Silane crosslinking halogen-free flame retardant polyvinyl chloride cable material

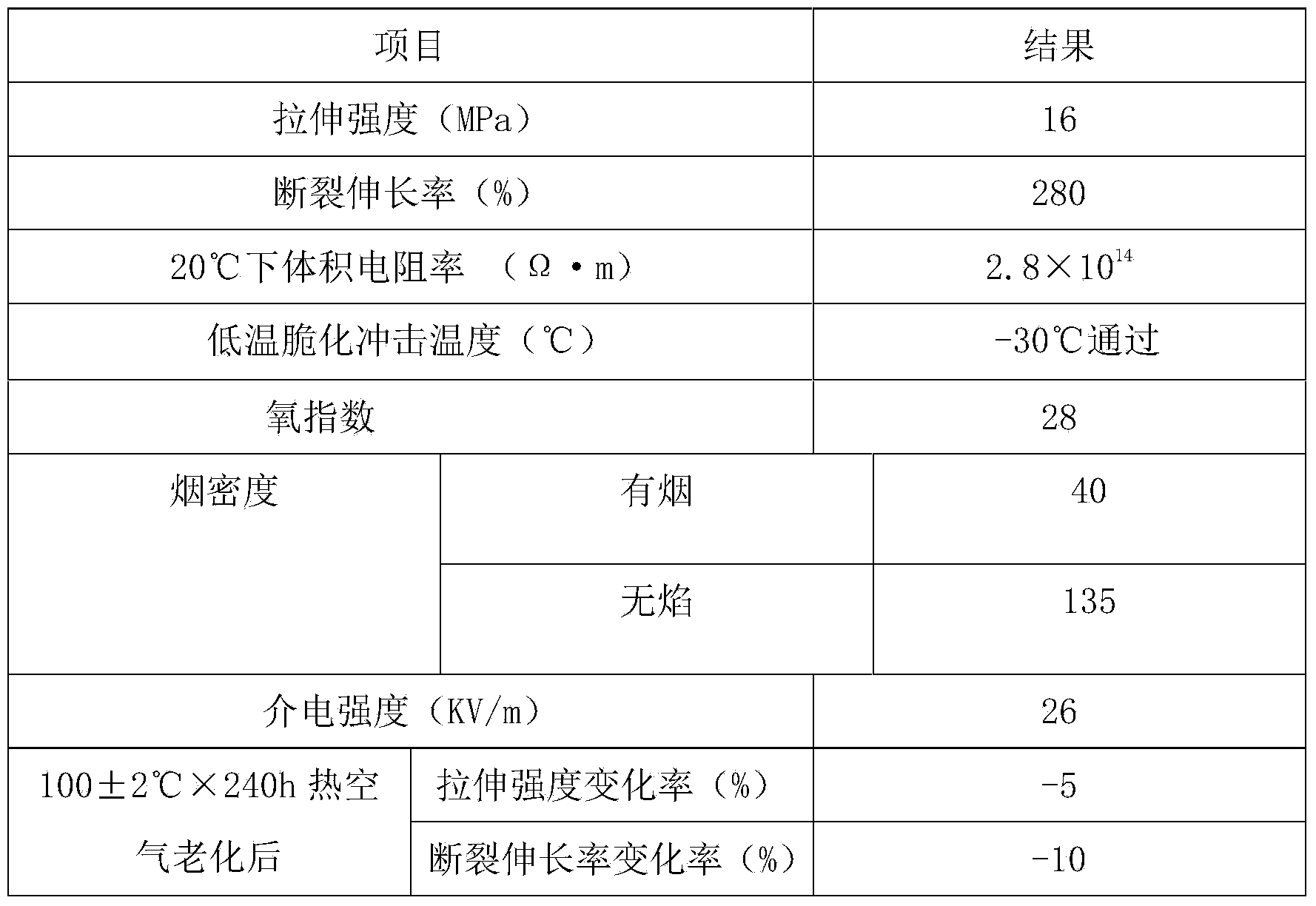

A flame-retardant polyvinyl chloride and silane cross-linking technology, which is applied in the field of cable materials, can solve problems affecting the physical and mechanical properties and processing of cable materials, and achieve good electrical properties, good mechanical properties, and good insulation properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] A silane cross-linked halogen-free flame-retardant polyvinyl chloride cable material, prepared from the following component raw materials by weight (kg):

[0018] Polyvinyl chloride resin 75, acrylic graft modified acrylic resin 15, butyl acetate 2, ethyl trifluoroacetate 1, zinc borate 9, molybdenum trioxide 3, copper oxide 1, magnesium hydroxide 11, ammonium polyphosphate 9, Triethyl citrate 8, fumarate 4, TCEP flame retardant plasticizer (tris(β-chloroethyl) phosphate) 14, calcium zinc stabilizer 1, calcium stearate 2, zinc stearate 0.3 , light calcium carbonate 9, talcum powder 4, calcined clay 9, magnesium carbonate 3, glass beads 0.3, dioctadecyl alcohol ester 1, polyethylene wax 2, tribasic lead sulfate 0.3, heavy calcium carbonate 25 , barium stearate 4, dibasic lead stearate 0.6, vinyl triethoxysilane 0.8, modified filler 10,

[0019] Among them, the modified filler is prepared by the following method: a. Take the following raw materials by weight (kg): kaolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com