Tobacco sheet containing tea flower extractive and preparation method thereof

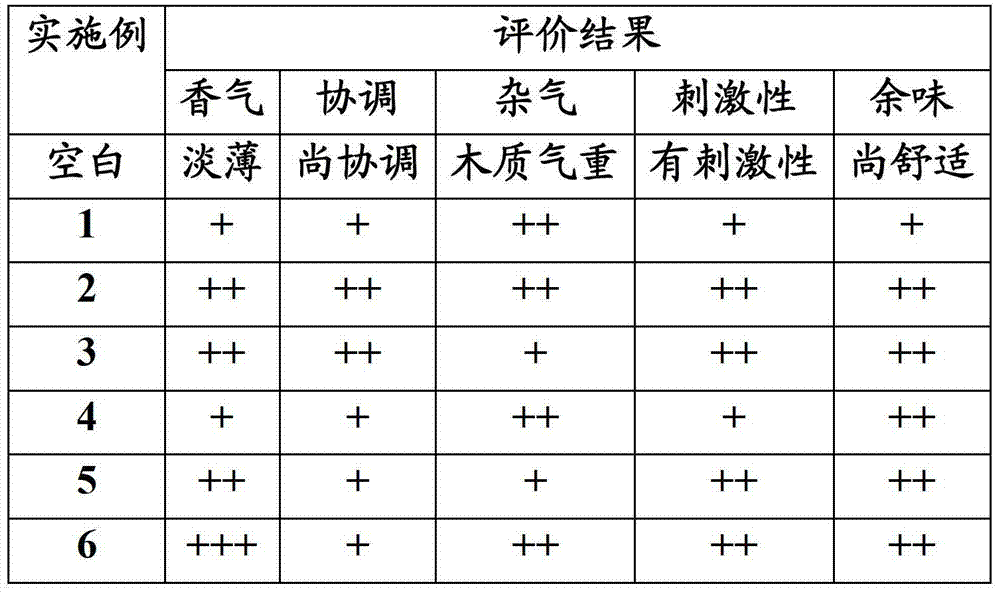

A technology of tea tree flower extract and tobacco sheet, which is applied in the directions of tobacco, tobacco preparation, tobacco processing, etc., can solve the problems such as no tea tree flower tobacco sheet, lack of tobacco aroma, prominent woodiness and pungency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0113] The tea tree flowers are picked from the Tieguanyin tea tree in Anxi, Fujian, and dried naturally outside for 1-2 days after picking.

[0114] The tea tree flower is sent to the mixing tank together with the tobacco material at a ratio of 1% (weight percentage), add water and stir evenly, and then send it to the fiber thinning machine, so that the fiber is loosened to make a coarse pulp and then sent to the mixing tank. Under continuous stirring, wood pulp fibers are added, ground and beaten to make pulp. The pulp is formed into a film base through papermaking and drying processes; the coating concentrate is directly coated on the film base, and the film base is dried to obtain a tobacco sheet containing tea tree flower flavor.

Embodiment 2

[0116] The tea tree flowers are collected from the Wuyi rock tea tree in Wuyi Mountain, Fujian Province, and are naturally dried outdoors for 1-2 days after picking.

[0117] The tea tree flower is sent to the mixing tank together with the tobacco material at a ratio of 3% by weight, and the mixture is added with water and stirred evenly, and then sent to the fiber thinning machine, so that the fiber is decomposed and made into a coarse pulp, and then sent to the mixing tank. Under continuous stirring, wood pulp fibers are added, ground and beaten to make pulp. The pulp is formed into a film base through papermaking and drying processes; the coating concentrate is directly coated on the film base, and the film base is dried to obtain a tobacco sheet containing tea tree flower flavor.

Embodiment 3

[0119] The tea tree flowers are picked from Pu'er tea trees in Yunnan, and are naturally dried outdoors for 1-2 days after picking.

[0120] The tea tree flower is sent to the mixing tank together with the tobacco material in the proportion of 5% by weight, and the water is added to stir evenly, and then sent to the fiber thinning machine, so that the fiber is loosened and made into a coarse pulp, and then sent to the mixing tank. Under continuous stirring, wood pulp fibers are added, ground and beaten to make pulp. The pulp is formed into a film base through papermaking and drying processes; the coating concentrate is directly coated on the film base, and the film base is dried to obtain a tobacco sheet containing tea tree flower flavor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com