Halogen-free flame retardant polyolefin cable material of 125 DEG C with temperature resistance

A polyolefin cable material and temperature-resistant technology, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., can solve the problem of poor weather resistance, affecting the physical and mechanical properties and processing performance of cable materials, and low temperature resistance. Good and other problems, to achieve the effect of improved wear resistance, excellent non-flammability, and excellent flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

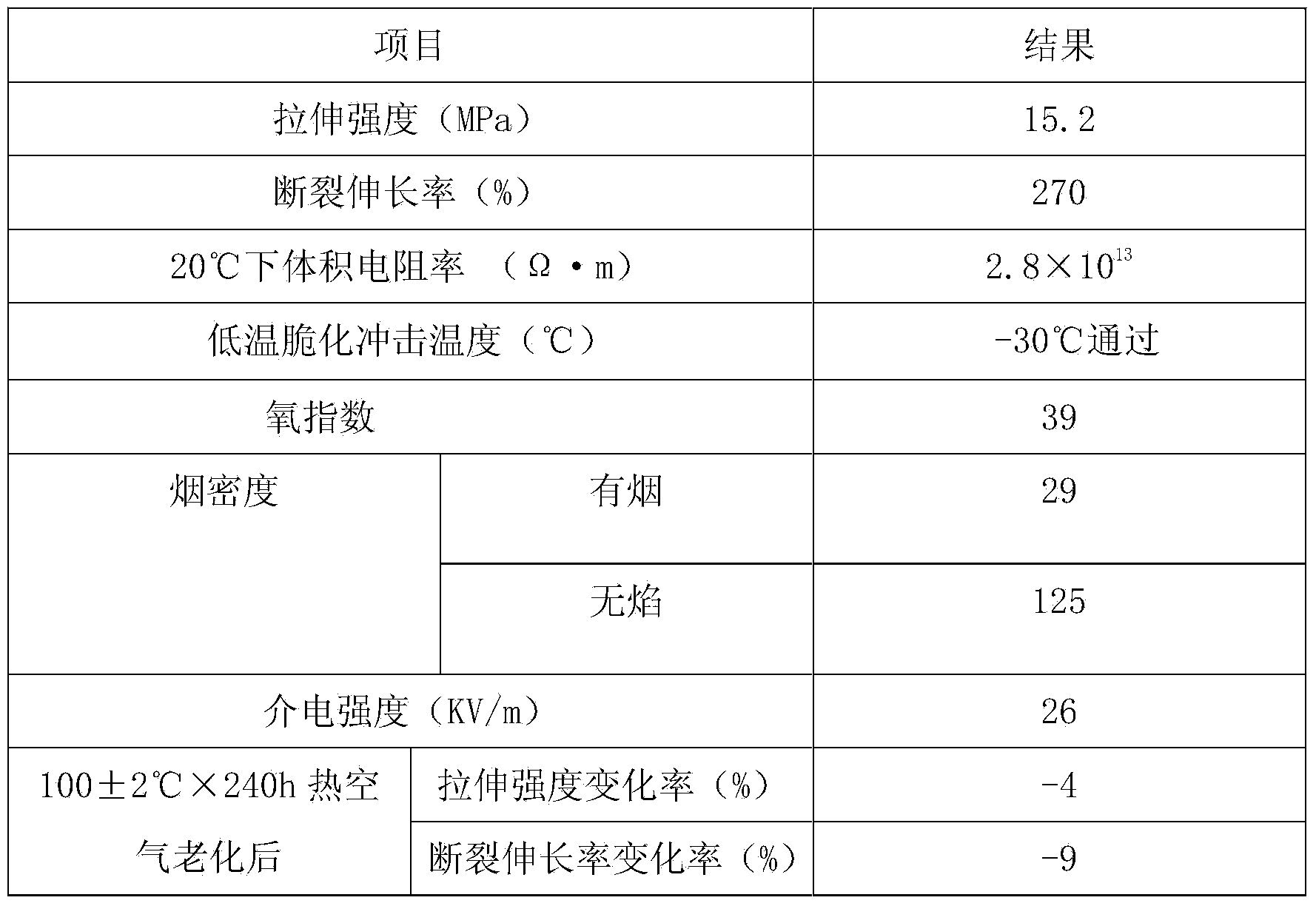

Examples

Embodiment Construction

[0012] Halogen-free flame-retardant polyolefin cable compound with a temperature resistance of 125°C is made of the following raw materials in weight (kg):

[0013] PE resin 45, ethylene-octene copolymer 20, ethylene-tetrafluoroethylene copolymer 15, compatibilizer 8, polyvinyl alcohol superfine powder 3, magnesium hydroxide 55, tributyl citrate 6, glycerin 5, boric acid Zinc 11, fluororubber 7, antioxidant 1682, crosslinking agent TAC1, aluminum hypophosphite 5, melamine cyanurate 2, allyl heptanoate 1, modified filler 9, wherein the modified filler is obtained by the following method Preparation Prepared from:

[0014] Calcinate the attapulgite at 550°C for 4 hours, take it out, add 4% sodium hydroxide solution and grind it for 1-2 hours, then add 14% hydrochloric acid solution, adjust the pH value to 4, and age for 12 hours. Add sodium hydroxide solution to adjust the pH of the grinding liquid to be neutral, filter, dry to obtain filler powder, then add tea tree essential ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com