Cold-resistant super-tough reinforced nylon 6 material for automobiles and preparation method thereof

A nylon and cold-resistant technology, which is applied in the field of polymer material modification, can solve problems such as difficulty in maintaining rigidity and poor interface compatibility, and achieve the effects of enhanced toughness, improved rigidity, and good cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

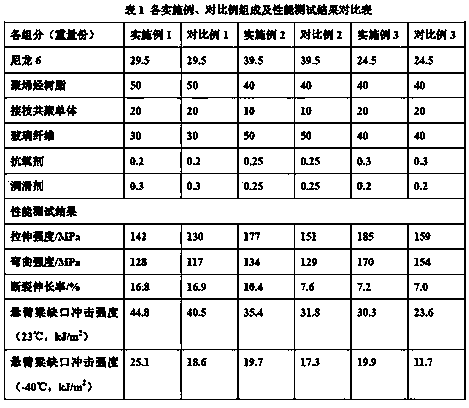

Examples

Embodiment 1

[0027] (1) Fully mix the polyolefin resin and grafted comonomer in the high mixer (stir in the high mixer for 6~10 minutes, the stirring speed is 200~800 rpm), send the mixed raw materials to Melt extrusion of twin-screw extruder. After 0.5~5 minutes of normal extrusion, add 7 strands of glass fiber (commercially available long glass fiber) into the side feed port of twin-screw extruder (accurately calculated according to the speed, 7 strands Exactly 30 parts by weight), the glass fiber is melted and blended with the melt, extruded and granulated, and dried to obtain the modified precursor; the extrusion process of the twin-screw extruder is: the screw speed is 300 rpm, each zone The heating temperature is: 140°C in the first zone, 150°C in the second zone, 165°C in the third zone, 175°C in the fourth zone, 175°C in the fifth zone, 180°C in the sixth zone, 190°C in the seventh zone, and 190°C in the eighth zone.

[0028] The composition of the modified precursor: 50 parts of p...

Embodiment 2

[0033] (1) Fully mix the polyolefin resin and grafted comonomer in the high mixer (stir in the high mixer for 6~10 minutes, the stirring speed is 200~800 rpm), send the mixed raw materials to Melt extrusion of twin-screw extruder. After 0.5~5 minutes of normal extrusion, add 10 strands of glass fiber (commercially available long glass fiber) into the side feeding port of twin-screw extruder (accurately calculated according to the speed, 10 strands Exactly 50 parts by weight), the glass fiber is extruded and granulated after being melted and blended with the melt, and dried to obtain the modified precursor; the extrusion process of the twin-screw extruder is: the screw speed is 350 rpm, each zone The heating temperature is: 140°C in the first zone, 145°C in the second zone, 160°C in the third zone, 170°C in the fourth zone, 170°C in the fifth zone, 175°C in the sixth zone, 180°C in the seventh zone, and 180°C in the eighth zone.

[0034] The composition of the modified precurso...

Embodiment 3

[0039] (1) Fully mix the polyolefin resin and grafted comonomer in the high mixer (stir in the high mixer for 6~10 minutes, the stirring speed is 200~800 rpm), send the mixed raw materials to The twin-screw extruder is melted (forming a toughened melt) and extruded. After 0.5 to 5 minutes of normal extrusion, add 9 strands of glass fiber (commercially available long glass fiber) into the side feed port of the twin-screw extruder ( Accurately calculated according to the rotational speed, 9 shares are just 40 parts by weight), the glass fiber is melted and blended with the melt, extruded and granulated, and dried to obtain the modified precursor; the extrusion process of the twin-screw extruder is: screw The speed is 360 rpm, and the heating temperature of each zone is: 150°C for zone 1, 160°C for zone 2, 180°C for zone 3, 190°C for zone 4, 200°C for zone 5, 220°C for zone 6, 210°C for zone 7, 210°C for zone 8 .

[0040] The composition of the modified precursor: 40 parts of po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com