Novel green extraction technology for cordyceps polysaccharide

A technology of Cordyceps polysaccharides and Cordyceps, which is applied in the field of microorganisms, can solve the problems of production cost and product quality impact, consumption of alcohol and labor, and low removal rate of monosaccharides, so as to improve mycelium yield, low supporting cost, and simple sugar removal. The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

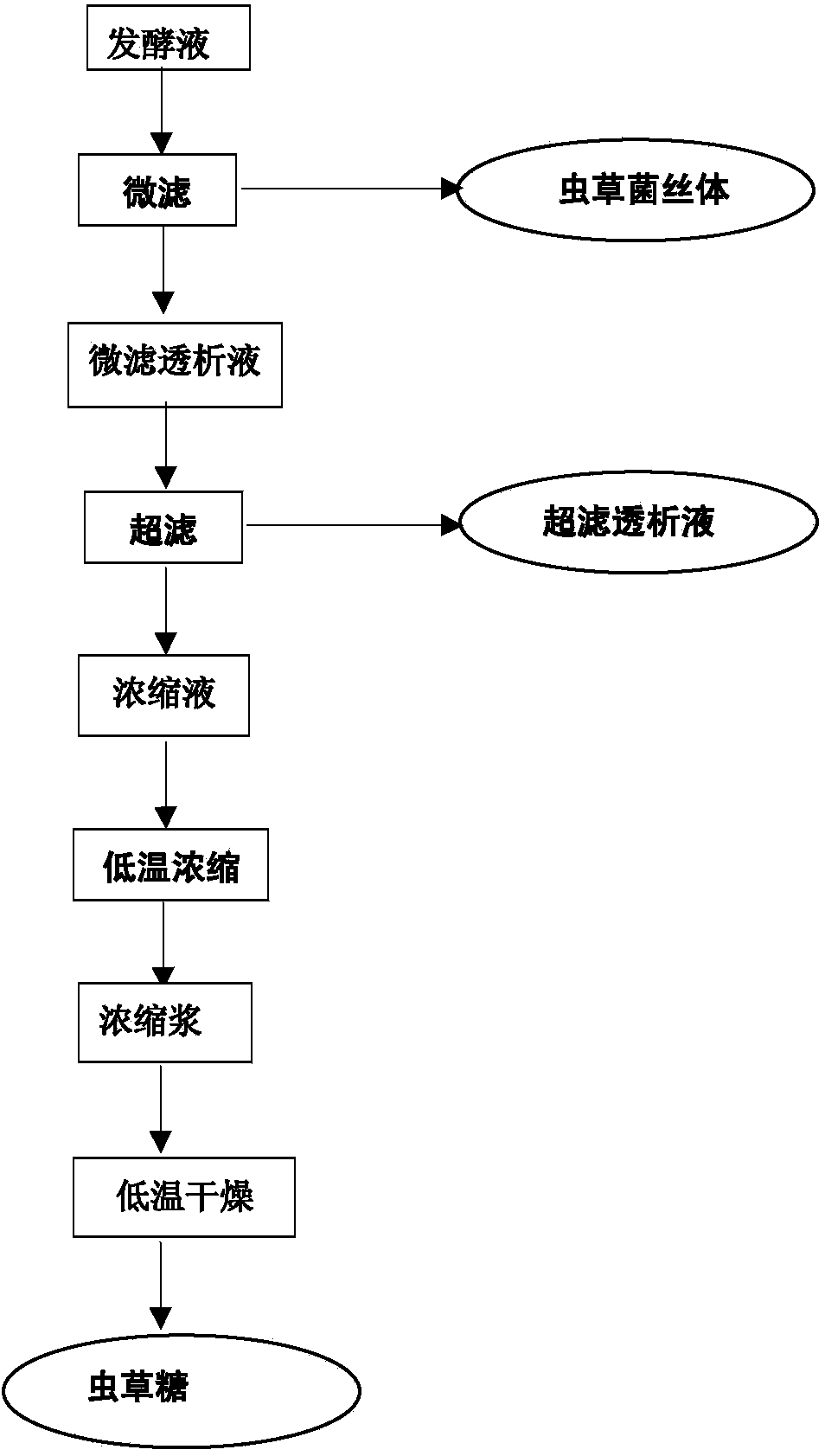

[0025] Cordyceps polysaccharide extraction method of the present invention is carried out according to the following steps:

[0026] 1. Source of Cordyceps fermented liquid: provided and identified by China Agricultural Microorganism Culture Collection Management Center, Cordyceps, preservation number ACCC51700. Transfer the strain to the slant medium for conventional culture at 26-28°C for about 30 hours to obtain the activated Cordyceps strain; inoculate the activated Cordyceps strain into the seed medium, wherein the composition of the seed medium is 8% sucrose, 4% yeast powder, 3% peptone, 0.4% potassium dihydrogen phosphate, 0.09% magnesium sulfate, 0.1% defoamer, prepared with water, with natural pH value, shaking culture at 26-28°C for about 30 hours to obtain the first-class seed liquid of Cordyceps; inoculate the first-class seed liquid Enter the secondary seed medium, wherein the secondary seed medium consists of 8% sucrose, 2% yeast powder, 2% peptone, 0.4% potassiu...

Embodiment 2

[0032] Cordyceps polysaccharide extraction method of the present invention, carry out according to the following steps:

[0033] 1, microfiltration filtration: the Cordyceps fermented liquid 7500Kg (fermentation liquid solid content is 3.7%) among the embodiment 1 is filtered by microfiltration, obtains the wet mycelium of the microfiltration dialysate 6372Kg of Cordyceps sinensis and 1128Kg (water content is 76.1%), the light transmittance of the dialysate is 84%, and the wet mycelium can be directly dried and pulverized at low temperature to obtain fermented Cordyceps powder. The membrane material used for microfiltration is a ceramic membrane with a pore size of 100nm. The specific process conditions are: the operating temperature is 50-60°C, the inlet pressure is 2.0bar, the outlet pressure is 1.0bar, and the pressure difference is 1.0bar.

[0034]2. Ultrafiltration filtration: 6372Kg of the microfiltration dialysate obtained in step 1 is filtered by ultrafiltration to obt...

Embodiment 3

[0038] Cordyceps polysaccharide extraction method of the present invention, carry out according to the following steps:

[0039] 1. Microfiltration filtration: 7500Kg of fermented broth (solid content of fermentation broth: 3.7%) fermented by Cordyceps is filtered by microfiltration to obtain 6374Kg of microfiltration dialyzate of Cordyceps and 1126Kg of wet mycelium (water content is 77%) ), the light transmittance of the dialysate is 80%, and the wet mycelium can be directly dried and pulverized at low temperature to obtain fermented Cordyceps fungus powder. The membrane material used for microfiltration is a ceramic membrane with a pore size of 500nm. The specific process conditions are: the operating temperature is 50-60°C, the inlet pressure is 2.3bar, the outlet pressure is 0.9bar, and the pressure difference is 1.4bar.

[0040] 2, ultrafiltration filtration: the microfiltration dialysate 6374Kg obtained in step 1 is filtered by ultrafiltration to obtain ultrafiltration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com