Preparation method and application of metal-doped titanium dioxide material

A titanium dioxide and metal doping technology, which is applied in chemical instruments and methods, textile industry wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of low solar energy utilization efficiency, difficulty in recycling, waste of resources and cost, etc. , to achieve good photodegradability, good application potential, cost and resource savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: the preparation of pure titanium dioxide

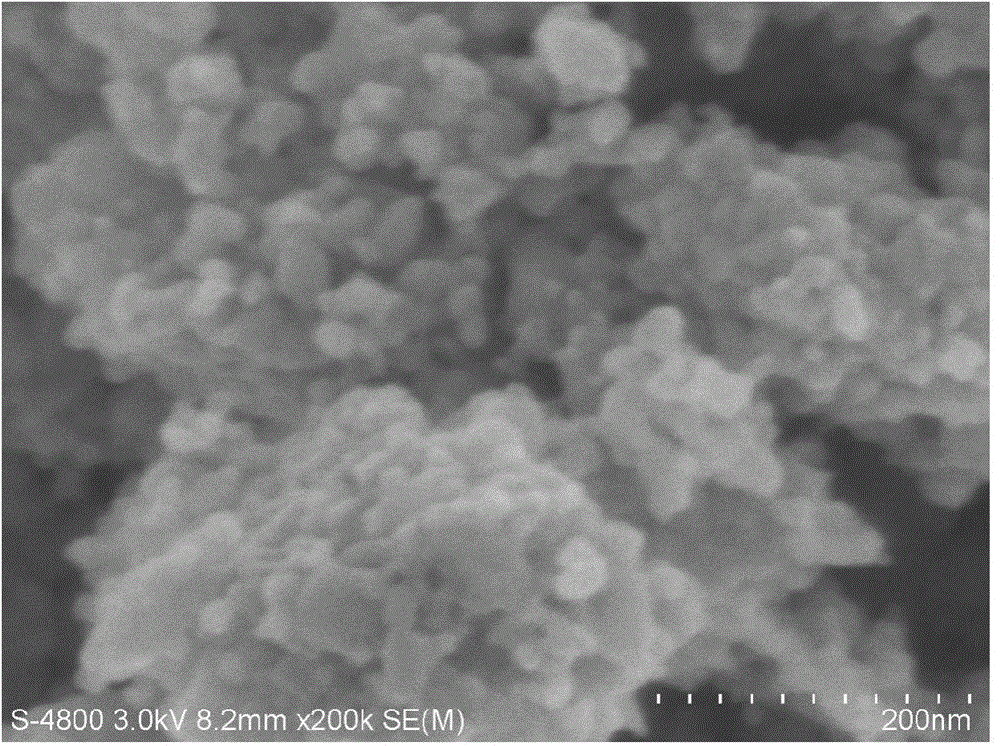

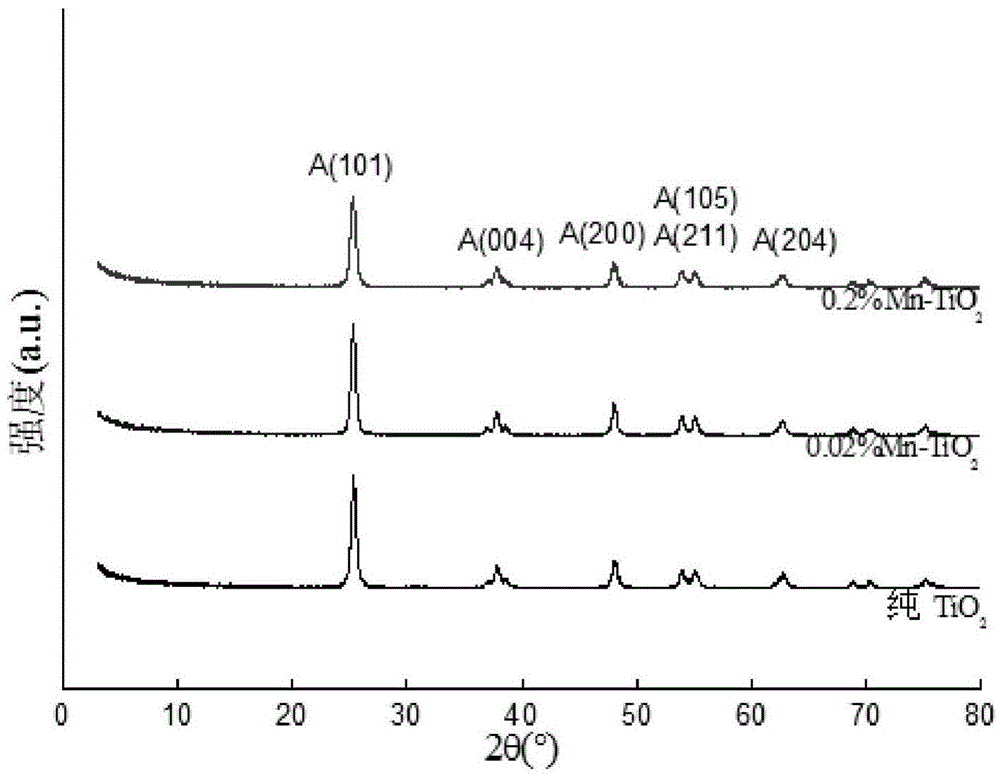

[0031] First, tetrabutyl titanate and absolute ethanol were mixed at a volume ratio of 1:4, and stirred evenly at room temperature; after continuous stirring for 2 hours, the solution was put into a drying dish containing 1.0 g / mL potassium carbonate aqueous solution at the bottom, After 10 days, the mixture forms a gel, and then dried in an oven at 80°C for 12 hours. After cooling, the obtained particles were first washed with absolute ethanol, then washed once with distilled water, dried at 100°C after centrifugation, and then placed in a tube furnace Raise the temperature to 500°C at a rate of 5°C / min, continue to feed air, calcine for 3 hours, and then naturally cool to room temperature to obtain pure titanium dioxide particles. figure 1 It can be seen from the scanning electron microscope image that the average particle size of the nanomaterial is about 20nm; image 3 According to its XRD pattern, it can be ...

Embodiment 2

[0032] Embodiment 2: The molar ratio is the preparation of 2.0% tungsten-doped titanium dioxide

[0033] First, tetrabutyl titanate and absolute ethanol are mixed in a volume ratio of 1:4, and stirred evenly at room temperature; then 0.5wt% ethanol solution of tungsten chloride is added to make the molar ratio of tungsten and titanium to 2.0%, forming Mixed solution doped with ions; after stirring continuously for 2 hours, put the solution into a drying dish filled with 600 mg / mL potassium carbonate aqueous solution at the bottom, after 5 days, the mixed solution forms a gel, and then dry it in an oven at 80°C for 12 hours, cool The obtained particles were first washed with absolute ethanol, then washed once with distilled water, dried at 100°C after centrifugation, and then placed in a tube furnace to raise the temperature to 500°C at a rate of 5°C / min, continue to feed air, and calcined for 3 hours After cooling naturally to room temperature, the molar ratio of 2.0% tungsten...

Embodiment 3

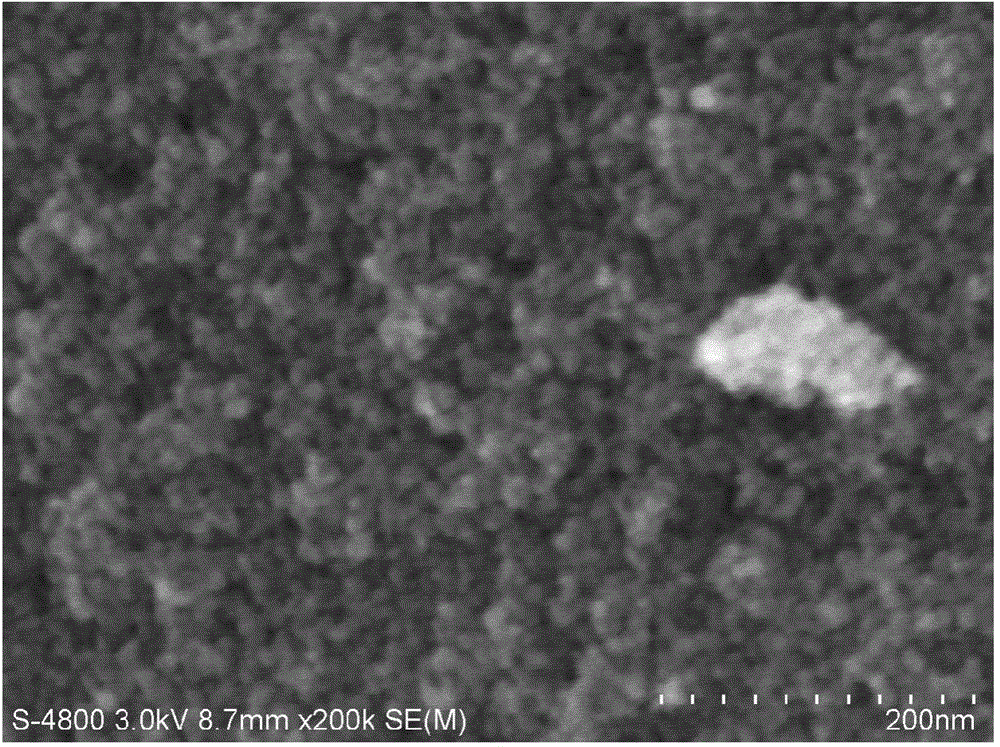

[0034] Embodiment 3: the molar ratio is the preparation of 0.02% manganese-doped titanium dioxide

[0035] First, tetrabutyl titanate and absolute ethanol are mixed at a volume ratio of 1:4, and stirred evenly at room temperature; then 0.05wt% ethanol solution of manganese acetate is added to make the molar ratio of manganese and titanium 0.02%, forming ions Doped mixed solution; after continuous stirring for 2h, the solution was put into a dry dish filled with 600g / mL potassium carbonate aqueous solution at the bottom. After 5 days, the mixture formed a gel, and then dried in an oven at 80°C for 12 hours. After cooling, the obtained particles were first washed with absolute ethanol, then washed once with distilled water, dried at 100°C after centrifugation, and then placed in a tube furnace. The temperature was raised to 500°C at a rate of 5°C / min, air was continuously introduced, and after calcination for 3 hours, it was naturally cooled to room temperature to obtain titaniu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com