Method for producing haematochrome by using Bacillus subtilis

A technology of Bacillus subtilis and red pigment, which is applied in the field of purification and refinement of crude red pigment products, can solve the problems of large demand and waste of raw materials, and achieve the effects of high pigment yield, easy operation and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

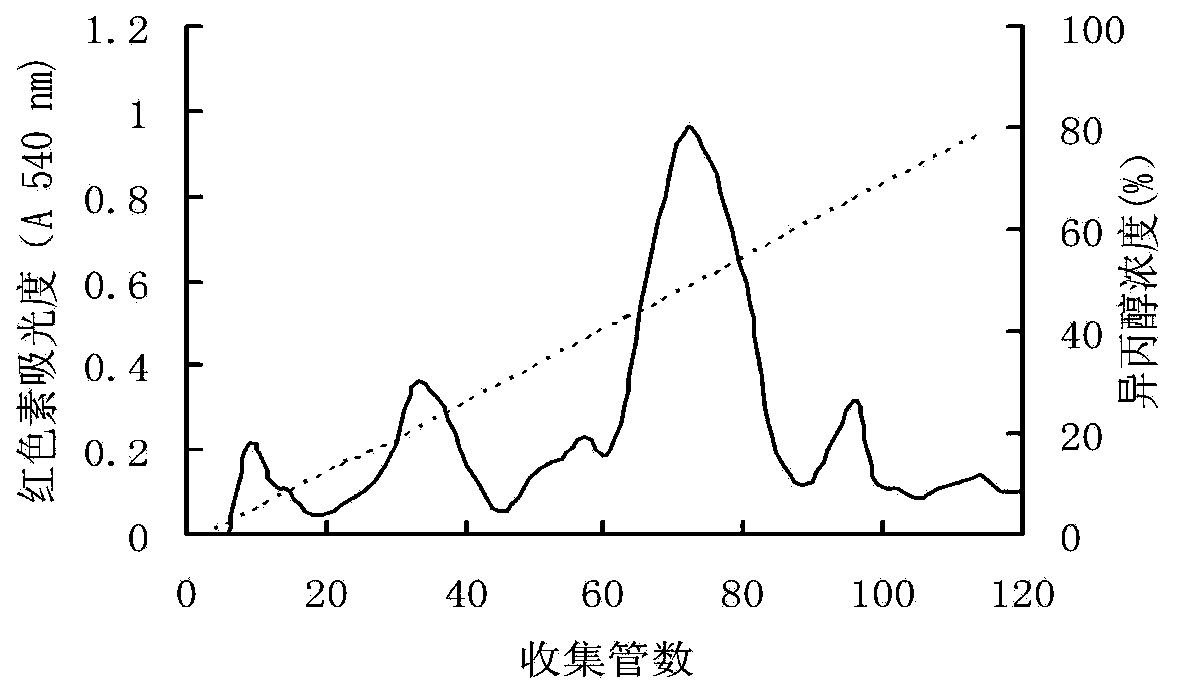

Image

Examples

Embodiment 1

[0034] Embodiment 1: Screening of high-yield red pigment strains

[0035] (1) Enrichment culture:

[0036]Put 1g of soil sample (collected in humus-rich soil) into a 250ml Erlenmeyer flask filled with 80ml of sterile water, add sterile glass beads, and vibrate in a shaker at 150r / min for 20min. Take 3-4ml of the shaken emulsion, add it into 100ml enrichment medium, and place it in a constant temperature shaker at 35°C with a rotation speed of 170r / min for 48h. Enrichment medium: 5ml bran extract, 0.3g beef extract, 1g peptone, 0.5g NaCl, K 2 HPO 4 0.1g, MgSO 4 ·7H 2 O0.02g, H 2 O95mL, pH7.2, sterilized at 121°C for 20min.

[0037] (2) Primary screening:

[0038] The enriched culture solution was diluted stepwise to 10 -4 、10 -5 、10 -6 , take 0.2ml and spread it on the primary screening solid medium plate, and when the plate is air-dried until there is no flowing liquid on the surface, cultivate it in a constant temperature incubator at 32-37°C for 30-36 hours, then l...

Embodiment 2

[0050] Example 2: Morphological characteristics and physiological and biochemical characteristics of high-yield red pigment strain HJ

[0051] Bacterial strain described in the present invention, after beef extract peptone culture medium plate culture 18h, observe bacterial colony shape, surface is rougher, edge is not neat, and bacterial colony color is light red, and Gram's staining is positive. The shape of the bacteria is short rod rod. The cell size is 0.65μm×2.7μm, can form endophytic spores, and the cell has motility; the cellulolysis test is negative; in the sugar fermentation experiment, the strain can use soluble starch, glucose, maltose and sucrose as the only In other physiological and biochemical tests, the strain was positive for contact enzymes and VP assays, could hydrolyze starch, liquefy gelatin, and utilize citrate without producing fluorescent pigments, and the methyl red test was positive. The specific morphological, physiological and biochemical characte...

Embodiment 3

[0055] Embodiment 3: Shake flask fermentation method produces red pigment

[0056] 1. Preparation of fermentation strains: Streak the pre-screened and preserved Bacillus subtilis strains on the beef extract peptone medium plate, and then place them upside down in a constant temperature incubator at 37°C for 15-24 hours for activation.

[0057] The configuration method of the solid medium is: beef extract 0.3g, peptone 1.0g, agar powder 1.5g, add distilled water to 100mL, pH7.2, 121°C, sterilize for 20min.

[0058] 2. Prepare the seed solution of Bacillus subtilis: pick a single colony from the activated strain in step 1, insert it into a 250mL Erlenmeyer flask with 30mL seed medium, and culture it on a shaker at 35-37°C for 18-25h , speed 160-200r / min.

[0059] The composition of the seed medium: peptone 1g, beef extract 0.5g, yeast powder 0.5g, NaCl 0.5g, K 2 HPO 4 0.02g, add distilled water to 100ml, pH6.8-7.2, sterilize at 121°C for 20min.

[0060] 3. Shake flask fermen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com