Preparation method of trace element composite doping modified tin antimony oxide (ATO) ceramic target

A composite doping and ceramic target technology is applied in the field of preparation of trace element composite doping modified tin antimony oxide ceramic targets, which can solve the problems of expensive equipment, low yield, long sintering time and the like, and achieves good electrical conductivity. , high conductivity, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

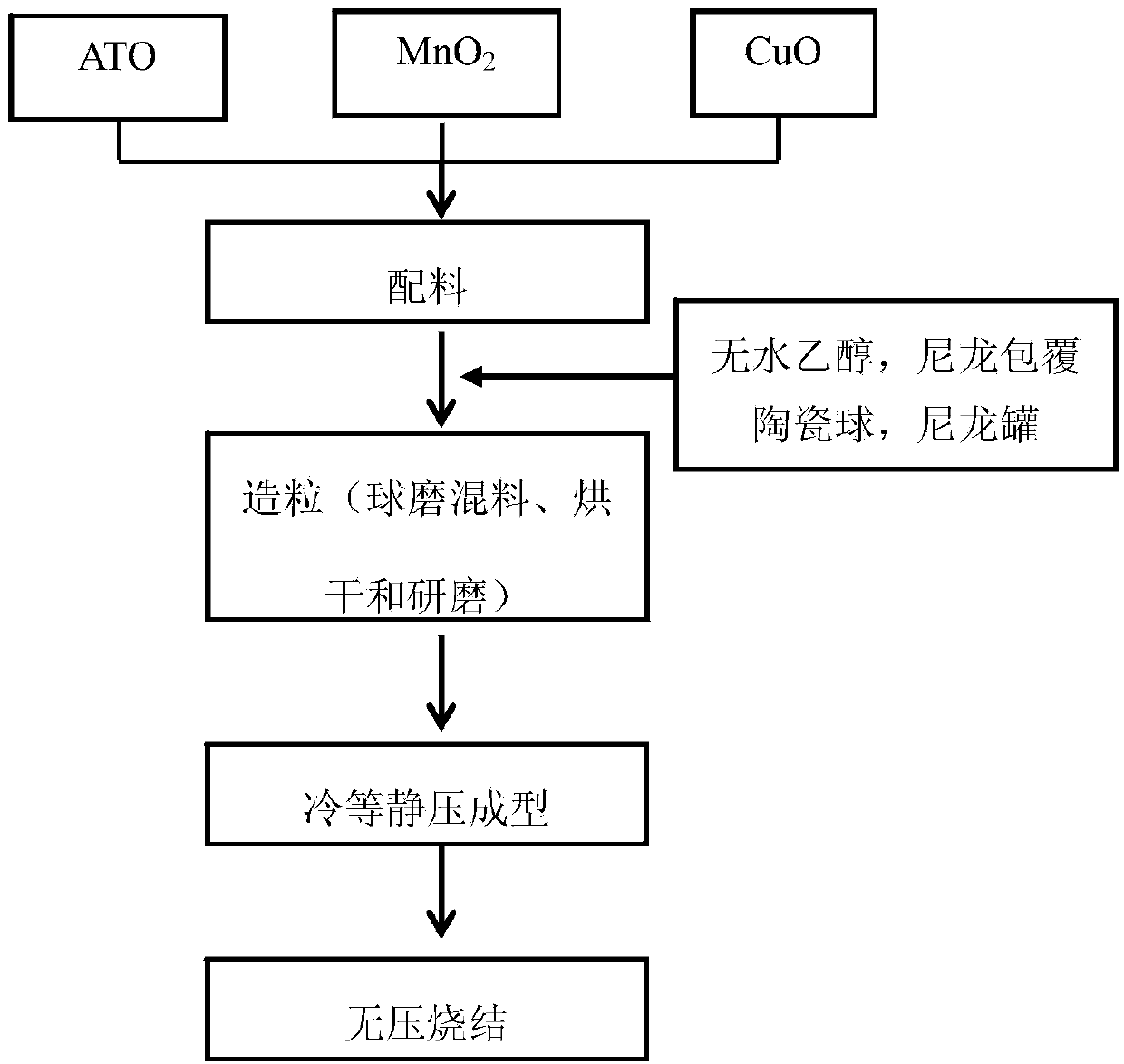

[0027] Such as figure 1 Shown, the preparation method of modified tin antimony oxide ceramic target, it comprises the following steps:

[0028] 1) Ingredients: 0.1μm, 99% purity and Sb in electronic balance 2 o 3 ATO powder with a powder mass ratio of 1.0% to the total mass, CuO powder with a purity of 1 μm and a purity of 98%, and MnO powder with a purity of 0.1 μm and a purity of 98%. 2 The powder is weighed according to the mass ratio of 100:0.95:0.05 (the mass of ATO powder is 500g) and set aside.

[0029] 2) Granulation: according to ATO powder, CuO powder and MnO 2 Powder: organic solvent: mass ratio of mixing ball = 1:2:1, ATO powder, CuO powder, MnO 2 The powder, the organic solvent and the mixing ball are put into a ball milling tank and mixed in a planetary ball mill; the organic solvent is absolute ethanol, the mixing ball is a nylon-coated ceramic ball, and the ball milling tank is Nylon tank; the speed of the planetary ball mill is 200 rpm, and the ball milli...

Embodiment 2

[0034] Such as figure 1 Shown, the preparation method of modified tin antimony oxide ceramic target, it comprises the following steps:

[0035] 1) Ingredients: 1μm, 99% purity and Sb in electronic balance 2 o 3 The powder mass accounts for 0.1% ATO powder, 0.1 μm CuO powder with a purity of 98%, and 1 μm MnO powder with a purity of 98%. 2 The powder is weighed according to the mass ratio of 100:0.05:0.95 (the mass of ATO powder is 500g) and set aside.

[0036] 2) Granulation: according to ATO powder, CuO powder and MnO 2 Powder: organic solvent: mass ratio of mixing ball = 1:2:1, ATO powder, CuO powder, MnO 2 The powder, the organic solvent and the mixing ball are put into a ball milling tank and mixed in a planetary ball mill; the organic solvent is absolute ethanol, the mixing ball is a nylon-coated ceramic ball, and the ball milling tank is Nylon tank; planetary ball mill at 200 rpm, ball milling time 4 hours. Pour the uniformly mixed slurry after ball milling into a ...

Embodiment 3

[0041] Such as figure 1 Shown, the preparation method of modified tin antimony oxide ceramic target, it comprises the following steps:

[0042] 1) Ingredients: 0.1μm, 99% purity and Sb in electronic balance 2 o 3 The powder mass accounts for 0.5% ATO powder, 0.1 μm CuO powder with a purity of 98%, and 0.1 μm MnO powder with a purity of 98%. 2 The powder is weighed according to the mass ratio of 100:0.25:0.25 (the mass of ATO powder is 500g) and set aside.

[0043] 2) Granulation: according to ATO powder, CuO powder and MnO 2 Powder: organic solvent: mass ratio of mixing ball = 1:2:1, ATO powder, CuO powder, MnO 2 The powder, the organic solvent and the mixing ball are put into a ball milling tank and mixed in a planetary ball mill; the organic solvent is absolute ethanol, the mixing ball is a nylon-coated ceramic ball, and the ball milling tank is Nylon tank; the speed of the planetary ball mill is 200 rpm, and the ball milling time is 8 hours. Pour the uniformly mixed s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com