High-conductivity graphene and graphene conducting film, and preparation method thereof

A graphene, high conductivity technology, applied in the field of materials, can solve the problems of limited electrode surface modification methods, complicated production process, expensive silver, etc., to achieve easy recycling and harmless treatment, high production efficiency, conductivity and film formation good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

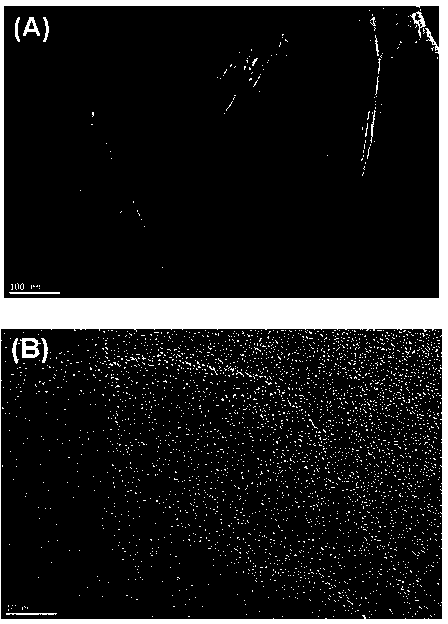

Image

Examples

Embodiment 1

[0032] Add 10mL of 98% (mass percentage) sulfuric acid into a 100mL round bottom bottle, heat the oil bath to 120°C, and slowly add 0.2g of potassium peroxodisulfate and 2g of phosphorus pentoxide until completely dissolved under stirring conditions, then lower the temperature Lower to 100°C, slowly add 1 gram of graphite powder, react for 10 hours, dilute the reaction mixture 50 times with water, wash on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, and then place it in 200 mL of 38% (mass percentage) Stir in hydrochloric acid for more than 12 hours to remove excess mixed oxidant, dilute the reaction mixture 50 times with water, wash with water on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, and dry the solid product at 60°C for 5 hours to obtain the prepared product. Graphite oxide powder.

Embodiment 2

[0034] Add 200mL of 98% (mass percentage) sulfuric acid into a 500mL round bottom bottle, heat the oil bath to 60°C, and slowly add 5g of potassium dichromate and 10g of phosphorus pentoxide until they are completely dissolved under stirring conditions, and then lower the temperature Cool down to 40°C, slowly add 10 grams of graphite powder, react for 10 hours, dilute the reaction mixture 50 times with water and wash it on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, then place it in 200 mL of 38% (mass percentage) Stir in hydrochloric acid for more than 12 hours to remove excess mixed oxidant, dilute the reaction mixture 50 times with water, wash with water on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, and dry the solid product at 60°C for 5 hours to obtain the prepared product. Graphite oxide powder.

Embodiment 3

[0036] Add 100mL of 98% (mass percentage) sulfuric acid into a 200mL round bottom bottle, heat the oil bath to 180°C, and slowly add 10g of cerium oxide and 1g of phosphorus pentoxide until completely dissolved under stirring conditions, then lower the temperature to To 160°C, add 5 grams of graphite powder slowly, react for 1 hour, dilute the reaction mixture 50 times with water and wash it on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, then place it in 200 mL of 38% (mass percentage) hydrochloric acid Stir in medium for more than 12 hours to remove excess mixed oxidant, dilute the reaction mixture 50 times with water, wash with water on a mixed cellulose filter membrane with a pore size of 0.22 μm until the filtrate is neutral, and dry the solid product at 60°C for 5 hours to obtain preoxidation graphite powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com