Method for preparing er-doped silicon carbide optical waveguide through ion implantation

A silicon carbide optical and ion implantation technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of low activation efficiency, secondary defects, and restrictions on erbium-doped silicon carbide optical waveguides, so as to avoid low waveguide gain and improve Effects of light gain and enhancement of fluorescence luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

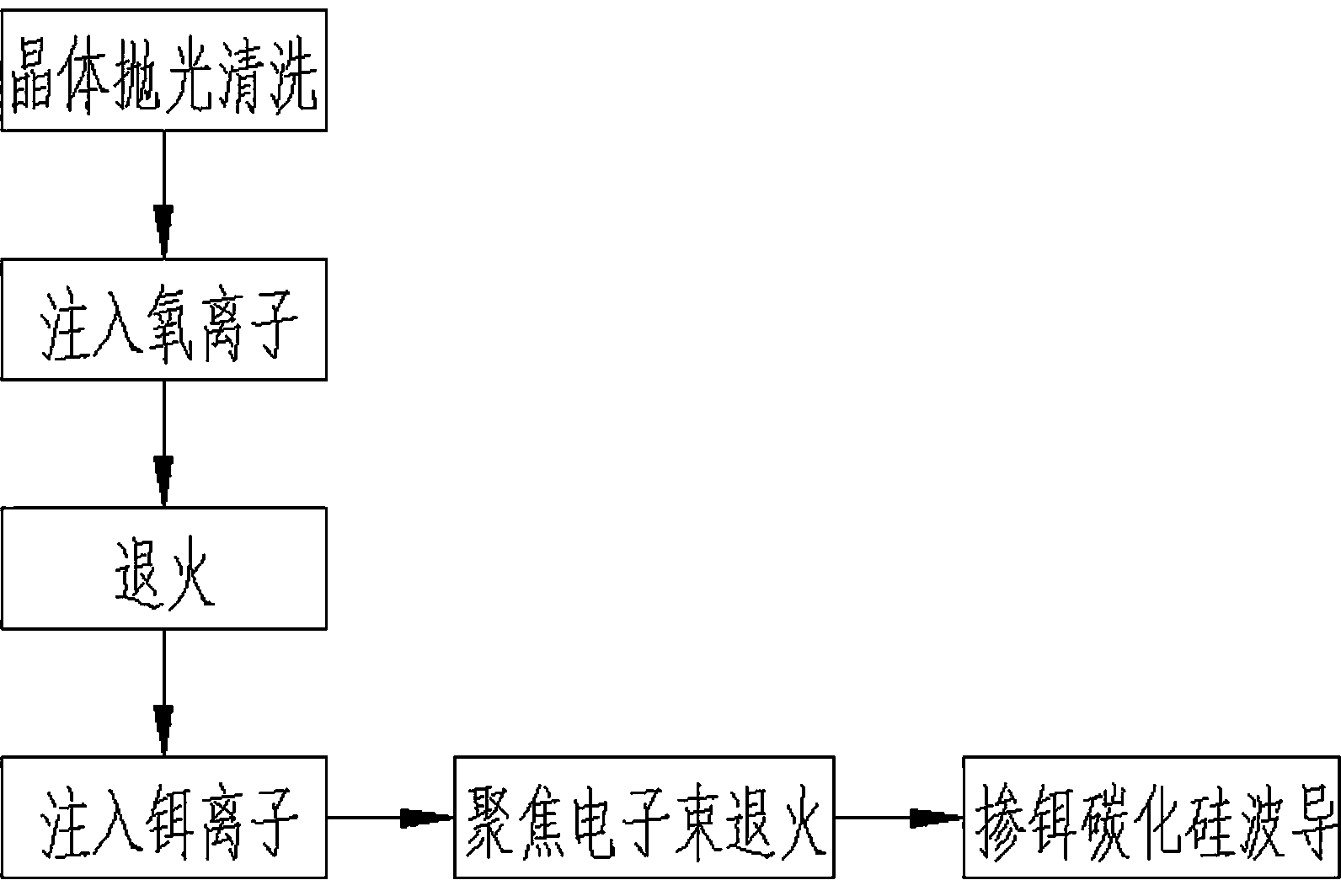

[0028] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0029] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 0.5MeV, and the injection dose is 1×10 ions / cm , the whole process is carried out at a temperature of 600°C.

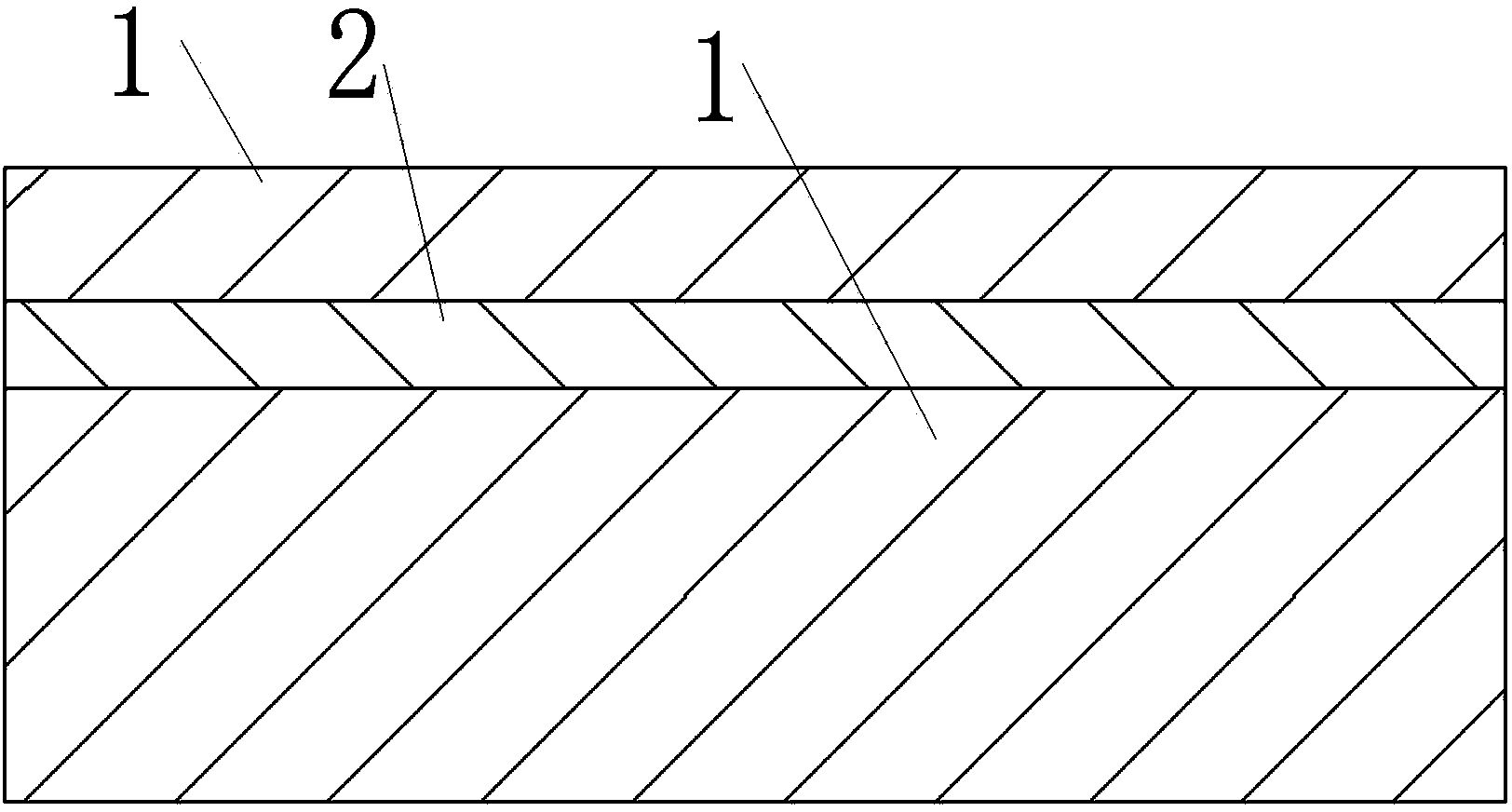

[0030] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200°C, and the annealing time is 0.5h. Through this process, a silicon dioxide buried layer 2 with a thickness of approximately 600 nm and a near-stoichiometric ratio can be obtained on the silicon carbide sample.

[0031] (4) Place the sample obtained in (3) in the target chamber of the accelerato...

Embodiment 2

[0036] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0037] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 1MeV, and the injection dose is 2.5×10 ions / cm , the whole process is carried out at a temperature of 650°C.

[0038] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200° C., and the annealing time is 1 h. A nearly stoichiometric silicon dioxide buried layer 2 with a thickness of about 970 nm can be obtained on the silicon carbide sample through this process.

[0039] (4) Place the sample obtained in (3) in the target chamber of the accelerator, and evacuate to...

Embodiment 3

[0043] (1) The silicon carbide sample 1 that has been cut and optically polished is cleaned with acetone and ultrasonic waves, and then the cleaned silicon carbide sample 1 is cleaned.

[0044] (2) Put the sample cleaned in (1) in the target chamber of the accelerator, and evacuate to 1×10 Pa, the implantation process of oxygen ions is performed. The injection energy is 2.0MeV, and the injection dose is 2.5×10 ions / cm , the whole process is carried out at a temperature of 650°C.

[0045] (3) Place the sample obtained in (2) in an annealing furnace, and perform high-temperature annealing treatment on the sample in an argon atmosphere. The annealing temperature is controlled at 1200° C., and the annealing time is 1 h. Through this process, a silicon dioxide buried layer 2 with a thickness of approximately 600 nm and a near-stoichiometric ratio can be obtained on the silicon carbide sample.

[0046] (4) Place the sample obtained in (3) in the target chamber of the acceler...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com