a heat insulating tile

A heat-insulating tile and bottom layer technology, which is applied to roofs, roofs, buildings, etc. that use tiles/slate tiles, can solve problems such as poor fire resistance, weather resistance, and easy to fall off, and achieve the effect of strong fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

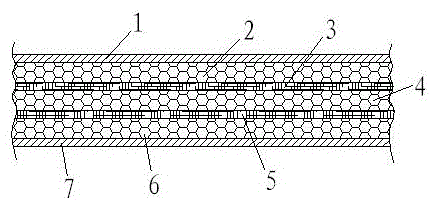

[0017] Mix 60 parts of magnesium oxide, 3 parts of waste circuit board powder, 3 parts of sawdust, 30 parts of stone powder, 20 parts of magnesium chloride aqueous solution with a concentration of 25%, and 8 parts of modifier to make a slurry, and then press the surface aluminum foil layer , slurry, glass fiber, slurry, glass fiber, slurry, and the order of the bottom aluminum foil layer, they are compounded together by co-extrusion, and transported to the heat-insulating tile template for molding, after a period of natural standing and curing , Carry out sawing treatment to make finished insulation tiles.

Embodiment 2

[0019] Mix 80 parts of magnesium oxide, 7 parts of waste circuit board powder, 7 parts of sawdust, 15 parts of stone powder, 30 parts of magnesium chloride aqueous solution with a concentration of 30%, and 5 parts of modifier to make a slurry, and press the aluminum foil layer on the surface in order. , slurry, glass fiber, slurry, glass fiber, slurry, and the sequence of the bottom polyethylene, they are compounded together by co-extrusion, and transported to the heat-insulating tile formwork for molding, after a period of natural standing and curing , Carry out sawing treatment to make finished insulation tiles.

Embodiment 3

[0021] Mix 70 parts of magnesium oxide, 5 parts of waste circuit board powder, 5 parts of sawdust, 20 parts of stone powder, 25 parts of magnesium chloride aqueous solution with a concentration of 27%, and 6 parts of modifier to make a slurry, and then press the aluminum foil layer on the surface , slurry, glass fiber, slurry, glass fiber, slurry, and the order of the bottom aluminum foil layer, they are compounded together by co-extrusion, and transported to the heat-insulating tile template for molding, after a period of natural standing and curing , Carry out sawing treatment to make finished insulation tiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com