Li-B base air suction material

A technology for getter materials and raw materials, applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of easy blockage of holes, loss of getter performance, danger, etc., and achieve the effect of broadening application fields and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

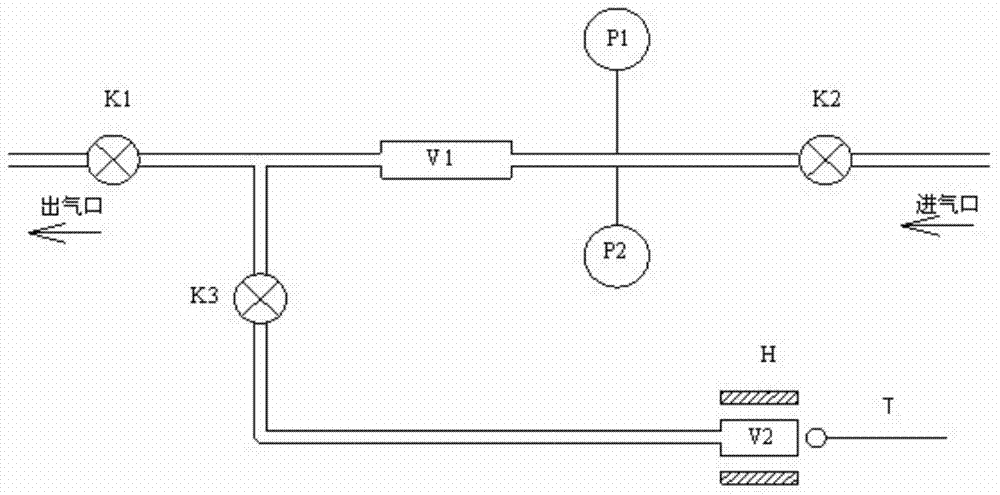

Method used

Image

Examples

Embodiment 1

[0045] 1. Use metal lithium ingots, fine boron powder, carbon powder, boron carbide powder, and magnesium powder according to the ingredients of 42Li-45B-12C-1Mg;

[0046] 2. Put the ingredients into an argon-protected resistance heating furnace and heat to 370 ° C, keep warm; stir for 1 hour after the metal is melted, so that the powder is completely immersed in it, and then cool to room temperature;

[0047] 3. The cooled ingot is billeted and cold-rolled at room temperature in an air with a relative humidity of less than 2% to form a 1×50 (mm) strip, which is stamped into a pre-alloyed disc with a diameter of 10mm. Obtain the in-situ suction piece;

[0048] 4. Put the pre-alloyed disc into an argon-protected resistance furnace and heat it to 700°C for 15 minutes. After cooling to room temperature, take it out and put it in the air with a relative humidity of less than 2% for 3 hours to obtain a surface-passivated getter piece. ;

[0049] 5. Both the in-situ suction sheet ...

Embodiment 2

[0052] 1 Use metal lithium ingot, fine boron powder, carbon powder, boron carbide powder, magnesium powder according to 40.1Li-41.6B-17.3C-1Mg ingredients;

[0053] 2 Put the ingredients into an argon-protected resistance heating furnace and heat to 370°C, keep warm;

[0054] 3 After the metal is melted, stir for 1 hour to fully immerse the powder in it, and then cool to room temperature; the cooled ingot is opened at room temperature and in air with a relative humidity of less than 2%, and cold-rolled to become 1×50( mm), which is stamped into a pre-alloyed disc with a diameter of 10mm to obtain an in-situ suction sheet;

[0055] 4. Put the pre-alloyed disc into an argon-protected resistance furnace and heat it to 700°C for 15 minutes. After cooling to room temperature, take it out and put it in the air with a relative humidity of less than 2% for 3 hours to obtain a surface-passivated getter piece. ;

[0056] 5. Both the in-situ suction sheet and the surface passivation su...

Embodiment 3

[0059] 1. Use metal lithium ingots, fine boron powder, carbon powder, boron carbide powder, and aluminum powder according to the ingredients of 41.8Li-44.4B-12.3C-1.5Al;

[0060] 2. Put the ingredients into an argon-protected resistance heating furnace and heat to 370°C to keep warm;

[0061] 3. After the metal is melted, stir for 1 hour to fully immerse the powder in it, and then cool to room temperature; the cooled ingot is opened at room temperature and in air with a relative humidity of less than 2%, and cold-rolled to become 1×50 (mm) of the strip, which is stamped into a pre-alloyed disc with a diameter of 10mm to obtain an in-situ suction sheet;

[0062] 4. Put the pre-alloyed wafer into an argon-protected resistance furnace and heat it to 700°C for 15 minutes. After cooling to room temperature, take it out and put it in the air with a relative humidity of less than 2% for 3 hours to obtain a surface-passivated getter piece. ;

[0063] 5. Both the in-situ suction shee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com