Sandwich-type microreactor and application thereof in enzymatic synthesis of caffeic acid phenethyl ester

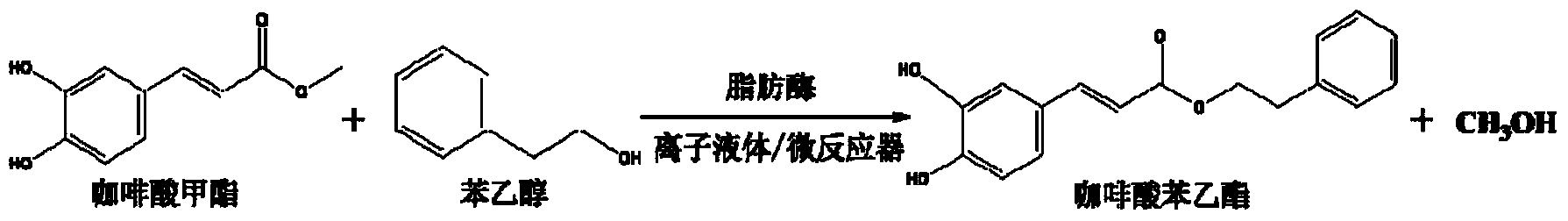

A technology of phenethyl caffeate and microreactor, which is applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve the problem of unreported phenethyl caffeate and reactor volume Large, complex product components and other issues, to achieve good industrial application prospects, enhance mass transfer, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

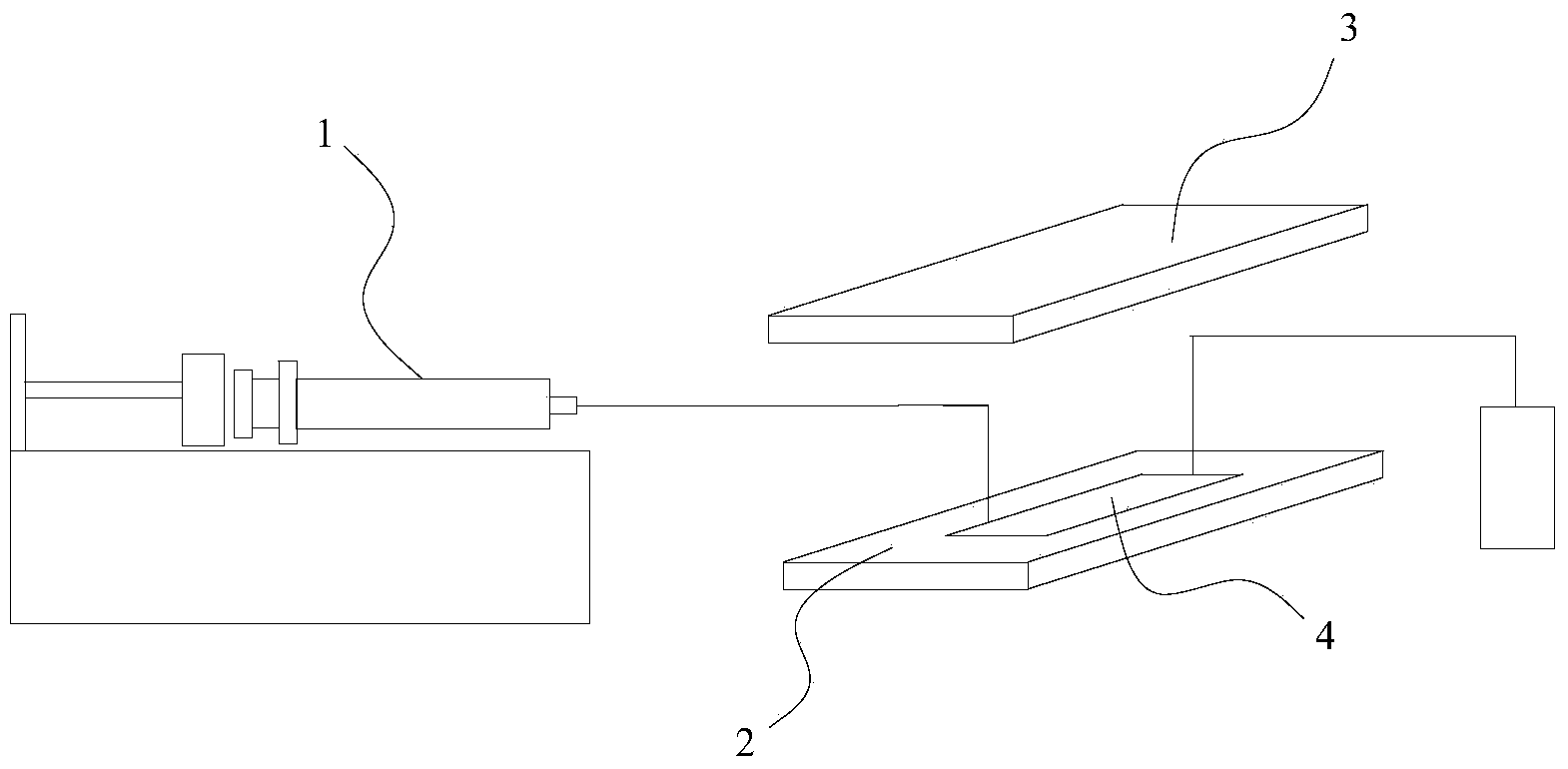

[0032]A sandwich microreactor, including a syringe pump 1 and a reactor body, the material of the reactor body is polydimethylsiloxane (polydimethylsiloxane), and is composed of a reaction plate 2 and a cover plate 3. load area 4. A fixing clip is arranged between the reaction plate and the cover plate.

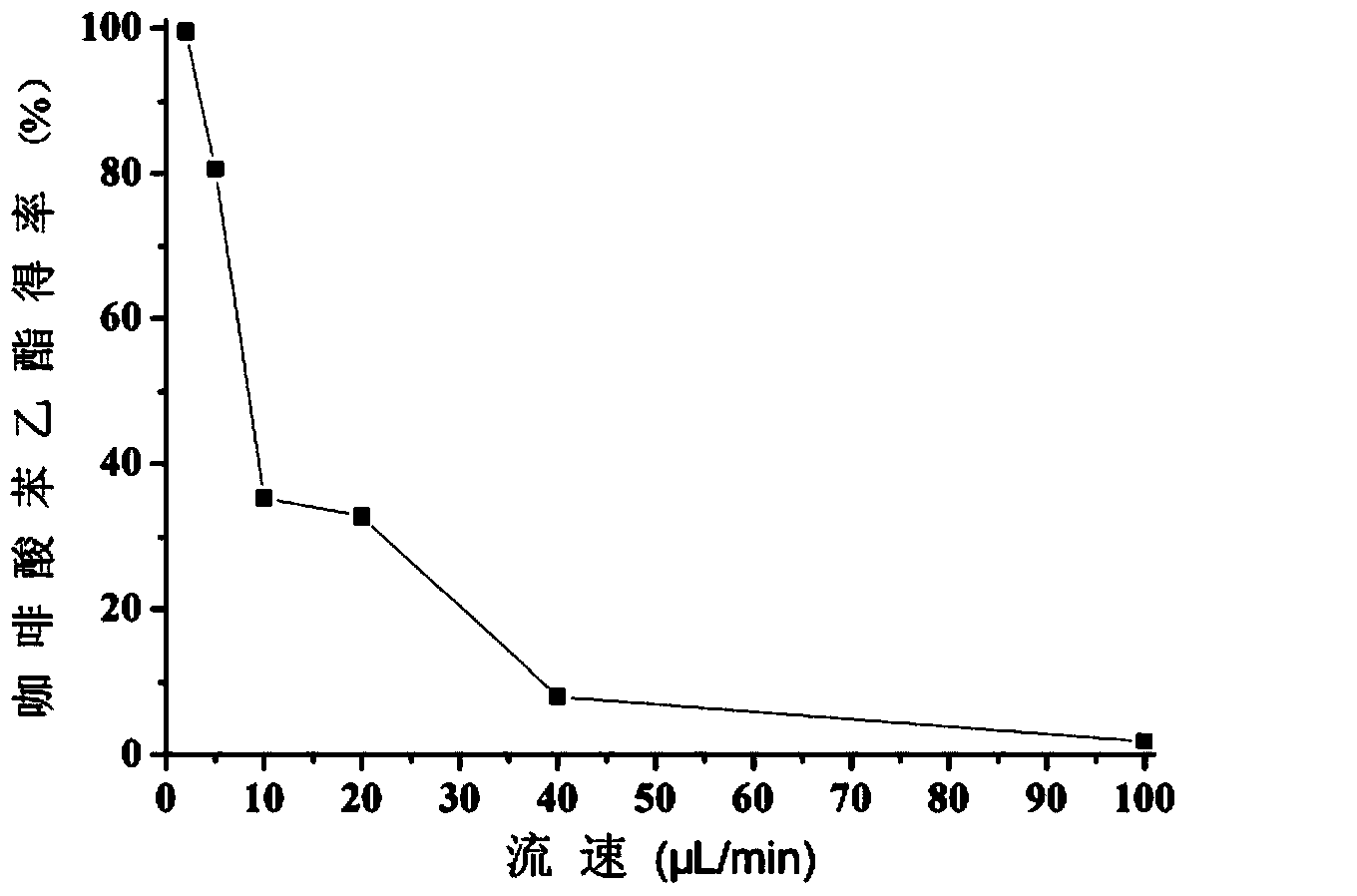

[0033] The dimensions of the immobilized area were 1 cm wide, 500 μm deep, and 50 mm long, and Novozym 435 (60 mg) was filled into the microchannel. Dissolve 0.1 mg of methyl caffeate in 1 mL of [Hmim][PF 6 ] In the ionic liquid, a reaction system was formed according to the molar ratio of methyl caffeate and phenylethyl alcohol at 1:1. The prepared reaction system was injected into the microreactor through a micro-injection pump at a flow rate of 100 μL / min (retention time of 3 min), and the temperature was controlled at 30°C. The export material was collected, and the yield of phenethyl caffeate synthesized by enzymatic transesterification was detected by HPLC to be 1.5%...

Embodiment 2

[0035] The structure of the device was as in Example 1, wherein the size of the immobilized region was 1 cm wide, 500 μm deep, and 200 mm long, and Novozym435 (240 mg) was filled into the microchannel. Take 40 mg of methyl caffeate and dissolve it in 1 mL of [Omim][Cl] ionic liquid, and form a reaction system according to the molar ratio of methyl caffeate to phenylethyl alcohol of 1:100. The prepared reaction system was injected into the microreactor through a microsyringe pump at a flow rate of 2 μL / min (retention time of 2.5 h), and the temperature was controlled at 80° C. The export material was collected, and the yield of caffeic acid phenethyl ester by enzymatic transesterification was detected by HPLC to be 21.3%.

Embodiment 3

[0037] The structure of the device was as in Example 1, wherein the size of the immobilized region was 1 cm wide, 500 μm deep, and 100 mm long, and Novozym435 (120 mg) was filled into the microchannel. Dissolve 10 mg of methyl caffeate in 1 mL of [TOMA][CF 3 SO 3 ] In the ionic liquid, the reaction system was formulated according to the molar ratio of methyl caffeate and phenylethyl alcohol of 1:50. The prepared reaction system was injected into the microreactor through a micro-injection pump, the flow rate was 20 μL / min (retention time was 15 min), and the temperature was controlled at 60°C. The export material was collected, and the yield of phenethyl caffeate synthesized by enzymatic transesterification was detected by HPLC as 32.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com