Wafer-processing tape and method for manufacturing semiconductor device using same

A technology of wafer processing and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, film/sheet-like adhesives, etc. It can solve the problems that the adhesive layer cannot be cut and the chip cannot be peeled off, and the peeling force can be achieved. The effect of adequate, good pickup performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0188] With respect to 100 parts by mass of the acrylic copolymer (a-1), 5 parts by mass of CORONATE L (manufactured by Japan Polyurethane Co., Ltd.) was added as polyisocyanate, and 3 parts by mass of IRGACURE-184 (manufactured by Japan Ciba-Geigy Co., Ltd.) was added as photopolymerization initiator, the mixture was dissolved in ethyl acetate and stirred to prepare an adhesive composition.

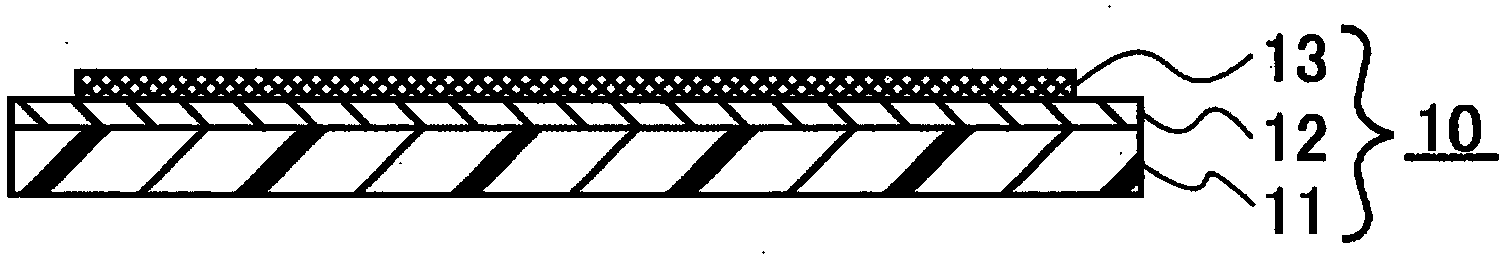

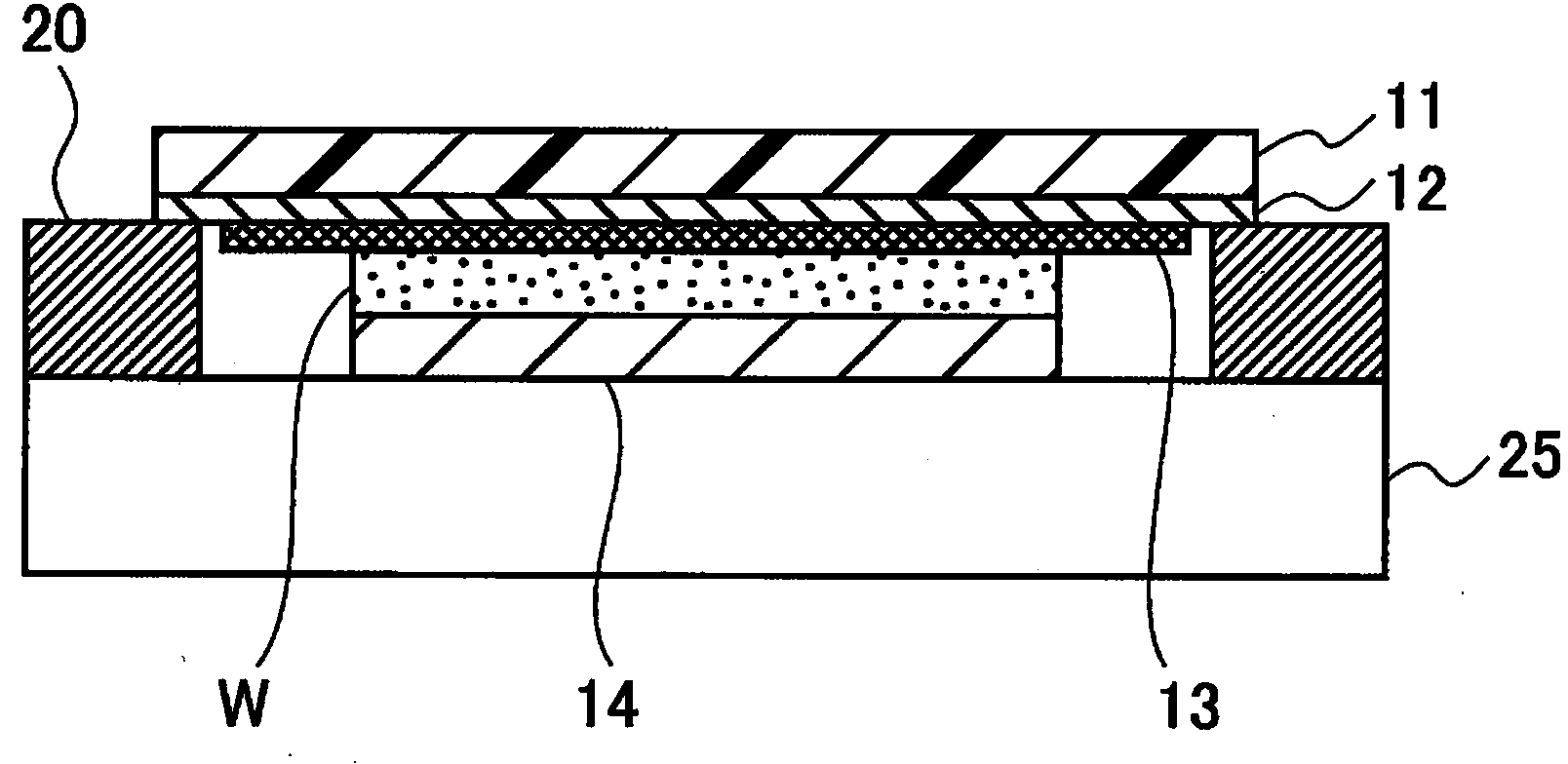

[0189] Next, the pressure-sensitive adhesive composition was coated on a release liner made of a polyethylene terephthalate film subjected to mold release so that the thickness after drying was 10 μm, and dried at 110° C. for 3 minutes. After that, it was bonded to the base film to produce a PSA sheet in which the PSA layer was formed on the base film.

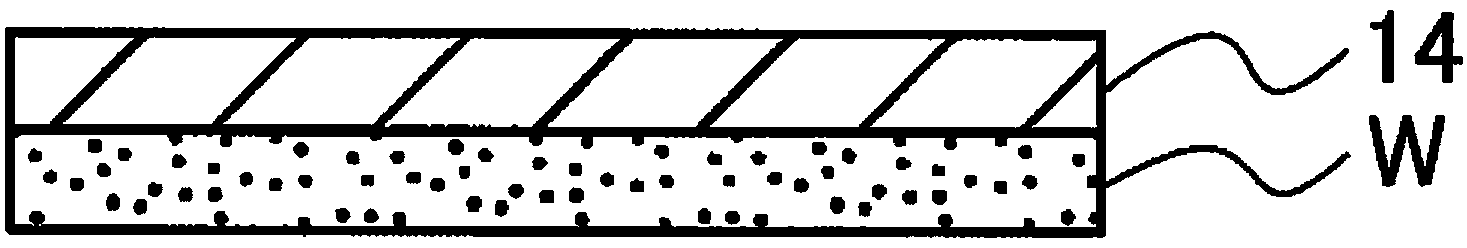

[0190] Next, the adhesive composition (d-1) was coated on a release liner made of a release-treated polyethylene terephthalate film so that the thickness after drying was 20 μm. Drying was carried out for 5 minutes to prepare an adhesiv...

Embodiment 2

[0193] Except having used the acrylic-type copolymer (a-2), it carried out similarly to Example 1, and prepared the adhesive composition. Using this adhesive composition, by the method similar to Example 1, the tape for wafer processing was produced.

Embodiment 3

[0195] Except having used the acrylic-type copolymer (a-3), it carried out similarly to Example 1, and prepared the adhesive composition. Using this adhesive composition, by the method similar to Example 1, the tape for wafer processing was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com