Anti-sunshine waterproof polyester resin and production process thereof

A polyester resin and production process technology, applied in the field of additives for preparing coatings, can solve problems such as a single synthesis method, and achieve the effects of improving UV resistance, increasing water resistance and anti-fouling, and facilitating painting operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

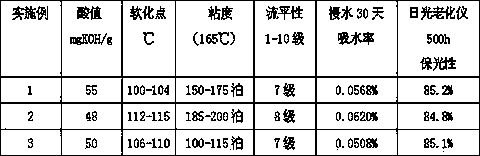

Examples

Embodiment 1

[0019] Example 1: The concrete preparation method of the production of a kind of anti-sunlight and water-resistant polyester resin of the present invention is as follows: Esterification: add the purified terephthalic acid and neopentyl glycol that molar mass ratio is 1.08:1 in the reaction kettle successively , the fly reactor uses heat-conducting oil as a carrier, the reaction is gradually heated up, and the temperature reaches 200°C, and the mixture is stirred for 6 hours;

[0020] Polycondensation: After the esterification reaction is completed, lower the reaction temperature, cool to room temperature, let it stand for 10 minutes, and proceed to the heating reaction. When the temperature is lower than 50°C, add a small amount of hypophosphorous acid as an antioxidant for polyester synthesis. The addition amount is 0.1% of the total mass of raw materials, and the mass ratio is 15% of the total reaction mass ratio of isophthalic acid is added under the condition of 150 °C in ...

Embodiment 2

[0030] Example 2: The concrete preparation method of the production of a kind of anti-sunlight and water-resistant polyester resin of the present invention is as follows: Esterification: add the purified terephthalic acid and neopentyl glycol that molar mass ratio is 1.15:1 in the reaction kettle successively , the fly reactor uses heat-conducting oil as a carrier, the reaction is gradually heated up, and the temperature reaches 200°C, and the mixture is stirred for 8 hours;

[0031] Polycondensation: After the esterification reaction is completed, lower the reaction temperature, cool to room temperature, let it stand for 10 minutes, and proceed to the heating reaction. When the temperature is lower than 50°C, add a small amount of hypophosphorous acid as an antioxidant for polyester synthesis. The amount of addition is 0.3% of the total mass of raw materials. Under the condition that the temperature in the reactor is 150°C, isophthalic acid with a mass ratio of 20% of the to...

Embodiment 3

[0041] Example 3:The concrete preparation method of the production of a kind of anti-sunlight and water-resistant polyester resin of the present invention is as follows: Esterification: adding the purified terephthalic acid and neopentyl glycol that the molar mass ratio is 1.12:1 in the reaction kettle successively , the fly reactor uses heat-conducting oil as a carrier, and the reaction is gradually heated up, and mixed and stirred for 7 hours when the temperature reaches 200 ° C;

[0042] Polycondensation: After the esterification reaction is completed, lower the reaction temperature, cool to room temperature, let it stand for 10 minutes, and proceed to the heating reaction. When the temperature is lower than 50°C, add a small amount of hypophosphorous acid as an antioxidant for polyester synthesis. The amount of addition is 0.2% of the total mass of raw materials. Under the condition that the temperature in the reactor is 150°C, isophthalic acid with a mass ratio of 18% of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com