Sand inclusion steel-plastic complex cable guide pipe

A technology of steel-plastic composite and cable conduit, applied in the direction of electrical components, etc., can solve the problems of low surface tension, poor creep resistance, poor dimensional stability, etc., and achieve the advantages of avoiding wear resistance, good mechanical properties and increased friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

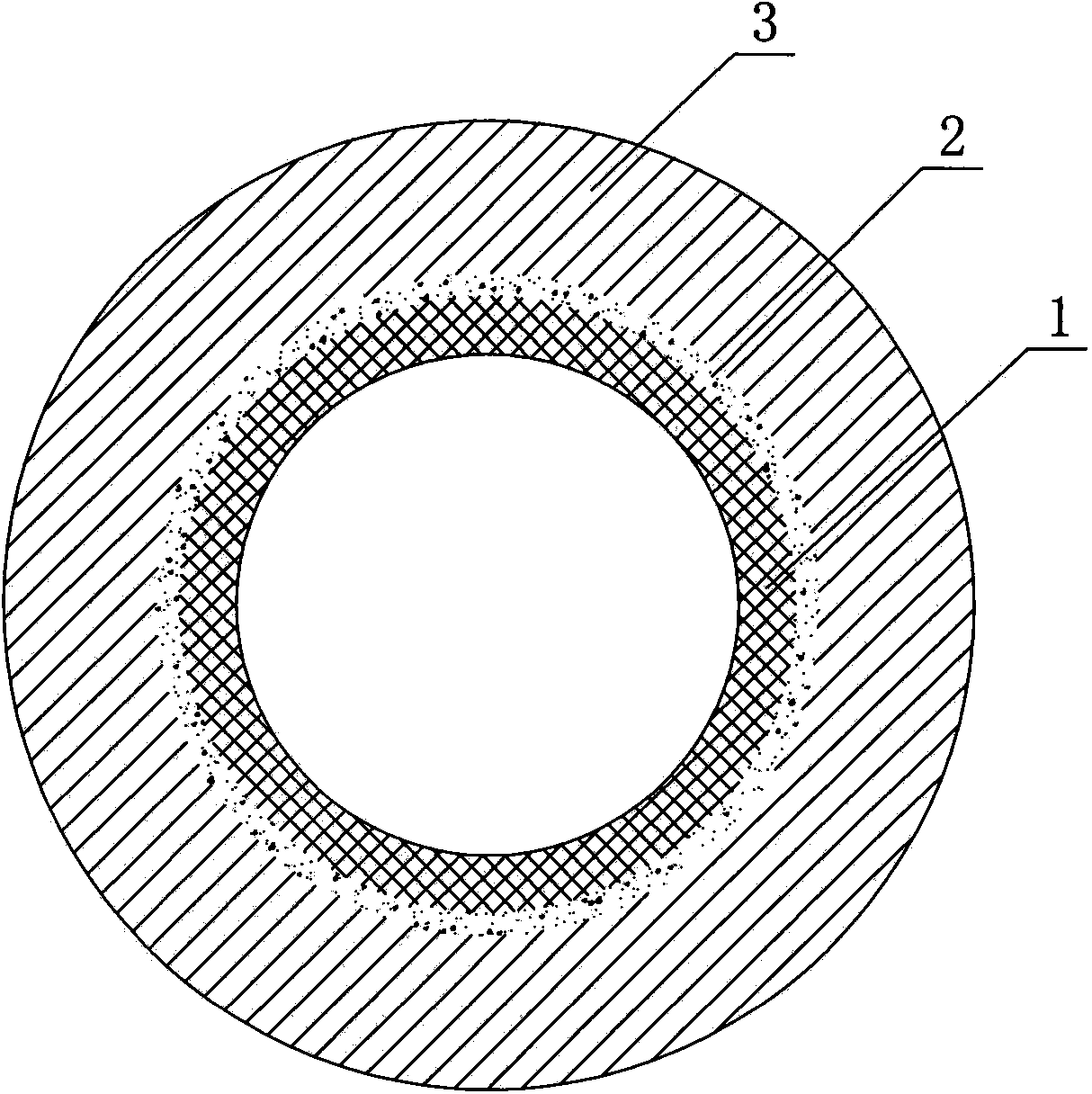

[0018] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0019] Such as figure 1 As shown, a sand-filled steel-plastic composite cable conduit includes a glass steel pipe 3 and a sand-filled pipe disposed therein.

[0020] The sand-filled pipe includes an inner pipe 1 and a quartz sand layer 2 composed of quartz sand particles squeezed into the outer layer of the inner pipe. Extend to both ends.

[0021] A silane coupling agent is attached to the outer surface of the quartz sand particles in the quartz sand layer 2 .

[0022] The particle size of the quartz sand is 0.3-1 mm.

[0023] The inner pipe 1 is a modified thermoplastic pipe made by blending thermoplastic particles and modified materials and extruding.

[0024] The modified material includes silane coupling agent, talcum powder and mineral powder. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com