Modified diamond abrasive tool and manufacturing method thereof

A production method and diamond technology, applied in the direction of grinding/polishing hand tools, manufacturing tools, metal processing equipment, etc., can solve the problems of increasing the contact area, disguised waste, shortening tool life, etc., to reduce the contact area, prolong the The effect of high service life and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

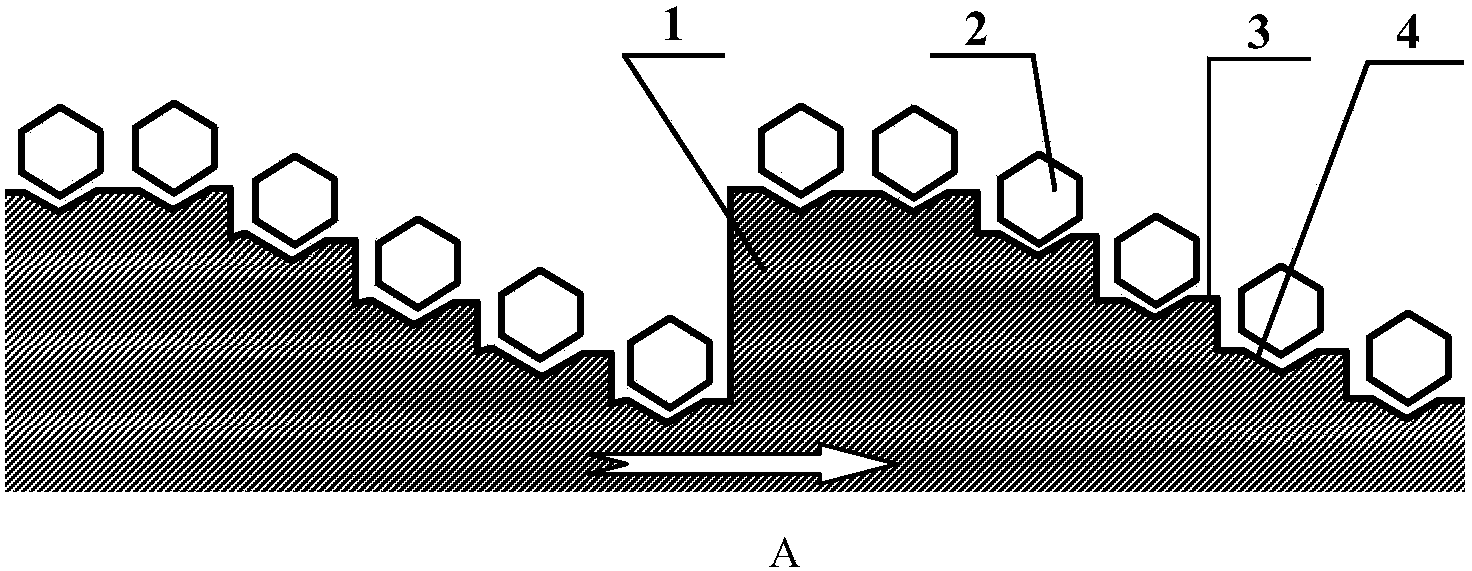

[0036] Such as Figure 1~5 Shown, be a kind of improved diamond abrasive tool of the present invention, comprise substrate and be arranged on the diamond abrasive material 2 of the working zone of substrate surface, the working zone of substrate surface is toothed surface, in the present embodiment, Figure 2-5 It is shown as two teeth 1, and each tooth 1 is composed of two planes, one of which is a vertical plane, and several steps 3 are provided on the other plane, thus forming a stepped plane. Each step 3 is composed of a vertical surface and a horizontal surface. The step surface is lowered step by step from the working direction A. At least one installation groove 4 for accommodating the lower part of the diamond abrasive is opened on the horizontal surface of each step. The diamond abrasive 2 is formed by brazing. Welding agent 5 is brazed and fixed in the installation groove 4 and arranged in an orderly manner on the step surface, the highest end of the diamond abrasive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com