Plate with-temperature mixed-acid pickling process used for stainless steel plate

A technology for stainless steel plates and strips, applied in the direction of manufacturing tools, metal processing equipment, workpiece surface treatment equipment, etc., can solve the problems of reducing the temperature of stainless steel plates, improve production efficiency, save passivation treatment procedures, and pickling time The effect of shortening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

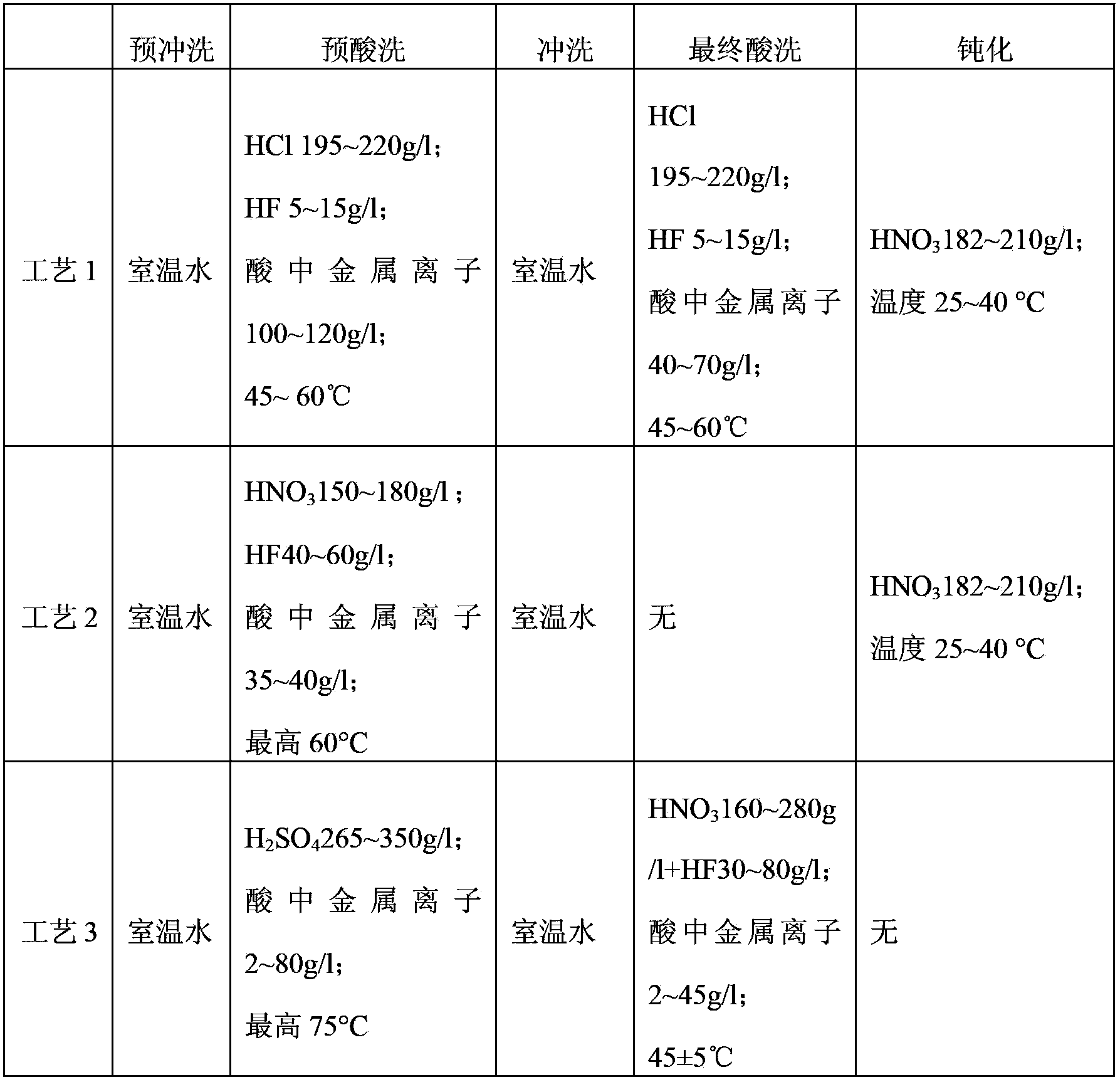

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Pickling of 304 hot-rolled stainless steel plates

[0035] The thickness of the steel plate is 9mm, the width is 1900mm, and the length is 6000mm.

[0036] The surface of the hot-rolled stainless steel plate is subjected to shot blasting treatment, and then the hot-rolled stainless steel plate is sent to the pre-washing section (hood) through the roller table. After emptying, the running speed of the hot-rolled stainless steel plate is kept at 4.5m / min; After the washing section (hood), it enters the final pickling section (hood) for pickling. The acid composition is: HNO 3 288g / l, HF 38g / l, metal ion content in acid 38g / l, temperature 40°C, running speed of hot-rolled stainless steel plate kept at 4.5m / min; Final cleaning, air curtain blowing, drying, and pickling are completed.

Embodiment 2

[0037] Embodiment 2: Pickling of 316L hot-rolled stainless steel plate

[0038] The thickness of the steel plate is 22mm, the width is 1900mm, and the length is 6800mm.

[0039] The surface of the hot-rolled stainless steel plate is subjected to shot blasting treatment, and then the hot-rolled stainless steel plate is sent to the pre-washing section (hood) through the roller table. After emptying, the running speed of the hot-rolled stainless steel plate is kept at 4.0m / min; After the washing section (hood), it enters the final pickling section (hood) for pickling. The acid composition is: HNO 3 268g / l, HF 45g / l, metal ion content in acid 36g / l, temperature 45°C, running speed of hot-rolled stainless steel plate kept at 4.0m / min; Final cleaning, air curtain blowing, drying, and pickling are completed.

Embodiment 3

[0040] Embodiment 3: Pickling of S31803 hot-rolled stainless steel plate

[0041] The thickness of the steel plate is 30mm, the width is 1800mm, and the length is 5800mm.

[0042] The surface of the hot-rolled stainless steel plate is subjected to shot blasting treatment, and then the hot-rolled stainless steel plate is sent to the pre-washing section (hood) through the roller table. The acid composition is: HNO 3 228g / l, HF86g / l, metal ion content in acid 36g / l, temperature 45°C, running speed of hot-rolled stainless steel plate kept at 0.6m / min; In the washing section (hood), the water temperature is 55~65°C; after the hot-rolled stainless steel plate exits the washing section (hood), it enters the final pickling section (hood) for pickling. The acid composition is: HNO 3 298g / l, HF 40g / l, metal ion content in acid 39g / l, temperature 40°C, running speed of hot-rolled stainless steel plate kept at 0.6m / min; after the hot-rolled stainless steel plate leaves the final picklin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com