Polymer single-ion electrolyte and preparation method thereof

A polymer and electrolyte technology, applied in circuits, electrical components, secondary batteries, etc., can solve the problems of low room temperature conductivity, poor mechanical strength and film-forming performance, cumbersome synthesis steps, etc., and achieve high room temperature conductivity, mechanical Good strength and film-forming performance, high lithium ion transfer number effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-10

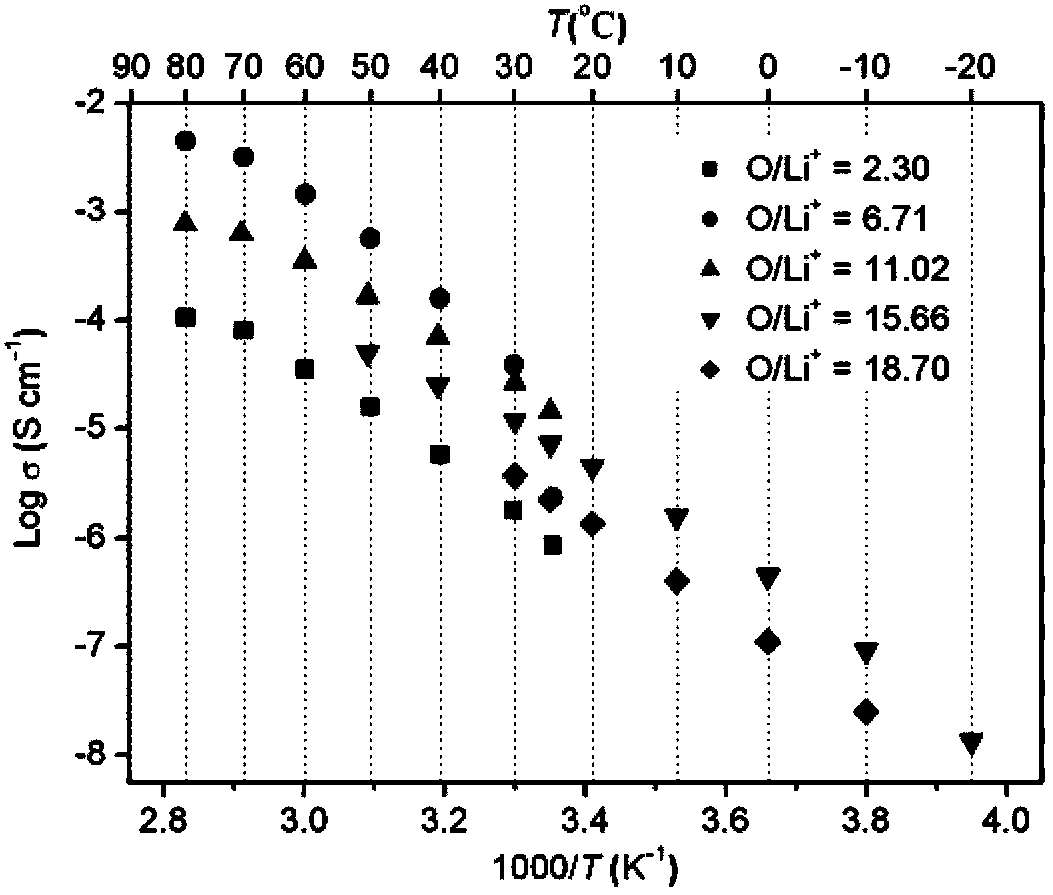

[0032] Embodiment 1-10 is the preparation of polymer single ion electrolyte

Embodiment 1

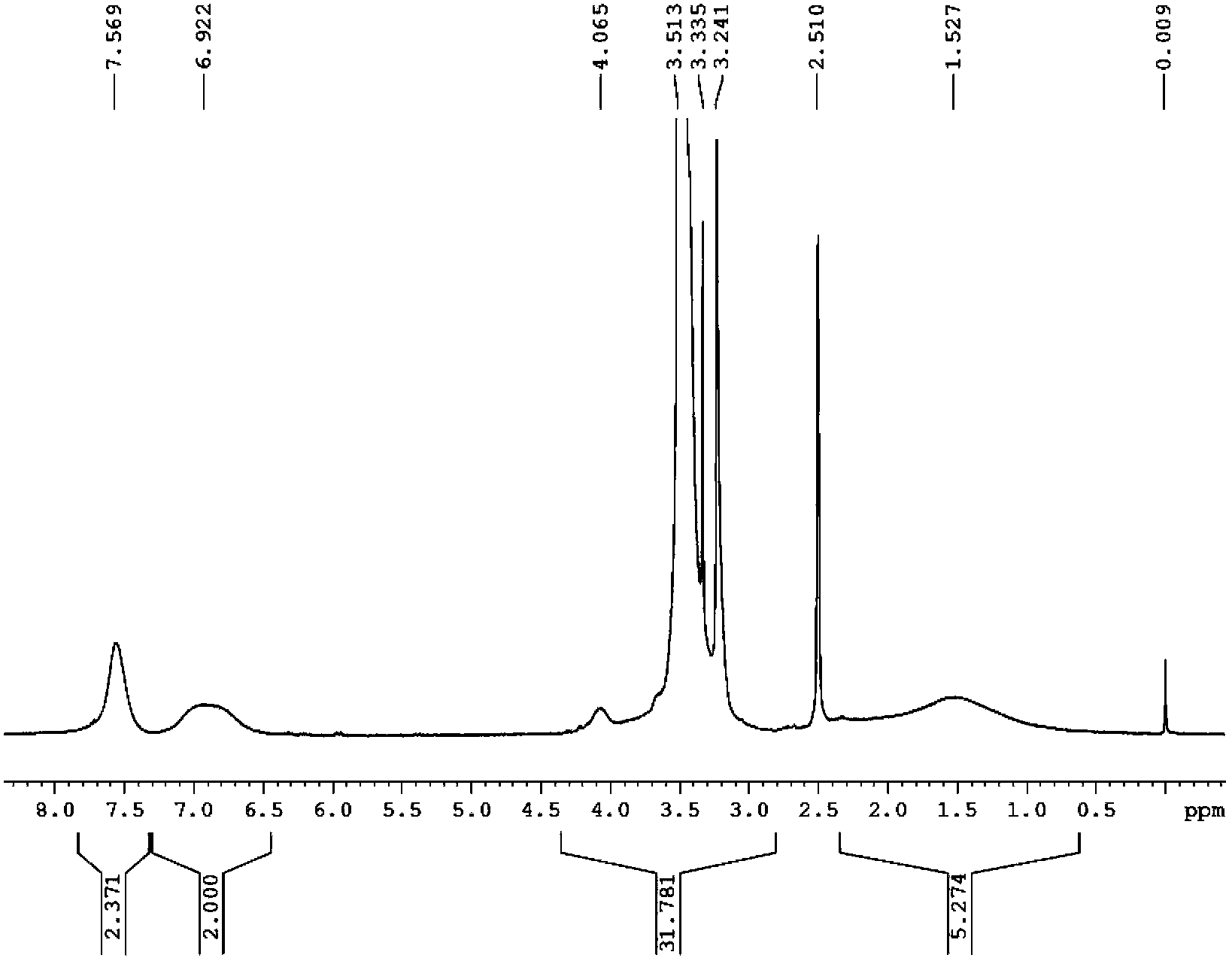

[0033] Example 1: Preparation of (p-vinylbenzenesulfonyl) (fluorosulfonyl) lithium imide (LiSFSI) and methoxytriethylene glycol acrylate (MPEGA, n=3) copolymer (electrolyte 1)

[0034] Add 1.32g (5.0mmol) (p-vinylbenzenesulfonyl)(fluorosulfonyl)imide lithium (LiSFSI) monomer, 1.09g (5.0mmol) methoxytriethylene glycol acrylic acid to a 25mL reaction flask Ester (MPEGA, n=3), 0.0042 g (0.025 mmol) azobisisobutyronitrile (AIBN) and 2.5 mL dry DMF. Pass argon to exhaust oxygen for 2h, and react at 50°C for 8h. After the reaction was completed, cool to room temperature, and slowly drop the reaction solution into excess diethyl ether under stirring to precipitate a viscous solid, pour out the upper layer of diethyl ether slowly, and repeat the dissolution and precipitation three times. A gel-like polymer solid was obtained; the viscous polymer was vacuum-dried at 80° C. for 8 hours to obtain 1.6 g of random copolymer (electrolyte 1). Through NMR characterization, the actual oxyeth...

Embodiment 2

[0036] Embodiment 2: (p-vinylbenzenesulfonyl) (trifluoromethylsulfonyl) lithium imide (LiSTFSI) and methoxy octaethylene glycol acrylate (MPEGA, n=8) copolymer (electrolyte 2) preparation

[0037] Add 1.32g (4.1mmol) (p-vinylbenzenesulfonyl)(trifluoromethylsulfonyl)imide lithium (LiSTFSI) monomer, 1.80g (3.7mmol) methoxy octaacetal to a 25mL reaction flask Diol (400) acrylate (MPEGA, n=8), 0.013 g (0.08 mmol) azobisisobutyronitrile (AIBN) and 5 mL dry DMF. Pass argon to exhaust oxygen for 2h, and react at 60°C for 15h. After the reaction was completed, cool to room temperature, and slowly drop the reaction solution into excess diethyl ether under stirring to precipitate a viscous solid, pour out the upper layer of diethyl ether slowly, and repeat the dissolution and precipitation three times. A gel-like polymer solid was obtained; the viscous polymer was vacuum-dried at 80° C. for 8 hours to obtain 42 g of a random copolymer (electrolyte 2).

[0038] Dissolve 42 g of the ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com