A distributed Bragg feedback tunable laser and its manufacturing method

A technology for distributing Bragg and tuning lasers, used in lasers, laser parts, semiconductor lasers, etc., can solve the problem of low wavelength tuning efficiency, and achieve the effects of improving carrier injection concentration and low series resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

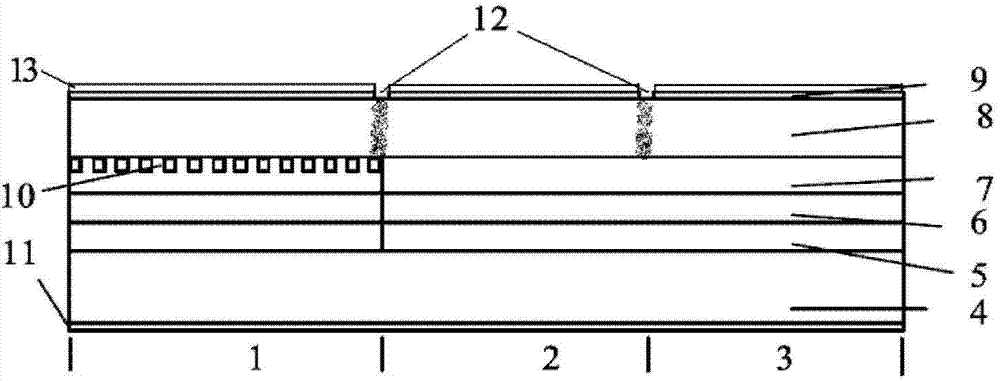

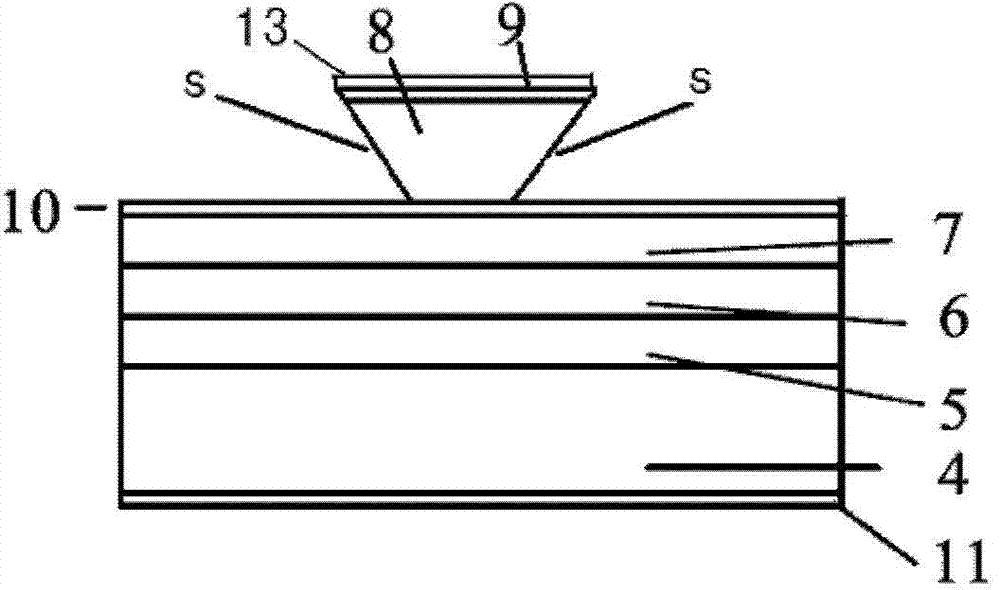

[0019] figure 1 It is a schematic diagram of the device material structure of the distributed Bragg feedback tunable laser of the present invention. figure 2 It is a cross-sectional view of the device inverted waveguide structure of the distributed Bragg feedback tunable laser of the present invention. see figure 1 , the laser is a stacked structure in the vertical direction, which sequentially includes a substrate 4, a lower waveguide layer 5, an active region layer 6, an upper waveguide layer 7, a cladding layer 8 and an electrical contact layer 9 from bottom to top. Layer 9 has a P-face electrode. Wherein the active layer 6 contains more than two quantum wells.

[0020] The distributed Bragg feedback tunable laser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com