Wear-resisting nitrile rubber thermoplastic elastomer power line jacket material as well as preparation method thereof

A thermoplastic elastomer, wear-resistant nitrile technology, applied in the direction of rubber insulators, conductors, circuits, etc., can solve the problem that the wear resistance cannot meet the demand, and achieve good market prospects, excellent tensile strength, excellent scratch resistance and wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

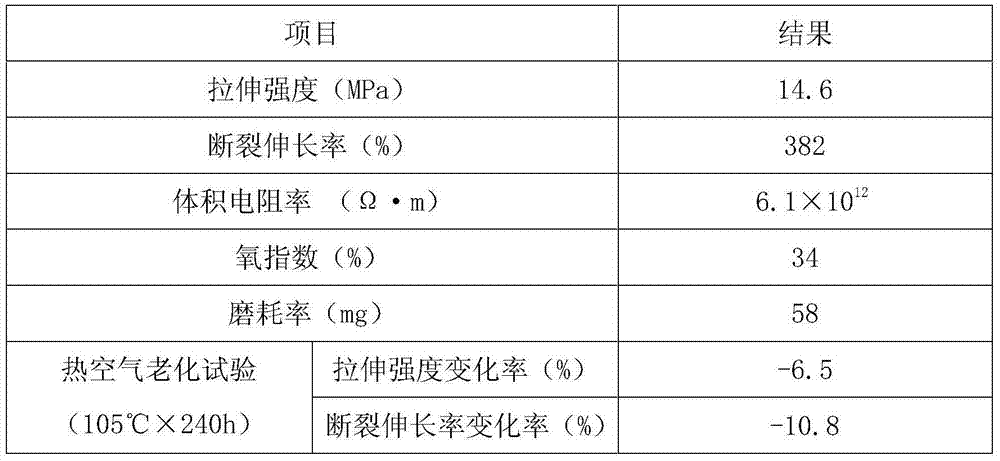

[0013] A wear-resistant nitrile rubber thermoplastic elastomer power cord sheath material, made of the following raw materials in weight (kg): nitrile rubber (N41) 65, XS-2 type PVC resin 20, POM resin 15, terpene resin 8. Trichloroethyl phosphate 10, dioctyl phthalate 7, calcium zinc composite stabilizer 1.5, active zinc oxide 2, stearic acid 1.5, white mineral oil 4, carbon black N33922, brucite powder 10, Coal gangue powder 10, nano calcite 8, anti-aging agent NBC1.5, anti-aging agent MB1, composite filler 4;

[0014] The preparation method of the composite filler is as follows: a. Take the following raw materials by weight (kg): pyrophyllite 10, diopside 8, opalite 6, N-2-(aminoethyl)-3-aminopropyltrimethoxy Silane 1.5, calcium lignosulfonate 2, sodium silicate 4, tourmaline slag 6, nano-diamond 4, germanium stone powder 3, sodium stearate 1.5; b, calcining pyrophyllite, diopside and opalite at 560°C 6h, cooling, crushing, passing through a 350-mesh sieve, mixing with tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com