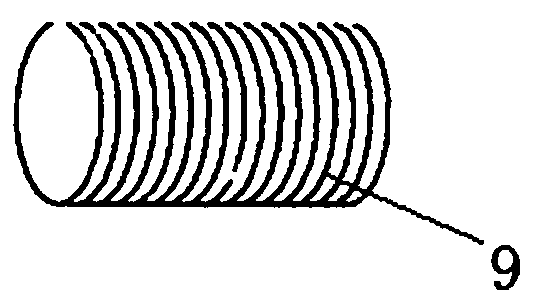

[0032] See figure 1 , a micro-reaction device, comprising a liquid feed pump 1, a gas feed device 2, a mixer 3, a microreactor 4, a back pressure valve 5 and a product collection tank 6, a liquid feed pump 1, a gas feed device 2 Link to each other with mixer 3 respectively, outlet of mixer 3, microreactor 4, back pressure valve 5, product collection tank 6 and lye tank 15 are connected in series, microreactor 4 comprises reaction cavity 7 and heat exchange jacket 8, reaction A reaction tube 9 is arranged inside the chamber 7, and a heat exchange jacket 8 is arranged outside the reaction chamber 7. The upper part of the heat exchange jacket 8 is provided with a condensed water inlet 10, and the lower part of the heat exchange jacket 8 is provided with an exchanged condensed water outlet 11. . A sealing layer 12 is provided on the outer wall of the reaction chamber 7 for isolating the reaction chamber 7 and the heat exchange jacket 8 from each other.

[0033] The microreactor ...

Embodiment 2

[0041] Microchannel reaction device is the same as embodiment 1, microchannel reaction tube inner diameter 6mm, the total volume 1000ml of microchannel reaction tube, SO in the mixed gas 3 The concentration dilution is 6%, the feeding amount of benzene is 300ml, SO 3 The molar ratio to benzene is 1:1.7, the reaction residence time is 10min, the reaction temperature is 10°C, and the pressure of the back pressure valve is 1MPa; the conversion rate of benzene is 57.5%, and the selectivity of benzenesulfonic acid is 88.2%.

Embodiment 3

[0043] Microchannel reaction device is the same as embodiment 1, microchannel reaction tube inner diameter 7mm, the total volume 1000ml of microchannel reaction tube, SO in the mixed gas 3 The concentration dilution is 6%, the feeding amount of benzene is 300ml, SO 3 The molar ratio to benzene is 1:1.7, the reaction residence time is 10min, the reaction temperature is 10°C, and the pressure of the back pressure valve is 1MPa; the conversion rate of benzene is 55.6%, and the selectivity of benzenesulfonic acid is 84.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com