High-strength martensite ferrite two-phase stainless steel anti-corrosion oil casing pipe and manufacturing method thereof

A technology of duplex stainless steel and manufacturing method, applied in the field of oil casing, can solve the problems of high alloy content, difficult to meet the requirements of deep wells, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

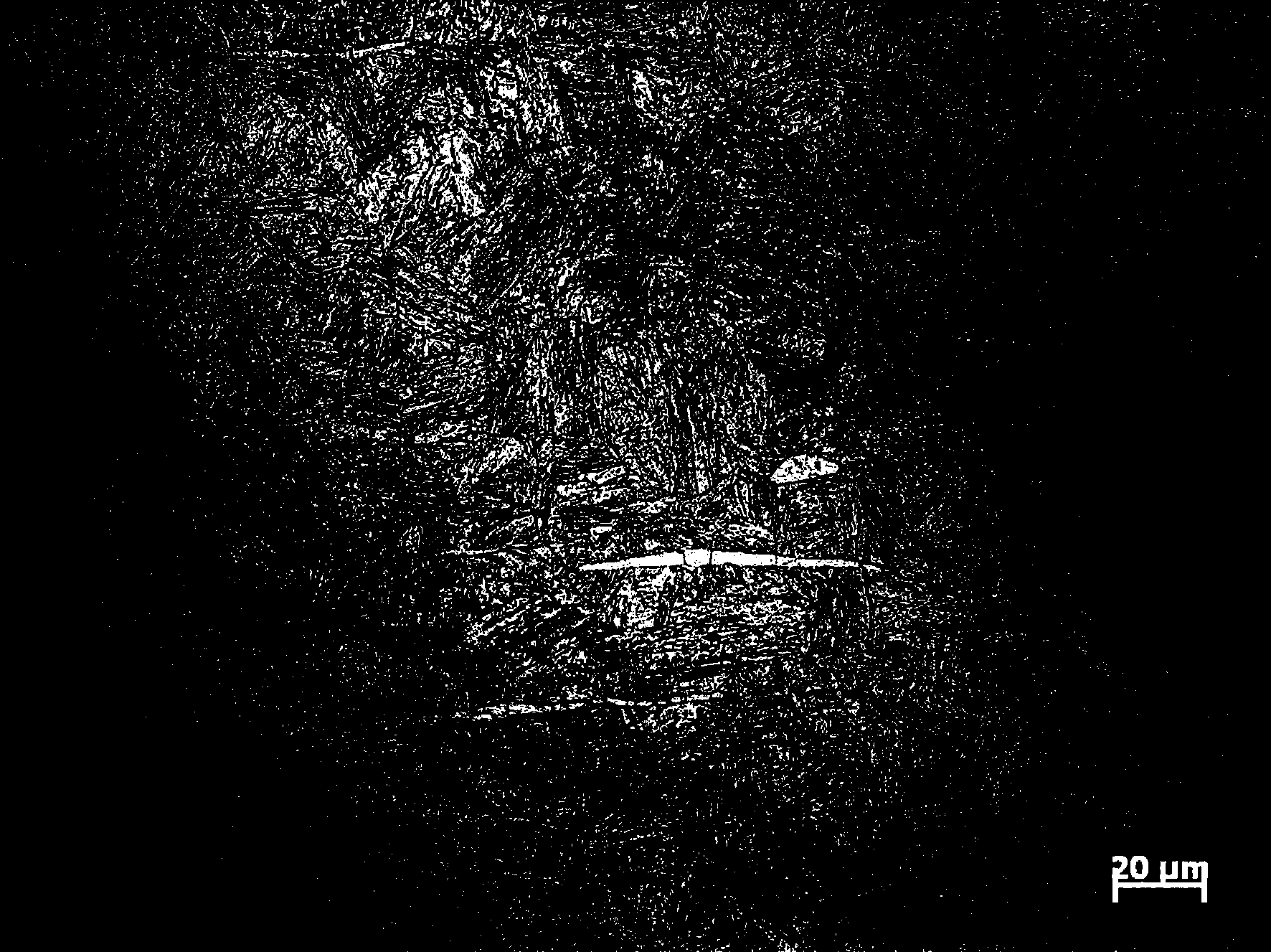

Image

Examples

Embodiment Construction

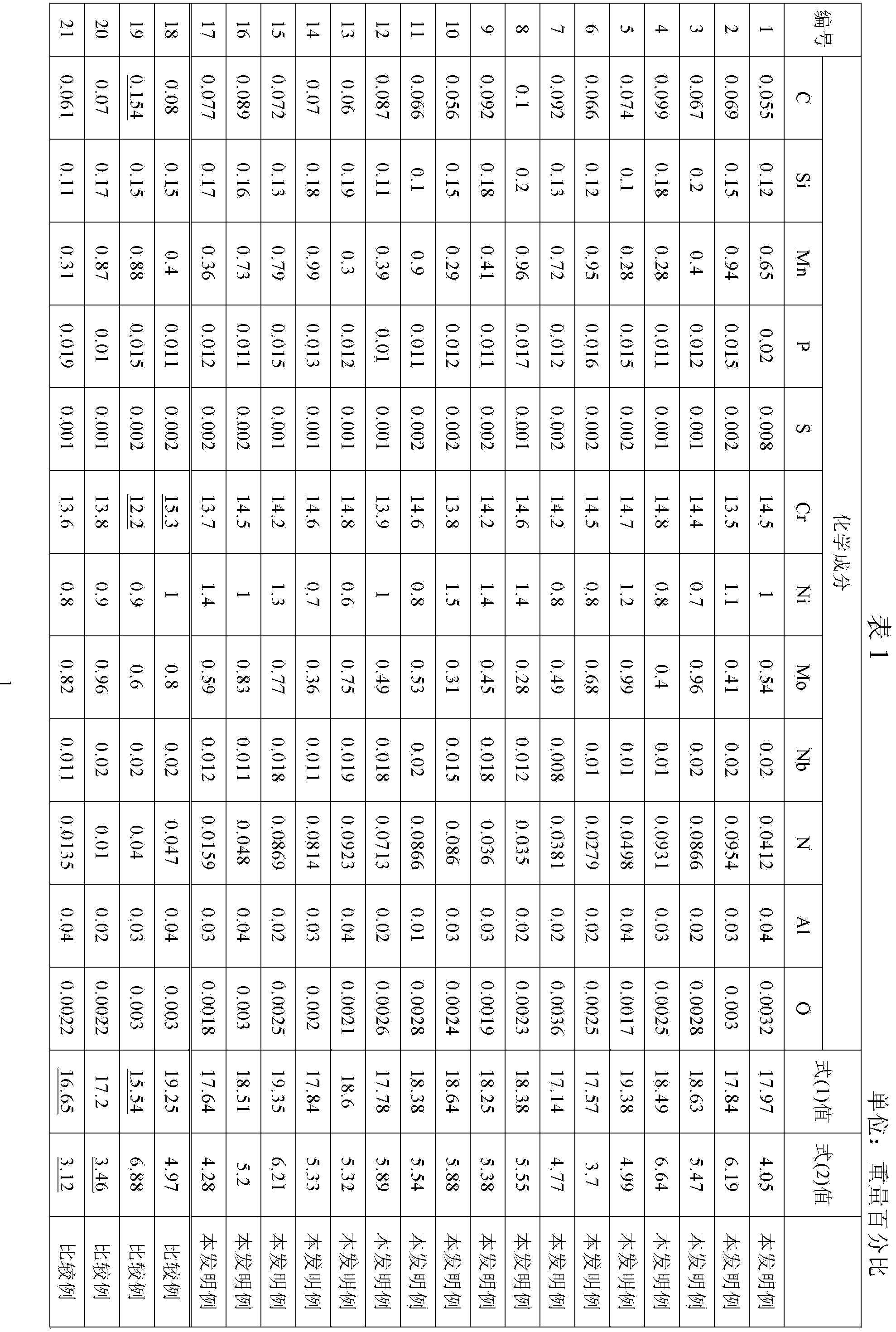

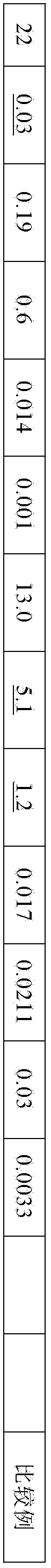

[0051] The present invention will be further described below by embodiment.

[0052] After the molten steel with the chemical composition in Table 1 was cast into a round ingot, it was pierced and rolled into a steel pipe by a small rolling mill, and then air-cooled to make a seamless steel pipe with an outer diameter of 73.02mm×a wall thickness of 7.01mm.

[0053] The values of formula (1) and formula (2) listed in Table 1 are calculated according to the following two formulas respectively:

[0054] Cr+1.5Mo+2Ni+16N (1)

[0055] Ni+30(C+N)+8Nb (2)

[0056] Among them, Cr, Mo, Ni, N, C, Nb, etc. are mass %.

[0057] After heating the above seamless steel pipe at 950°C for 30 minutes and air cooling to room temperature, temper at the temperature in Table 2, holding time for 60 minutes, and air cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com