Preparation method of nano flaky ferroelectric material for photocatalysis

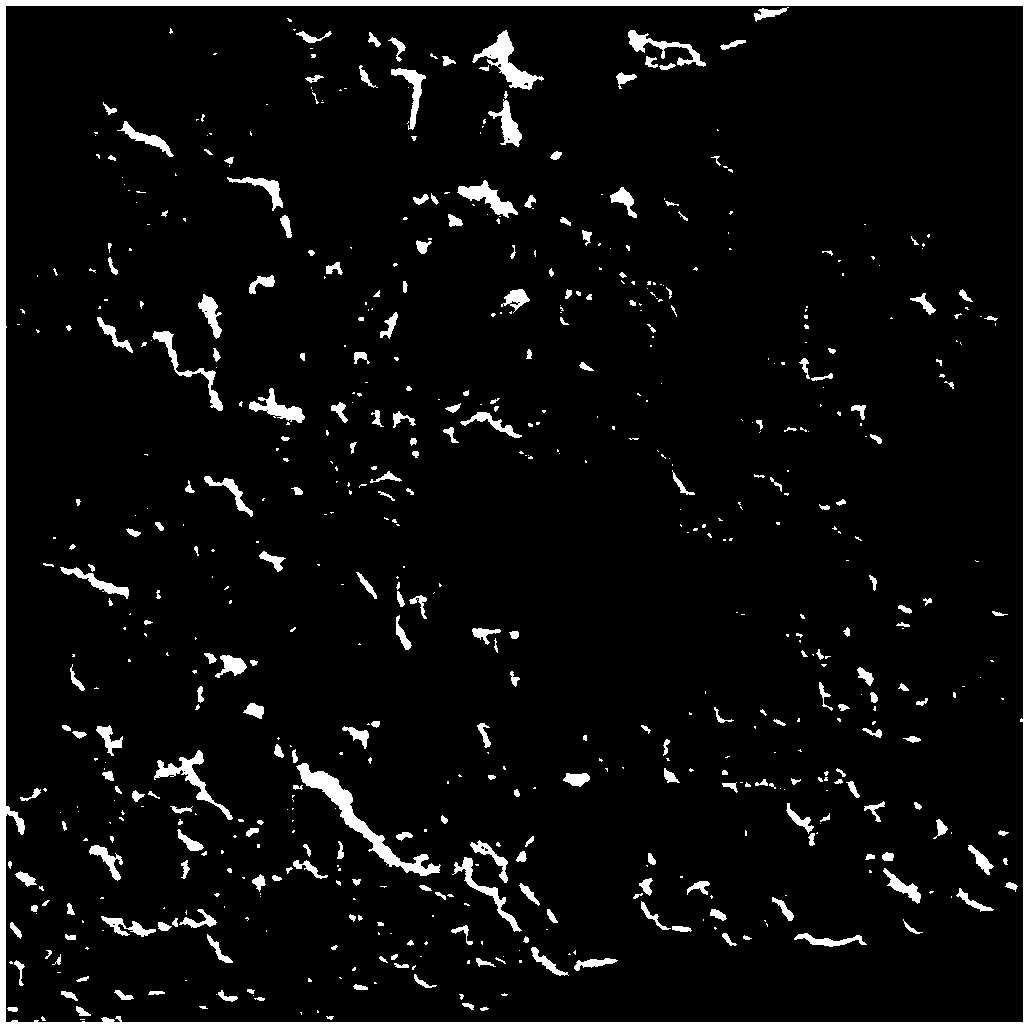

A technology of nano-flaky and ferroelectric materials, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve serious powder agglomeration, excessively large powder particles, and powder crystallization In order to avoid problems such as poor stability, achieve the effects of reducing agglomeration, good crystallinity, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

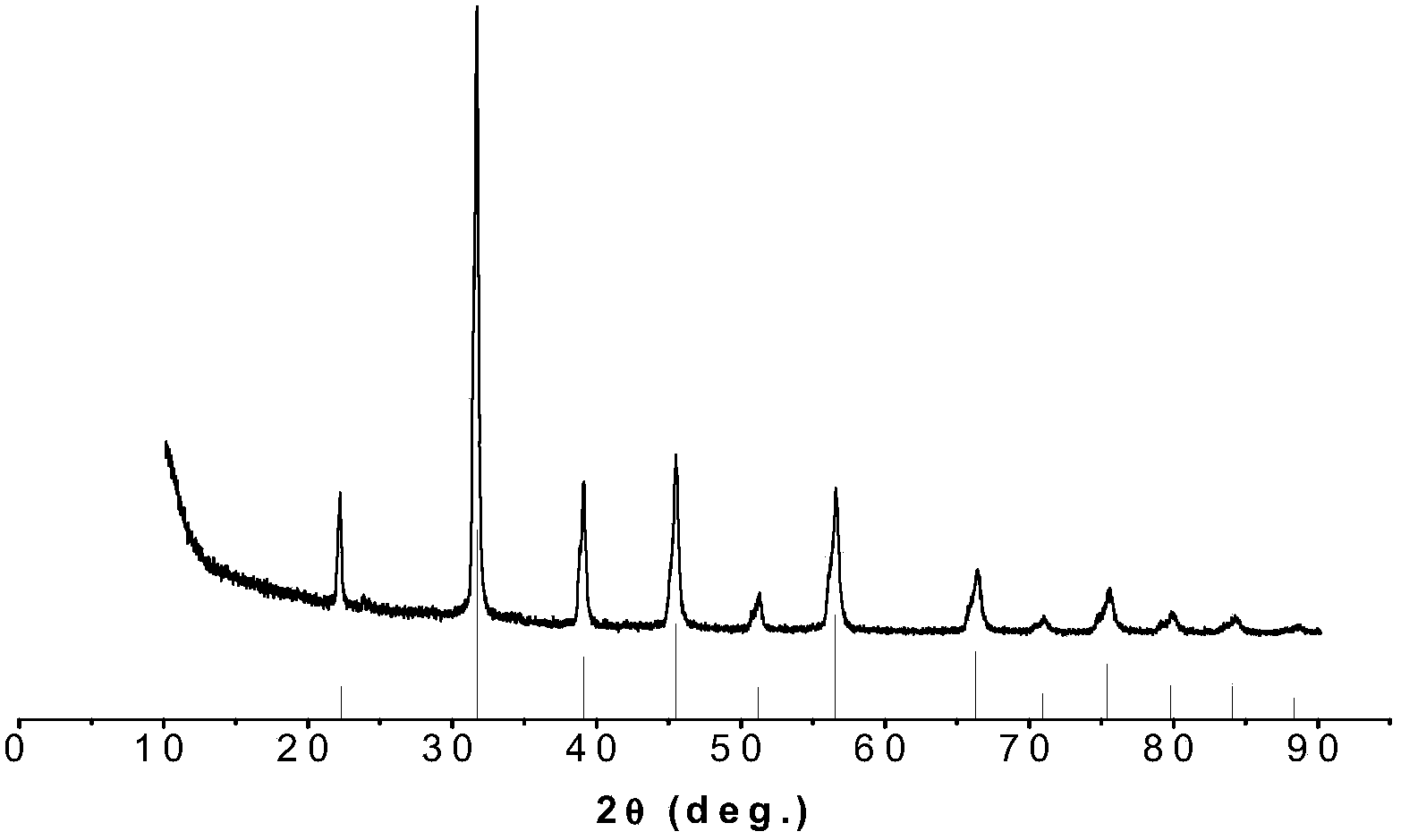

Embodiment 1

[0031] A kind of preparation method of photocatalytic nano flake ferroelectric material namely barium strontium titanate, with Ba 0.7 Sr 0.3 TiO 3 For example, calculated by molar ratio, barium in barium salt: strontium in strontium salt: titanium in butyl titanate: sodium hydroxide is 0.7:0.3:1:4; the barium salt used is BaCl 2 .2H 2 O, strontium salt as SrCl 2 .2H 2 O.

[0032] Weigh 1.7186g BaCl 2 .2H 2 O, 0.8039g SrCl 2 .2H 2 O, transfer the two raw materials into the Erlenmeyer flask, add 25ml deionized water and stir to dissolve, add 1.6667g NaOH to the above solution, stir and dissolve to form a strong alkali environment.

[0033] Use a measuring cylinder to take 3.4ml of butyl titanate, add an appropriate amount of absolute ethanol to form an ethanol solution of butyl titanate, pour the ethanol solution into the above-mentioned Erlenmeyer flask, and stir for 30 minutes on a constant temperature magnetic stirrer at a speed of 600r / min. Then transfer the suspen...

Embodiment 2

[0035] A kind of preparation method of photocatalytic nano flake ferroelectric material namely barium strontium titanate, with Ba 0.7 Sr 0.3 TiO 3 For example, calculated by molar ratio, barium in barium salt: strontium in strontium salt: titanium in butyl titanate: sodium hydroxide is 0.7:0.3:1:4; the barium salt used is BaCl 2 .2H 2 O, strontium salt as SrCl 2 .2H 2 O.

[0036] Weigh 1.7186g BaCl 2 .2H 2 O, 0.8039g SrCl 2 .2H 2O, transfer the two raw materials into the Erlenmeyer flask, add 25ml deionized water and stir to dissolve, add 1.6667g NaOH to the above solution, stir and dissolve to form a strong alkali environment.

[0037] Use a measuring cylinder to take 3.4ml of butyl titanate, add an appropriate amount of absolute ethanol to form an ethanol solution of butyl titanate, pour the ethanol solution into the above-mentioned Erlenmeyer flask, and stir for 30 minutes on a constant temperature magnetic stirrer at a speed of 600r / min. Then transfer the suspens...

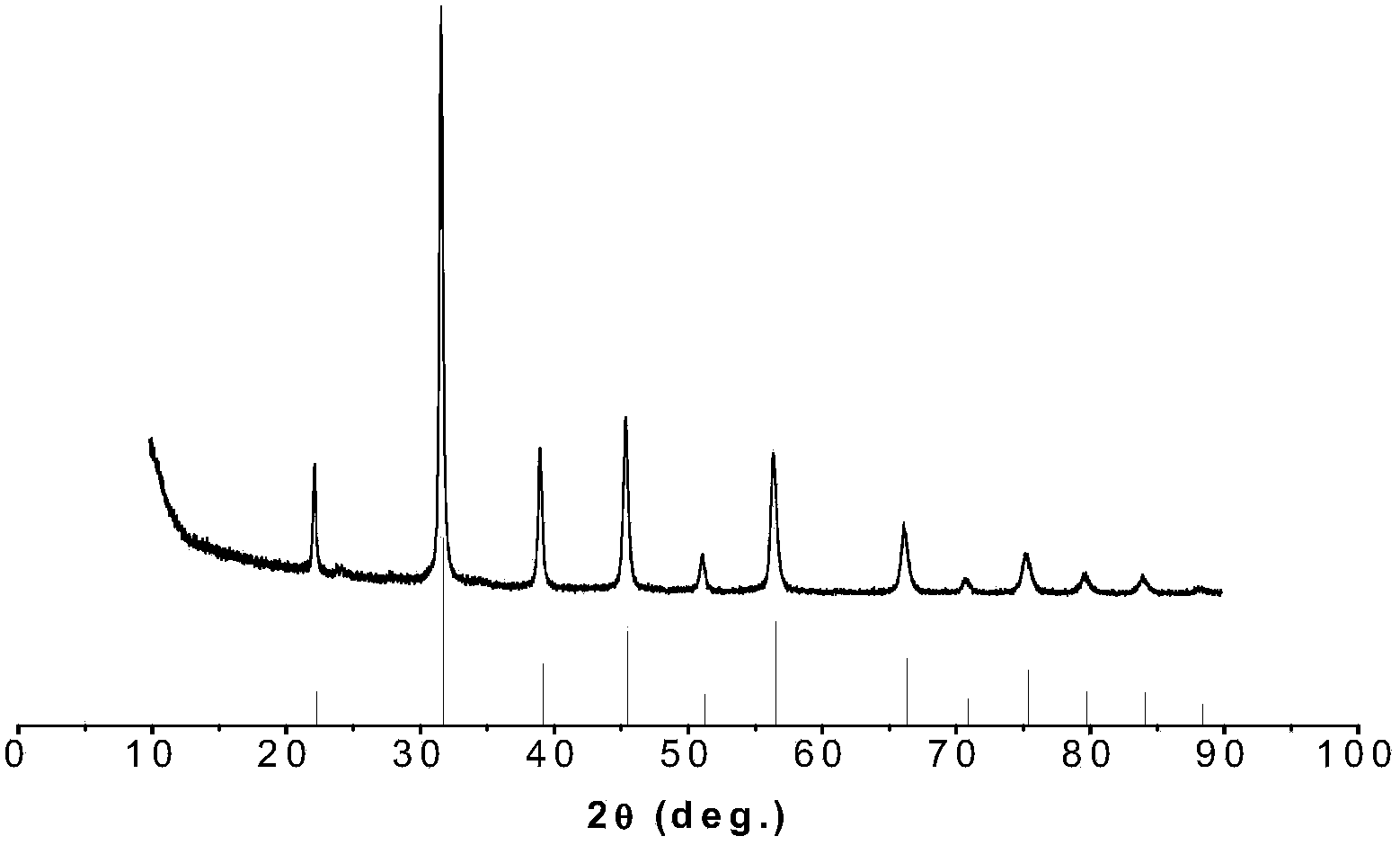

Embodiment 3

[0039] A kind of preparation method of photocatalytic nano flake ferroelectric material namely barium strontium titanate, with Ba 0.7 Sr 0.3 TiO 3 For example, calculated by molar ratio, barium in barium salt: strontium in strontium salt: titanium in butyl titanate: sodium hydroxide is 0.7:0.3:1:4; the barium salt used is Ba(NO 3 ) 2 , the strontium salt is Sr(NO 3 ) 2 .

[0040] Weigh 1.8295g Ba(NO 3 ) 2 , 0.6349g Sr(NO 3 ) 2 , Transfer the two raw materials into a Erlenmeyer flask, add 25ml deionized water and stir to dissolve, add 1.6667g NaOH to the above solution, stir and dissolve to form a strong alkali environment.

[0041] Use a measuring cylinder to take 3.4ml of butyl titanate, add an appropriate amount of absolute ethanol to form an ethanol solution of butyl titanate, pour the ethanol solution into the above-mentioned Erlenmeyer flask, and stir for 30 minutes on a constant temperature magnetic stirrer at a speed of 600r / min. Then transfer the suspension i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com