High-power press-fitted IGBT packaging module

A packaging module, crimping technology, applied in electrical components, electric solid devices, circuits, etc., can solve the problems of limiting the power range of devices, selecting new structural materials without breakthrough changes, restricting the development of devices, etc., to achieve anti-oxidation performance. Excellent, good electrical insulation, easy to make and assemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

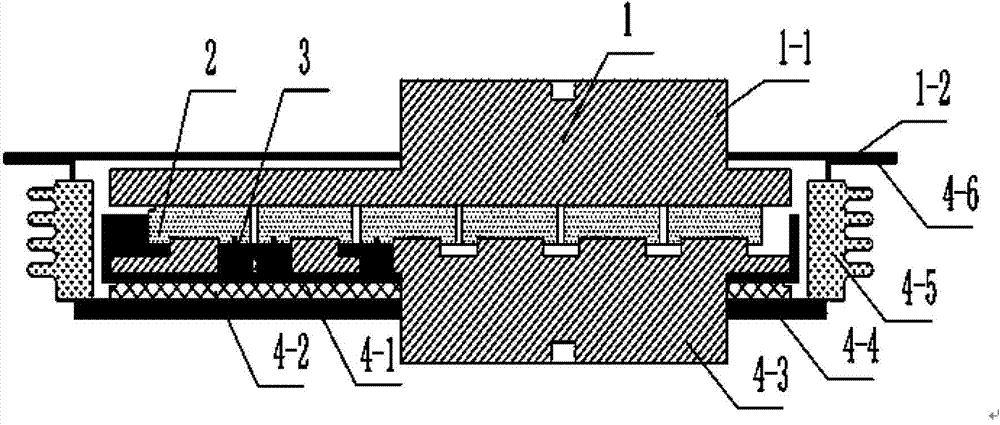

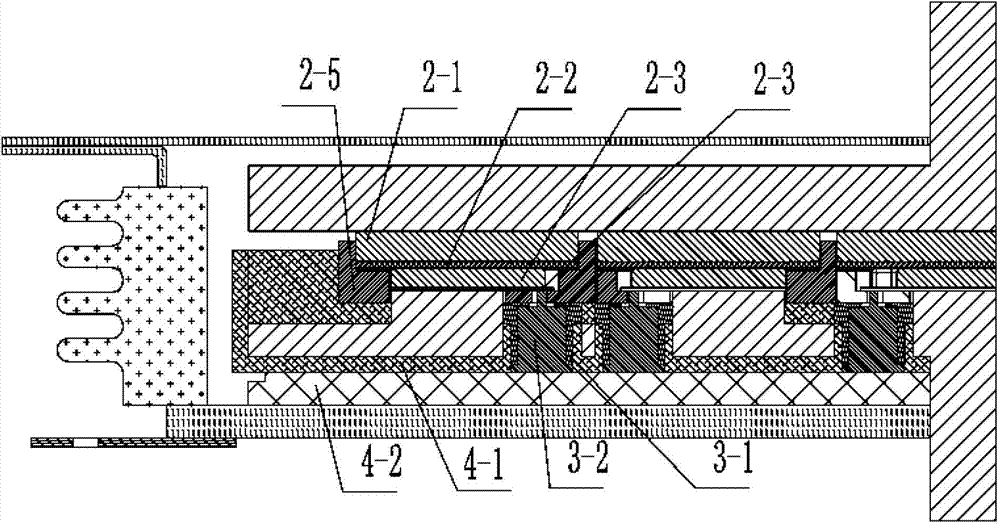

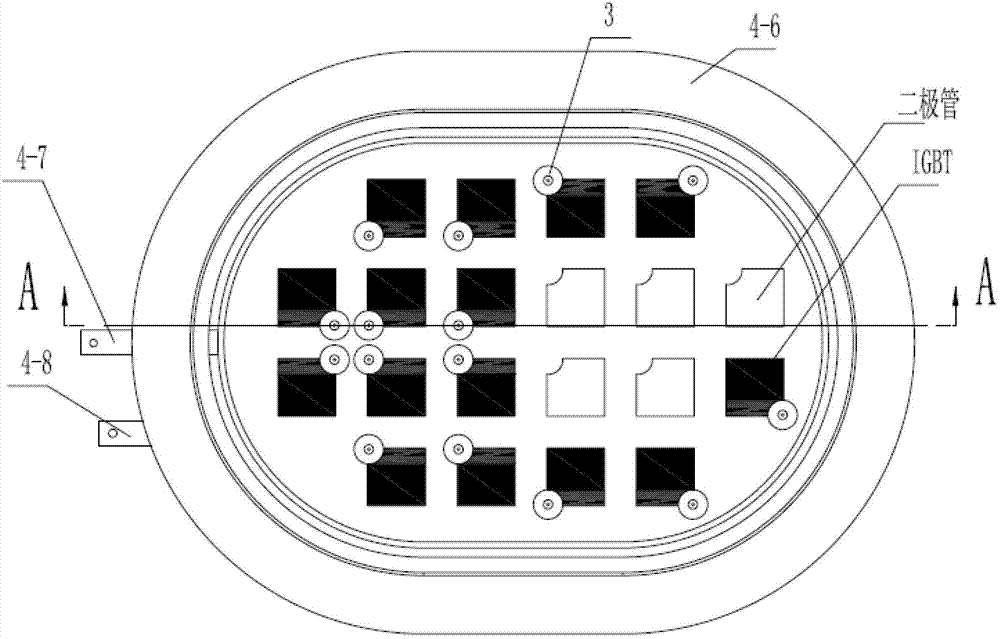

[0035] Structural schematic diagram and figure 1 The local enlarged diagrams are as follows figure 1 and 2 As shown, the frame plate is composed of an upper cover 1, a sub-module 2 (including an IGBT sub-module and a diode sub-module), a gate pin 3, and a lower base 4; the upper cover 1 is covered on the lower base 4, and the The sub-module 2 is set between the upper cover 1 and the lower base 4, and the gate pin 3 is set in the groove of the insulating bottom plate 4-1 in the lower base 4; specifically:

[0036] The upper cover 1 is mainly composed of a cover sun 1-1 and a cover copper block 1-2;

[0037] The sub-module 2 is composed of a top molybdenum sheet 2-1, a chip 2-2, a bottom molybdenum sheet 2-3, a conductive silver sheet 2-4 and a PBI high-performance plastic frame 2-5; the top view of the assembled sub-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com