Spherical LiFePO4/(C+La2/3-xLi3xTiO3) composite anode material and preparation method thereof

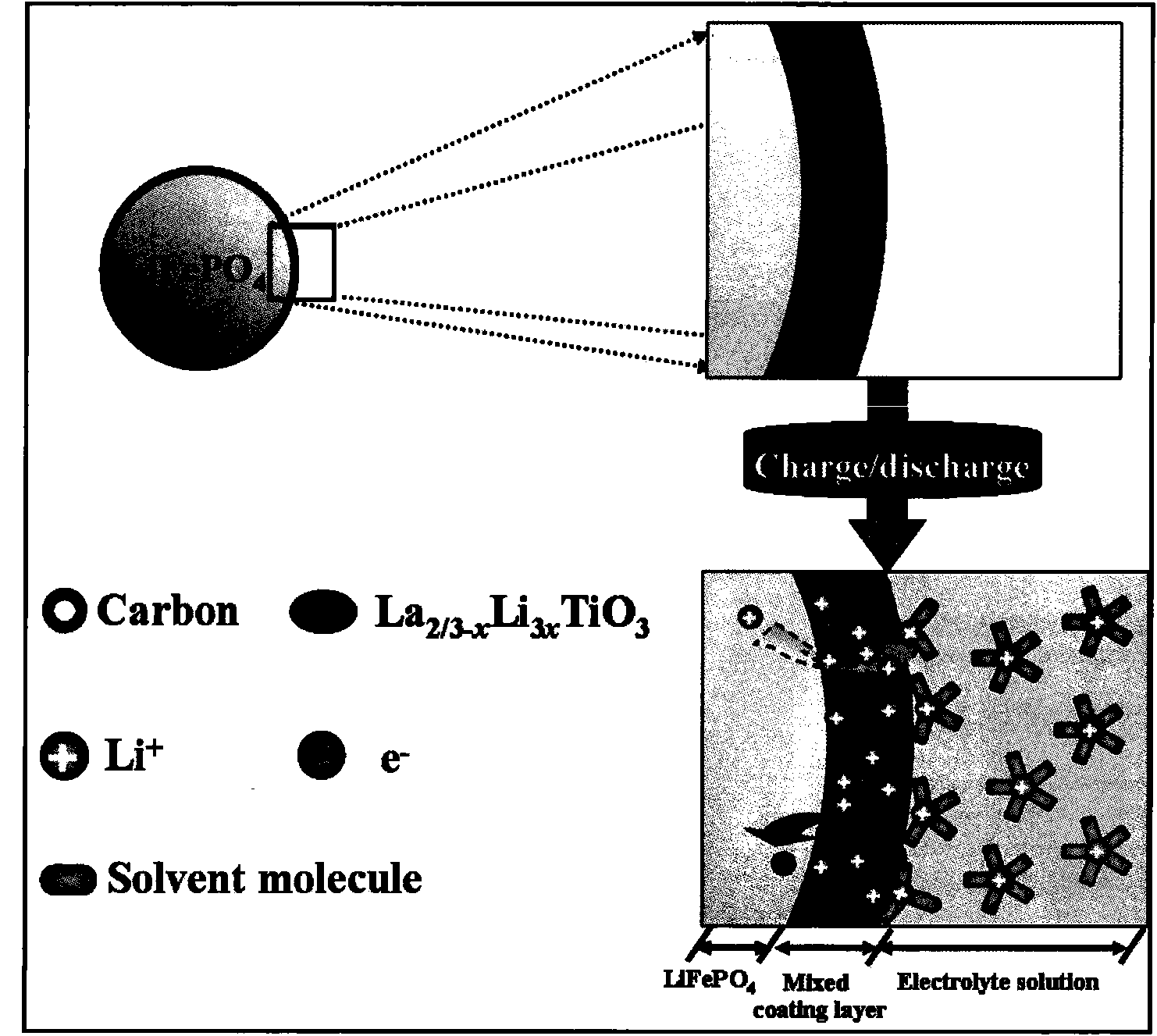

A positive electrode material and composite technology, applied in the field of spherical LiFePO4/composite positive electrode material and its preparation, can solve the problems of large battery size, inconvenient portability, unreachable lithium ion diffusion rate, unfavorable high rate performance of materials, etc., to achieve Improve electrochemical performance, improve discharge and cycle stability, and prevent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

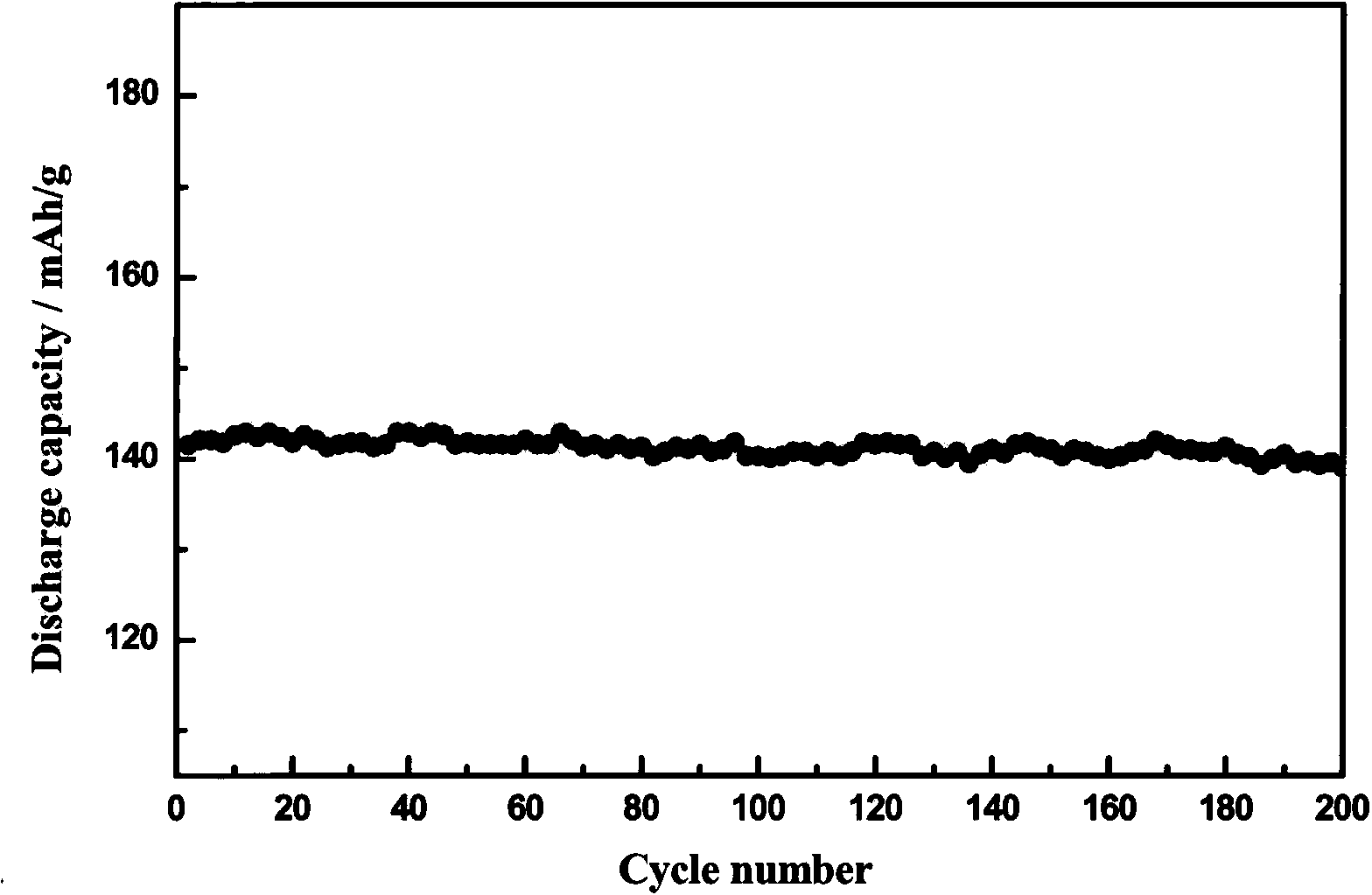

Embodiment 1

[0031] 1.03g LiCO 3 , 1.85g (NH 4 ) 2 HPO 4 , 2.69g citric acid and 5.66g Fe(NO 3 ) 3 9H 2 O mix well, make 70ml aqueous solution, add 0.11g La 0.47 Li 0.60 TiO 3 Mix evenly, then add 1.05g of glycine and mix evenly to obtain a mixed solution, then transfer it to a 100mL lined autoclave, seal it, react with water heat at 190°C for 3.5h, cool, and remove it after the temperature of the reactor drops to room temperature. Solvent to obtain the lithium iron phosphate precursor; after mixing the lithium iron phosphate precursor and 0.44g sucrose in deionized water evenly, stirring and drying at 60°C to obtain the mixture, and then calcining the mixture at 680°C for 8h in an Ar atmosphere, naturally Spherical LiFePO was obtained after cooling 4 / (C+La 0.47 Li 0.60 TiO 3 ) composite cathode material.

[0032] Spherical LiFePO 4 / (C+La 0.47 Li 0.6 TiO 3 ) electronic conductivity from the pure phase of 10-9 S / cm increased to 10 -1 On the order of S / cm, the diffusion r...

Embodiment 2

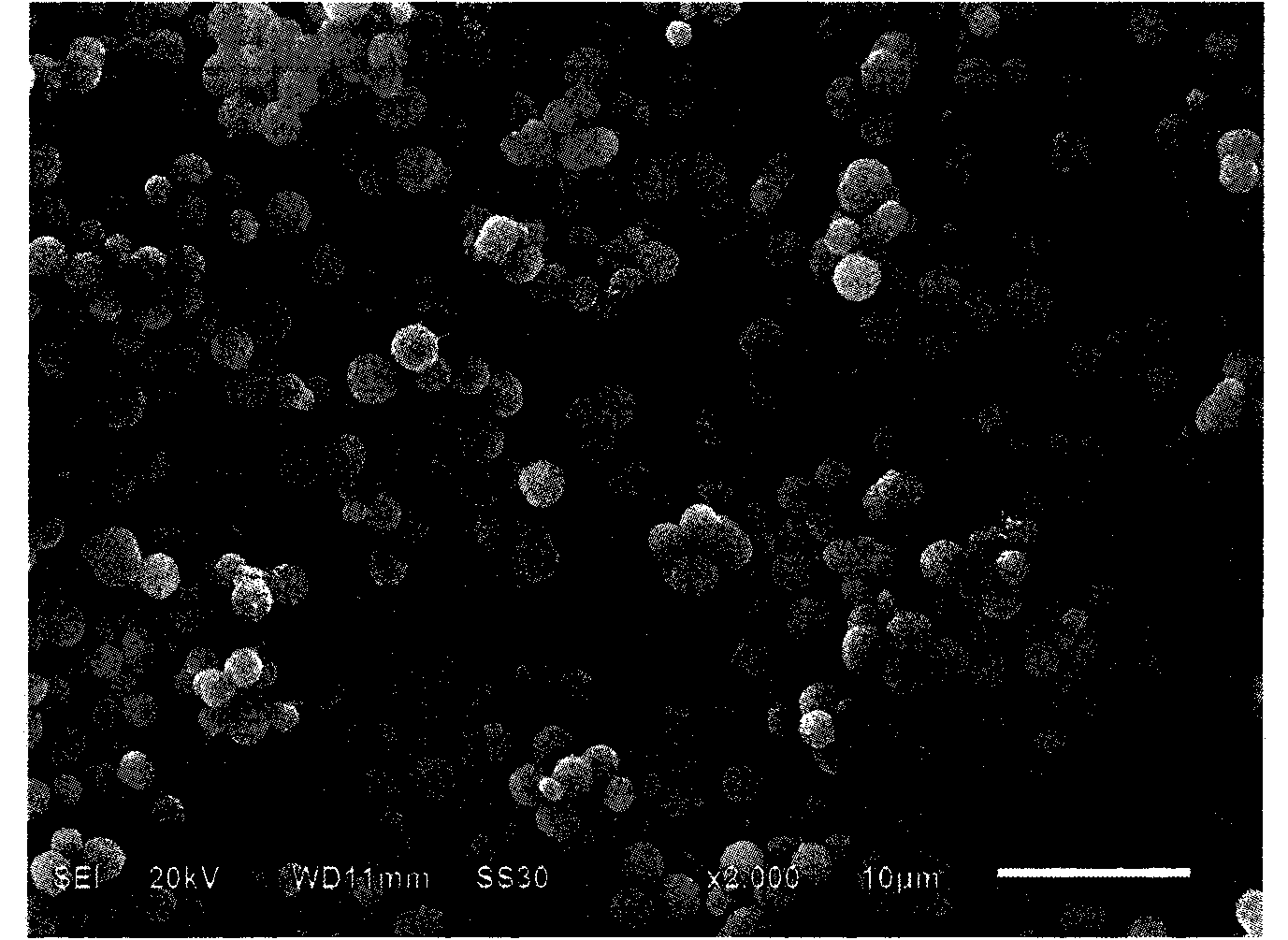

[0036] 1.17g LiOH·H 2 O, 3.22g NH 4 h 2 PO 4 , 5.38g citric acid and 11.31g Fe(NO 3 ) 3 9H 2 O mixed evenly, made into 70ml aqueous solution, added 2ml of ammonia water with a concentration of 14mol / L and mixed evenly to obtain a mixed solution, then transferred the mixed solution into a 100mL lined autoclave, sealed, and hydrothermally reacted at 180°C for 6h, Cooling, remove the solvent after the reaction kettle temperature is down to room temperature, obtain the lithium iron phosphate precursor; The lithium iron phosphate precursor is mixed with 1.33g citric acid and 0.11g La 0.56 Li 0.33 TiO 3 After mixing evenly in ethanol, stir and dry at 60°C to obtain the mixture, then calcinate the mixture at 700°C for 10 h in an Ar atmosphere, and obtain spherical LiFePO after natural cooling. 4 / (C+La 0.56 Li 0.33 TiO 3 ) composite cathode material.

[0037] image 3 For spherical LiFePO 4 Precursor, Figure 4 For spherical LiFePO 4 / (C+La 0.56 Li 0.33 TiO 3 ) SEM...

Embodiment 3

[0039] 2.04g CH 3 COOLi·2H 2 O, 2.64g (NH 4 ) 2 HPO 4 , 2.50g oxalic acid and 1.60g Fe 2 o 3 Mix evenly to make 60ml of aqueous solution, add 1.46g of diethylamine and mix evenly to obtain a mixed solution, then transfer the mixed solution into a 100mL lined high-pressure reactor, seal it, and conduct a hydrothermal reaction at 160°C for 8 hours, cool, and wait for After the temperature of the reactor is lowered to room temperature, the solvent is removed to obtain a lithium iron phosphate precursor; the lithium iron phosphate precursor is heated in Ar / H 2 Atmosphere (Ar volume ratio is 90%, H 2 Calcined at 650 °C for 8 h in a volume ratio of 10%, and obtained spherical LiFePO after natural cooling 4 Cathode material; spherical LiFePO 4 Cathode material and 0.79g sucrose and 0.19g La 0.49 Li 0.54 TiO 3 After mixing uniformly in an aqueous solution, stir and dry at 70°C to obtain a mixture, and then place the mixture in Ar / H 2 Atmosphere (Ar volume ratio is 90%, H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com