Organic anti-oxidation method for bonding wires

A bonding wire and anti-oxidation technology, applied in the manufacturing of electrical components, electric solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of increased material hardness, unfavorable bonding, and increased production costs, and achieve excellent performance and preparation technology. Simple, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Example one: an organic anti-oxidation method for bonding wires, comprising the following steps:

[0040] (1) Pass the finished copper wire obtained by the wire drawing process through a pickling tank of about 10% dilute sulfuric acid solution, and the whole passing process is guaranteed to be about 30s.

[0041] (2) cleaning and drying the bonding wire after pickling with deionized water;

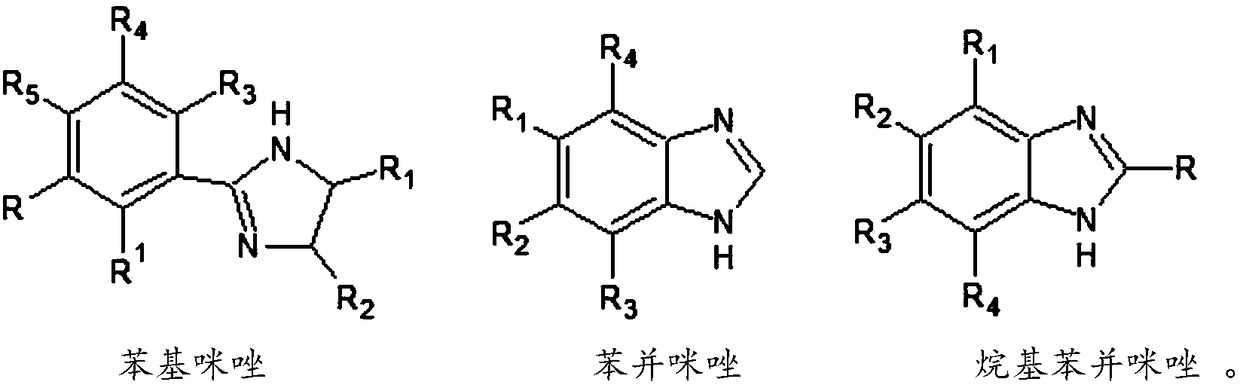

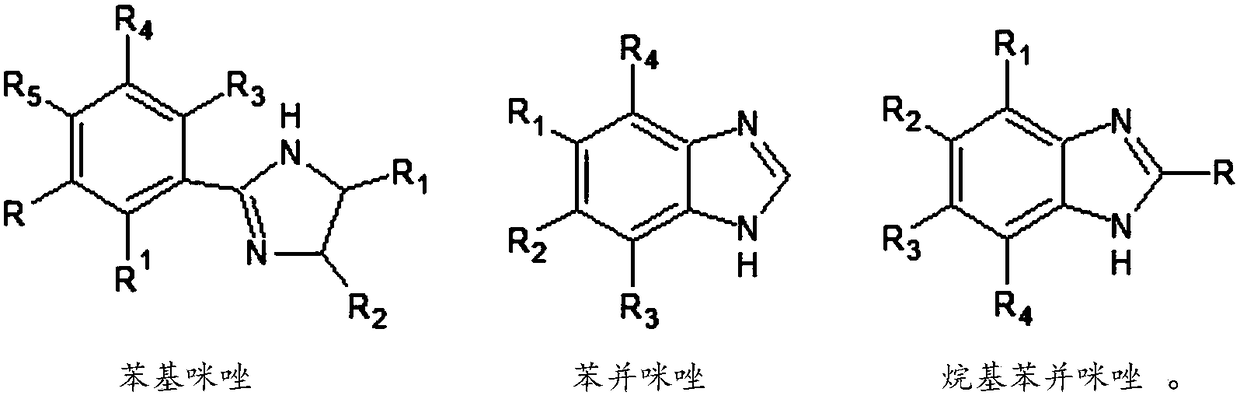

[0042] (3) Ensure that the temperature of the organic protective solution treatment tank is 25°C, the pH value is 8, the concentration of phenylimidazole is 1g / L, and the small molecule organic acid is 3.5mol / L, wherein acetic acid 60%, propionic acid 40%.

[0043] (4) Pass the above-mentioned dried bonding wire into the organic protection solution treatment tank, and ensure that the whole passing process is about 1s-3s;

[0044] (5) Dry the bonding wire after the coating treatment with hot air, and finally wind it up for storage.

[0045] Specifically, the specific anti-oxidation...

example 2

[0045] Specifically, the specific anti-oxidation time in air obtained in Example 1 can be maintained for about 8 months. Example two: an organic anti-oxidation method for bonding wires, comprising the following steps:

[0046] (1) Pass the finished copper wire obtained by the wire drawing process through a pickling tank of about 10% dilute sulfuric acid solution, and the whole passing process is guaranteed to be about 30s.

[0047] (2) cleaning and drying the bonding wire after pickling with deionized water;

[0048] (3) Ensure that the temperature of the organic protection solution treatment tank is 25°C, the pH value is 8, the concentration of benzimidazole is 1g / L, and the small molecule organic acid is 3.5mol / L, wherein acetic acid 60%, propionic acid 40%.

[0049] (4) Pass the above-mentioned dried bonding wire into the organic protection solution treatment tank, and ensure that the whole passing process is about 1s-3s;

[0050] (5) Dry the bonding wire after the coatin...

example 3

[0051] Specifically, the specific anti-oxidation time in air obtained in Example 2 can be maintained for about 10 months. Example three: an organic anti-oxidation method for bonding wires, comprising the following steps:

[0052] (1) Pass the finished copper wire obtained by the wire drawing process through a pickling tank of about 10% dilute sulfuric acid solution, and the whole passing process is guaranteed to be about 30s.

[0053] (2) cleaning and drying the bonding wire after pickling with deionized water;

[0054] (3) Ensure that the temperature of the organic protective solution treatment tank is 25°C, the pH value is 8, the concentration of alkylbenzimidazole is 1g / L, and the small molecule organic acid is 3.5mol / L, wherein acetic acid 60%, propionic acid 40% %.

[0055] (4) Pass the above-mentioned dried bonding wire into the organic protection solution treatment tank, and ensure that the whole passing process is about 1s-3s;

[0056] (5) Dry the bonding wire after t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com