Corona-resistant groove insulation material and preparation method thereof

A technology of slot insulation and corona resistance is applied in the field of corona-resistant composite materials of slot insulation and its preparation, which can solve the problem of poor corona resistance life, inability to improve the resistance of variable frequency motors to high-frequency pulse voltage, and inability to meet the use requirements of variable frequency motors and other problems, to achieve the effect of strong impregnation, improving mechanical properties and electrical insulation properties, and reducing partial discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

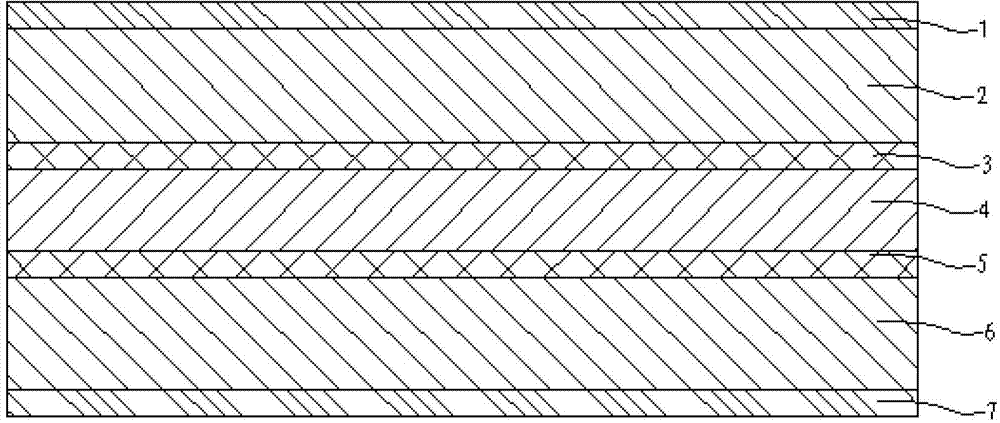

[0025] This embodiment provides a corona-resistant tank insulating material, and its preparation method is as follows: on the coating composite equipment, the polyester film with a thickness of 0.05mm is unwound, dipped in nano-modified adhesive glue solution A, and scraped on both sides, Baking in the drying tunnel to remove the solvent, composite the mica paper with a thickness of 0.10mm on both sides, hot-press composite, evenly coat the nano-modified adhesive glue B on the mica paper on both sides, dry in the drying tunnel, cool, and wind up. Post-curing treatment, edge trimming, the corona-resistant insulation material is obtained, and the adhesive content is 15.6%.

[0026] The above nano-modified adhesive glue A is composed of 36% nano-modified epoxy adhesive and 64% solvent (toluene + acetone);

[0027] The above nano-modified adhesive solution B is composed of 18% nano-modified epoxy adhesive and 72% solvent (toluene + acetone);

[0028] The above-mentioned nano-modi...

Embodiment 2

[0030] This embodiment provides a corona-resistant tank insulating material, and its preparation method is as follows: on the coating composite equipment, the polyimide film with a thickness of 0.05 mm is unrolled, dipped in nano-modified adhesive glue solution A, and scraped on both sides. Adhesive, baked in a drying tunnel to remove solvent, laminated mica paper with a thickness of 0.11 mm on both sides, hot-pressed and laminated, evenly coated nano-modified adhesive glue B on both sides of the mica paper, dried in a drying tunnel, cooled, and collected Roll, post-curing treatment, and edge trimming, the corona-resistant insulation material is obtained, and the adhesive content is 18.5%.

[0031] The above nano-modified adhesive glue A is composed of 40% nano-modified epoxy adhesive and 60% solvent (toluene + acetone);

[0032] The above nano-modified adhesive solution B is composed of 15% nano-modified epoxy adhesive and 85% solvent (toluene + acetone);

[0033] The above ...

Embodiment 3

[0035] This embodiment provides a corona-resistant tank insulating material, the preparation method of which is as follows: on the coating composite equipment, the polyester film with a thickness of 0.10mm is unwound, dipped in nano-modified adhesive glue solution A, and scraped on both sides. Baking in the drying tunnel to remove the solvent, composite the mica paper with a thickness of 0.12mm on both sides, hot-press composite, and evenly coat the nano-modified adhesive glue B on the mica paper on both sides, dry in the drying tunnel, cool, and wind up. Post-curing treatment, edge trimming, the corona-resistant insulation material is obtained, and the adhesive content is 13.7%.

[0036] The above nano-modified adhesive solution A is composed of 35.1% nano-modified epoxy adhesive and 64.9% solvent (toluene + acetone);

[0037] The above nano-modified adhesive solution B is composed of 14.8% nano-modified epoxy adhesive and 85.2% solvent (toluene + acetone);

[0038] The abov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com