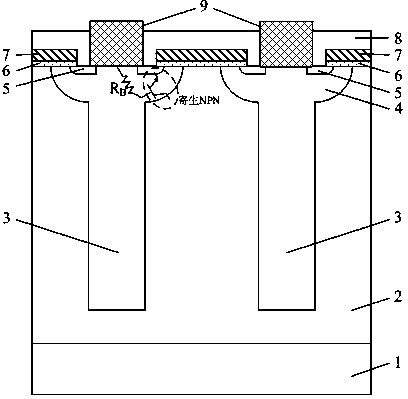

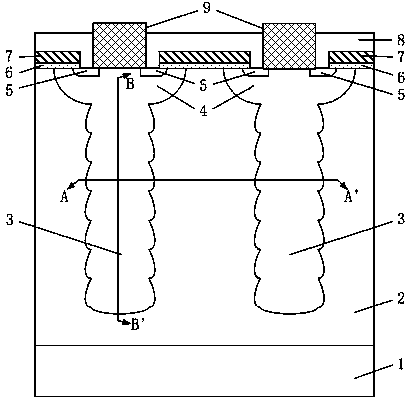

Super junction semiconductor device manufacturing method capable of improving avalanche capacity

A superjunction semiconductor and device technology, which is applied in the field of preparation of superjunction semiconductor devices, can solve the problems of reduced breakdown voltage, aggravated lateral diffusion, and increased on-resistance, so as to reduce lateral diffusion and reduce doping concentration gradient. , the effect of increasing the effective width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] This embodiment is described using a MOSFET having a superjunction structure, but the present invention is not limited to MOSFETs.

[0056] 1. Substrate material preparation, using N with a resistivity of 0.001Ω??cm + Zone-melted single crystal silicon substrate 1, the crystal orientation of which is ;

[0057] Second, in N + A 5 μm N-type epitaxial layer with a resistivity of 4Ω??cm is epitaxially grown on the substrate as a P column and N + buffer layer between substrates;

[0058] 3. Epitaxial growth of a 5 μm N-type epitaxial layer with a resistivity of 4Ω??cm on the surface of the silicon wafer;

[0059] 4. Deposit 6 μm negative photoresist on the surface of the silicon wafer (i.e., perform boron ion implantation where there is a P-pillar pattern), use a P-pillar mask to expose and develop, and then perform four high-energy boron ion implantations. The energy of boron ions is 3.5MeV, 2.5MeV, 1.2KeV and 200KeV in sequence, and the dose of boron ions implanted is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com