High-pressure reciprocating sealing gasket for pump valve and preparation method thereof

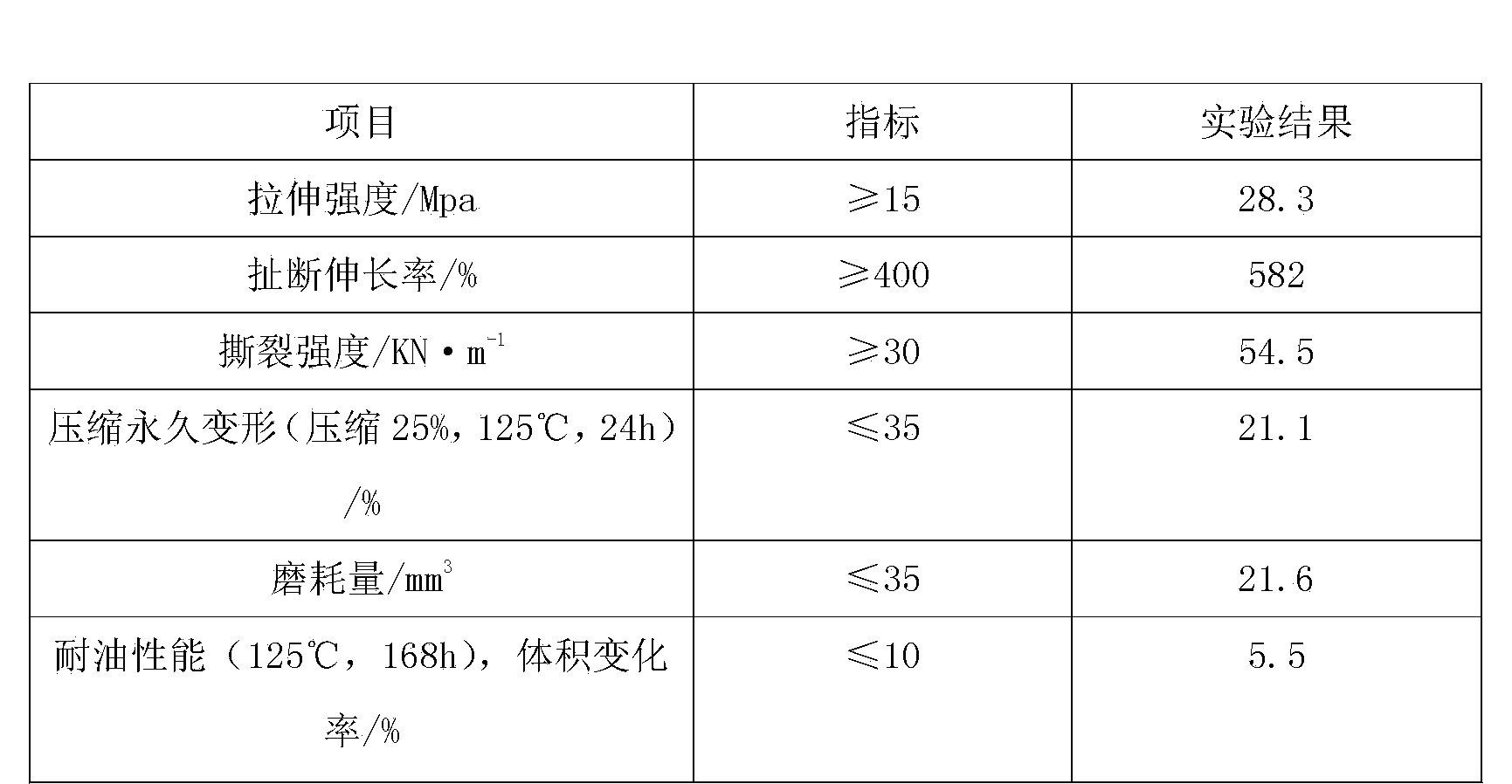

A sealing gasket and high-pressure technology, which is applied in the field of high-pressure reciprocating gaskets for pumps and valves and its preparation, can solve the problems of gasket compressive strength, impact resistance, service life, equipment use requirements, etc., and achieve good oil resistance, sealing Reliable, low compression set effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] A high-pressure reciprocating gasket for pump valves, made of the following raw materials (kg): nitrile rubber (P228) 80, EPDM rubber (Germany Lanxess 5962) 25, 3# smoked sheet rubber 20, SG -3 type PVC resin 12, sulfur 1.5, 1,4-bis-tert-butylperoxycumene 0.8, zinc oxide 1.5, stearic acid 2, modified nano-diamond 18, iron tailings powder 8, antioxidant MBZ 1.5, anti-aging agent RD 2, rhine wax 3, vaseline 4, fast extrusion carbon black N660 15, diethylene glycol dibenzoate 10, aluminum hydroxide 8, accelerator TMTD 1.5, accelerator NA-22 2.

[0013] The preparation method of described modified nano-diamond is as follows:

[0014] a. Weigh a certain amount of nano-diamond, add 4% nano-tantalum carbide, 3% nano-zirconia, 2% nano-magnesium nitride, 6% nano-attapulgite, 3% nano-barite and mix evenly , calcined at 430°C for 3h, cooled to room temperature, then added 1% tetraisopropylbis(dioctylphosphite acyloxy) titanate, 3% isooctyl palmitate, 5% polyisobutylene , 2% sod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com