Lead-free compact strontium postasium niobate textured ceramic and preparation method thereof

A technology of potassium strontium niobate and texture, applied in the field of lead-free ferroelectric ceramics, can solve problems such as environmental pollution, achieve the effects of good reproducibility and stability, inhibition of abnormal growth, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

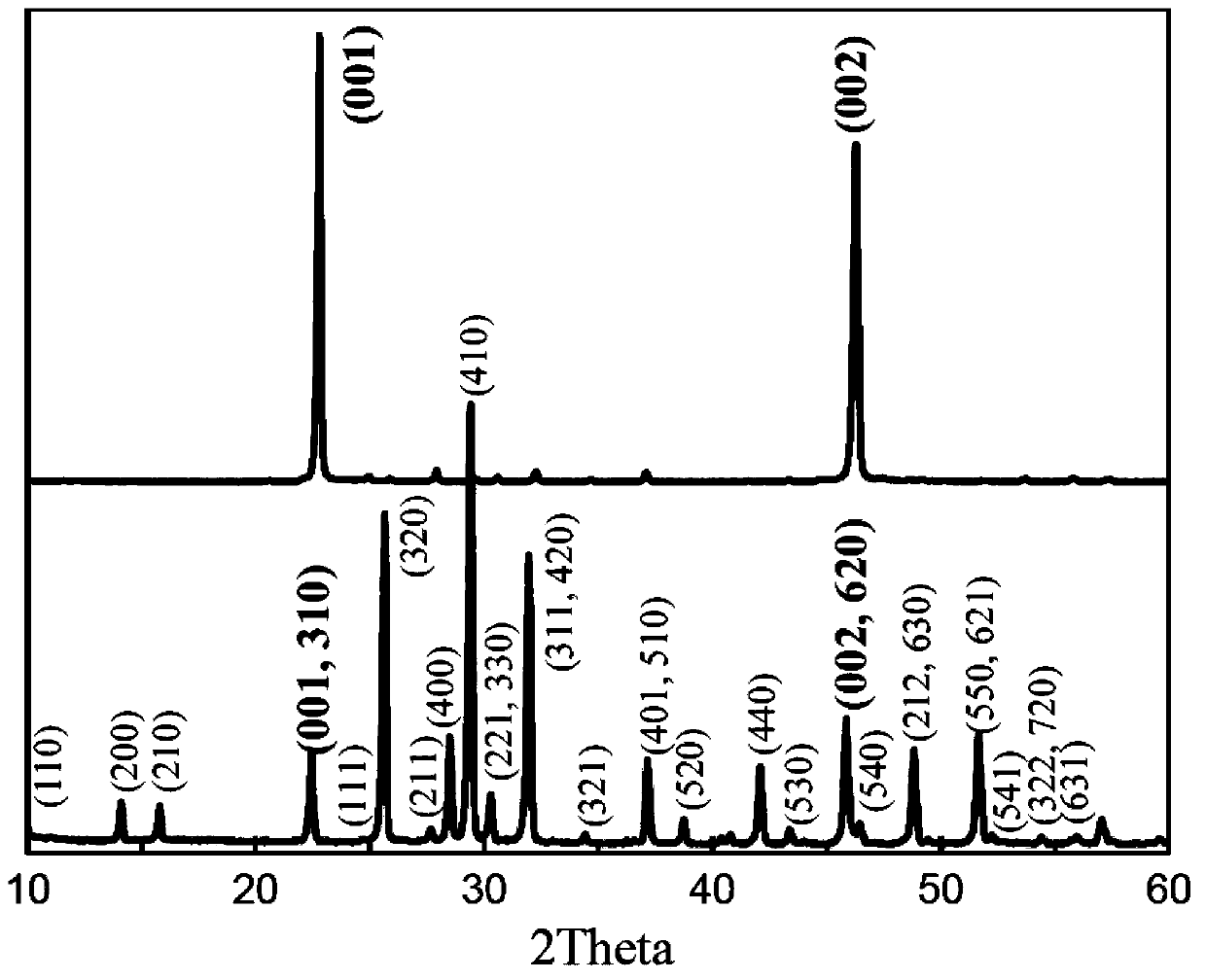

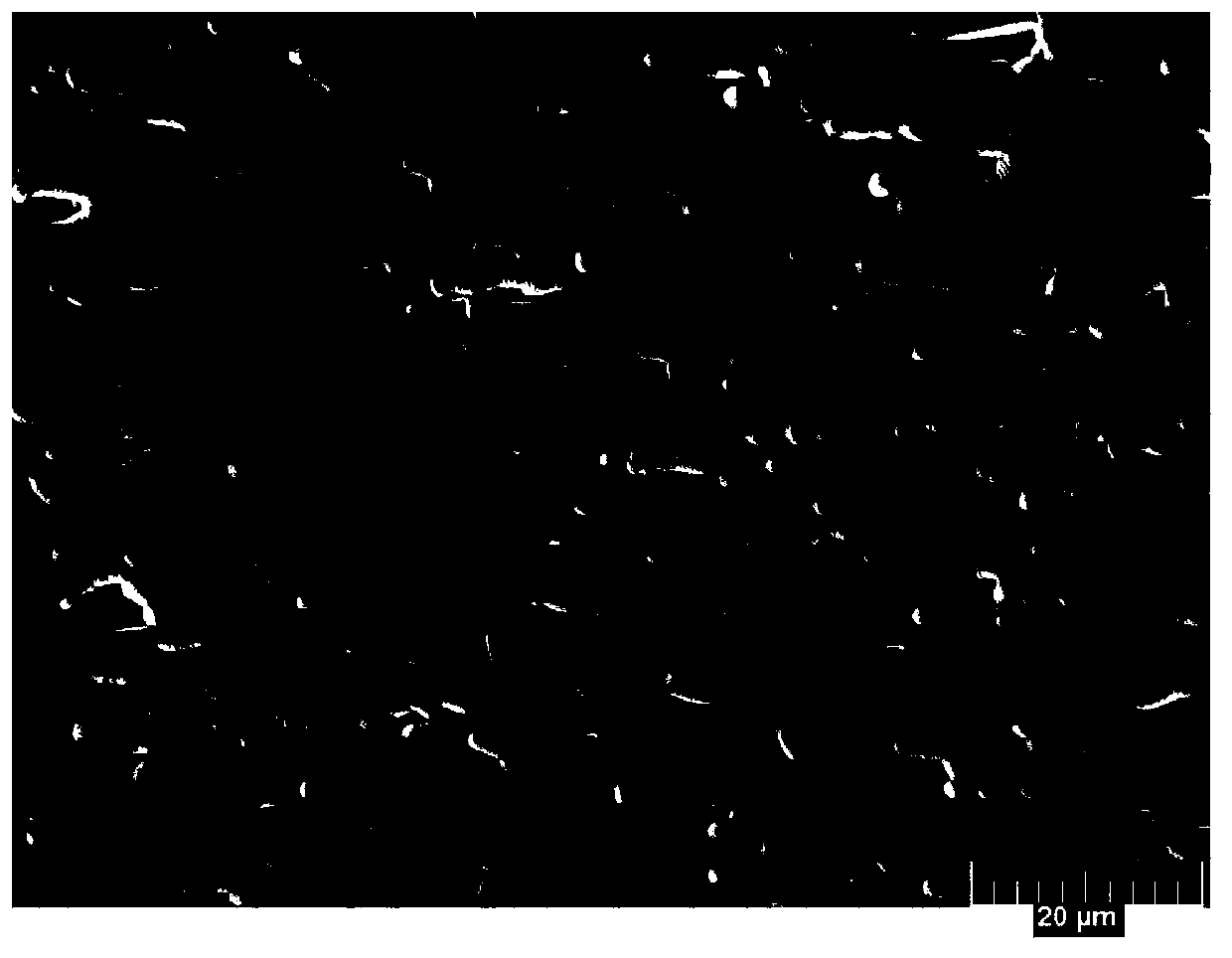

[0028] This embodiment is a lead-free potassium strontium niobate ceramic with a dense texture, and all oriented grains are evolved from needle-shaped potassium strontium niobate microcrystals. The original powder is acicular potassium strontium niobate microcrystalline powder, sintering aid, organic solvent and binder, of which:

[0029] Needle-shaped potassium strontium niobate microcrystalline powder is prepared from strontium carbonate, niobium pentoxide and potassium chloride by molten salt method.

[0030] The molar ratio of strontium carbonate to niobium pentoxide is 1:1.25, and potassium chloride is 1.5 times the weight of the mixture of strontium carbonate and niobium pentoxide. The sintering aid is bismuth trioxide, which is 4% of the weight of the needle-like potassium strontium niobate microcrystalline powder; the organic solvent is made of toluene and alcohol with a weight ratio of 2:1, and is the 50% of the weight of the crystal powder, and the binder adopts F51...

Embodiment 2

[0045] This embodiment is a lead-free potassium strontium niobate ceramic with a dense texture, and all oriented grains are evolved from needle-shaped potassium strontium niobate microcrystals. The original powder is acicular potassium strontium niobate microcrystalline powder, sintering aid, organic solvent and binder, of which:

[0046] Acicular strontium potassium niobate microcrystalline powder is prepared from strontium carbonate, niobium pentoxide and potassium chloride by molten salt method, wherein the molar ratio of strontium carbonate to niobium pentoxide is 1:1.25, Potassium chloride is 1.5 times the weight of the mixture of strontium carbonate and niobium pentoxide. The sintering aid is bismuth trioxide, which is 6% of the weight of the needle-shaped potassium strontium niobate microcrystalline powder; 60% of the weight of the crystal powder, and the binder adopts F518N ceramic powder binder produced in Fuzhou, which is 40% of the weight of the needle-like stronti...

Embodiment 3

[0061] This embodiment is a lead-free potassium strontium niobate ceramic with a dense texture, and all oriented grains are evolved from needle-shaped potassium strontium niobate microcrystals. The original powder is acicular potassium strontium niobate microcrystalline powder, sintering aid, organic solvent and binder, of which:

[0062] Acicular strontium potassium niobate microcrystalline powder is prepared from strontium carbonate, niobium pentoxide and potassium chloride by molten salt method, wherein the molar ratio of strontium carbonate to niobium pentoxide is 1:1.25, Potassium chloride is 1.5 times the weight of the mixture of strontium carbonate and niobium pentoxide. The sintering aid is bismuth trioxide, which is 2% of the weight of the needle-shaped potassium strontium niobate microcrystalline powder; the organic solvent is made of toluene and alcohol with a weight ratio of 2:1, which is the 60% of the weight of the crystal powder body, the binder adopts the F518...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com