High-purity rice bran protein and rice bran fibers and preparation method thereof

A technology of rice bran protein and rice bran fiber, which is applied to the preparation of high-purity rice bran protein and rice bran fiber, and the field of high-purity rice bran protein and rice bran fiber, can solve the problems of poor smell and flavor of residue, not getting enough attention, and being difficult to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

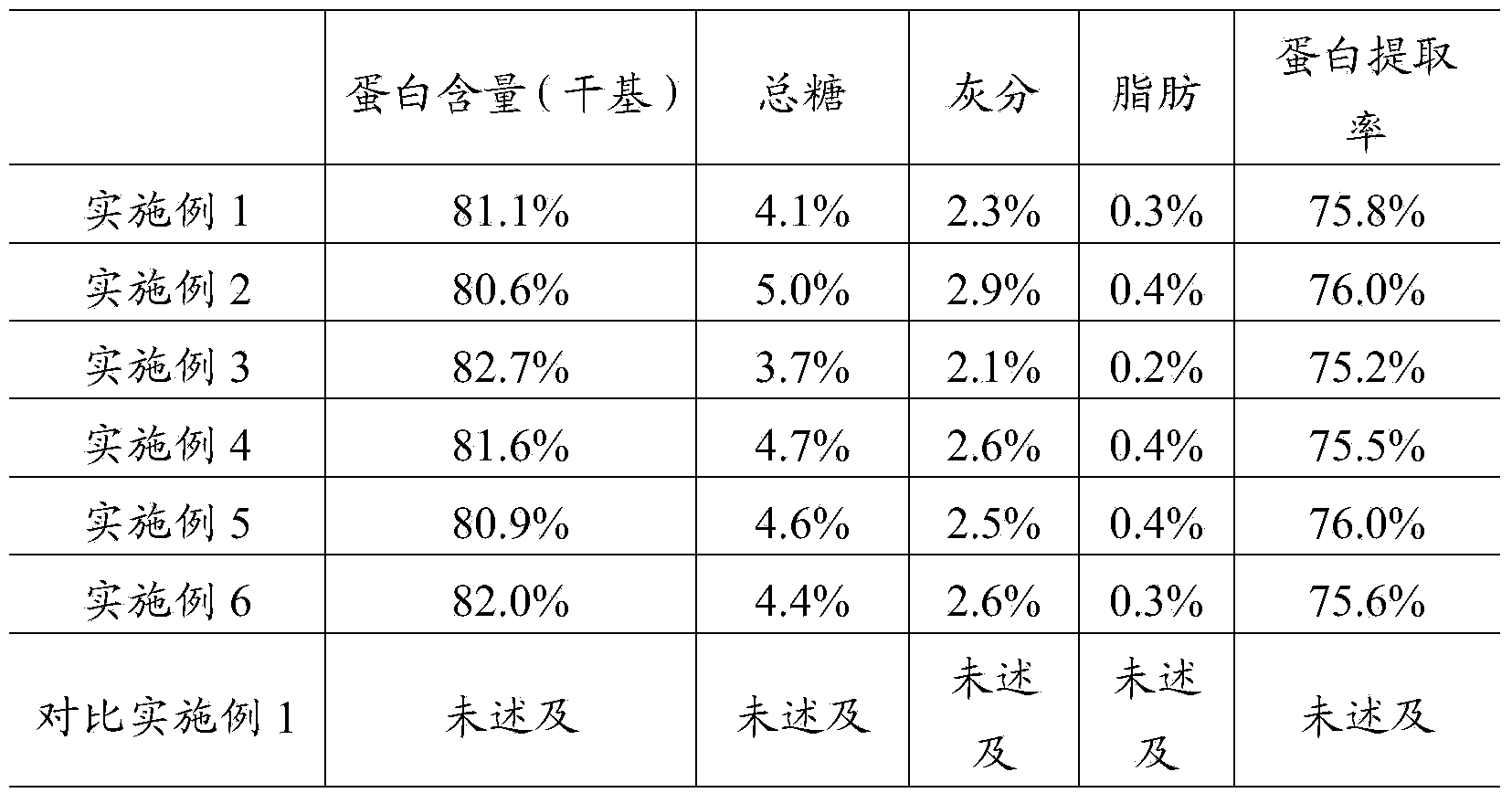

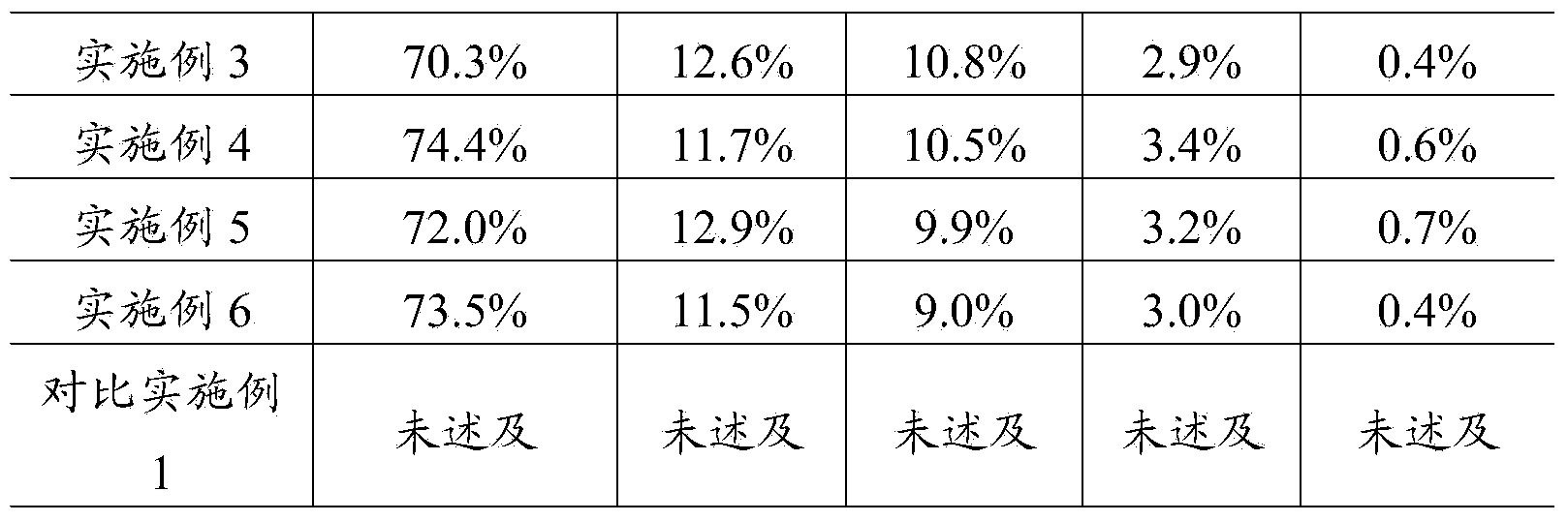

Embodiment 1

[0093] Embodiment 1: Preparation of high-purity rice bran protein and rice bran fiber

[0094] The implementation steps of this embodiment are as follows:

[0095] A. Raw material pretreatment

[0096] Using the screening method, 2000 kg of defatted rice bran raw materials sold by Jiangxi Jinnong Rice Industry Co., Ltd. (based on the total weight of defatted rice bran raw materials, protein content 18.1%, ash content 13.9%, fat 0.95%, total sugar 30.6%, crude fiber 25.7% ) to remove the tangible foreign matter present in the mixture; then, the sieved defatted rice bran raw material was crushed to a particle size of 120 mesh using a crushing equipment sold by Jiangyin Weida Pharmaceutical Machinery Manufacturing Co., Ltd. to obtain defatted rice bran powder;

[0097] B. The first pulping and enzyme reaction

[0098] Add water to the defatted rice bran powder obtained in step A to adjust the slurry to obtain a feed liquid with a defatted rice bran powder concentration of 20% b...

Embodiment 2

[0108] Embodiment 2: Preparation of high-purity rice bran protein and rice bran fiber

[0109] The implementation steps of this embodiment are as follows:

[0110] A. Raw material pretreatment

[0111] Using the sieving method, 2000 kg of defatted rice bran raw materials sold by Jiangxi Hehe Industrial Co., Ltd. (based on the total weight of defatted rice bran raw materials, protein content 19.4%, ash content 12.0%, fat 0.9%, total sugar 32.1%, crude fiber 27.8 %) to remove the tangible foreign matter present; then, the sieved defatted rice bran raw material is sold by Jiangyin Weida Pharmaceutical Machinery Manufacturing Co., Ltd., Jiangyin Haike Powder Equipment Manufacturing Co., Ltd., and Jiangyin Longchang Machinery Manufacturing Co., Ltd. Advanced crushing equipment is crushed to a particle fineness of 150 mesh to obtain defatted rice bran powder;

[0112] B. The first pulping and enzyme reaction

[0113] Add water to the defatted rice bran powder obtained in step A t...

Embodiment 3

[0123] Embodiment 3: Preparation of high-purity rice bran protein and rice bran fiber

[0124] The implementation steps of this embodiment are as follows:

[0125] A. Raw material pretreatment

[0126] Using the screening method, 2000 kg of defatted rice bran raw materials sold by Yutai County Baofeng Oil Co., Ltd. (based on the total weight of defatted rice bran raw materials, protein content 16.1%, ash content 11.2%, fat 0.75%, total sugar 37.2%, crude fiber 24.3 ) to remove the tangible foreign matter existing in it; then, the sieved defatted rice bran raw material is sold by Jiangyin Weida Pharmaceutical Machinery Manufacturing Co., Ltd., Jiangyin Haike Powder Equipment Manufacturing Co., Ltd., and Jiangyin Longchang Machinery Manufacturing Co., Ltd. The crushing equipment is crushed to a particle fineness of 120 mesh to obtain defatted rice bran powder;

[0127] B. The first pulping and enzyme reaction

[0128] Add water to the defatted rice bran powder obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com