Paper coating compositions

A composition and paper technology, applied in the direction of paper coating, papermaking, coating, etc., can solve problems such as rough surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

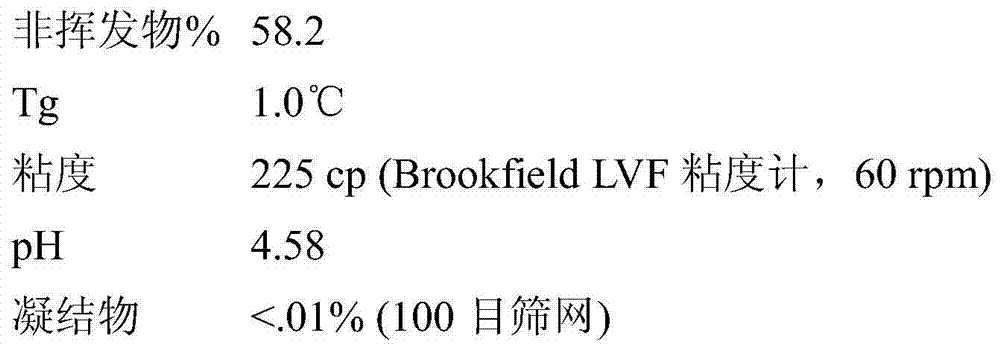

Embodiment 1

[0037] The autoclave is charged with 850g water, 8.8g MA-80-I (sodium dihexyl sulfosuccinate), 0.5g sodium acetate, 5.0g 1% ferrous ammonium sulfate solution. The pH of the feed was adjusted to 4.2 with 1.1 g of acetic acid. Stirring was started and 262.5 g of vinyl acetate was added.

[0038] After the initial charge, the reactor was purged with nitrogen, then with ethylene, and heated to 55°C with stirring, followed by the charge of 400 g of ethylene. To initiate the polymerization, a 6% sodium persulfate solution was fed at 0.5 g / min and a 3.6% sodium erythorbate solution was additionally fed at 0.5 g / min. When there was evidence of an exotherm, two additional feeds were started: 1277.5 g of vinyl acetate over 150 minutes, and a uniform feed of 187.2 g of water, 38.7 g of L64 (ethylene oxide / propylene oxide block copolymer supplied by BASF), 38.7 g 2403 (a 50% solution of acrylamidomethyl propane sulfonate sodium salt supplied by Lubrizol), 19.5 g of acrylic acid and...

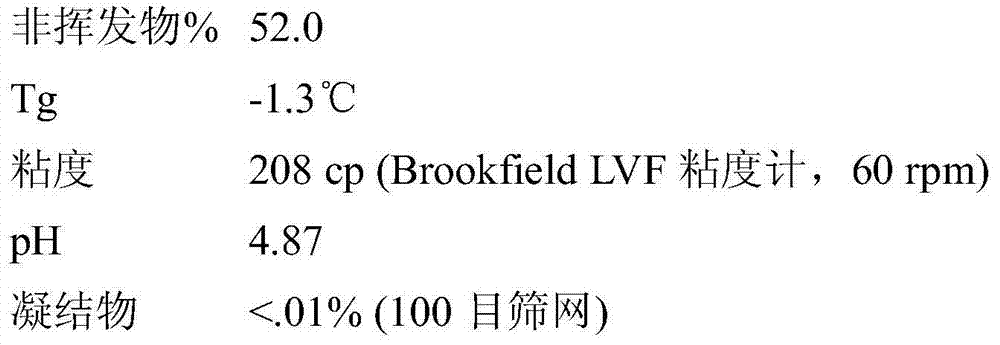

Embodiment 2

[0045] The autoclave is charged with 900g water, 10.5g MA-80-I (sodium dihexyl sulfosuccinate), 0.5g sodium acetate, 5.0g 1% ferrous ammonium sulfate solution. The pH of the feed was adjusted to 4.2 with 1.1 g of acetic acid. Stirring was started and 354 g of vinyl acetate was added.

[0046] After the initial charge, the reactor was purged with nitrogen, then with ethylene, and heated to 55°C with stirring, followed by the charge of 400 g of ethylene. To initiate the polymerization, a 3% sodium persulfate solution was fed at 0.5 g / min and a 1.8% sodium erythorbate solution was additionally fed at 0.5 g / min. When there was evidence of an exotherm, two additional feeds were started: 1061 g of vinyl acetate was added over 120 minutes, and a mixture of 314.2 g of water, 16.7 g of RS-610 (phosphate ester of tridecyl alcohol ethoxylate supplied by Rhodia), 16.7 g L64 (ethylene oxide / propylene oxide block copolymer supplied by BASF), 16.7 g 2403 (a 50% solution of acrylamid...

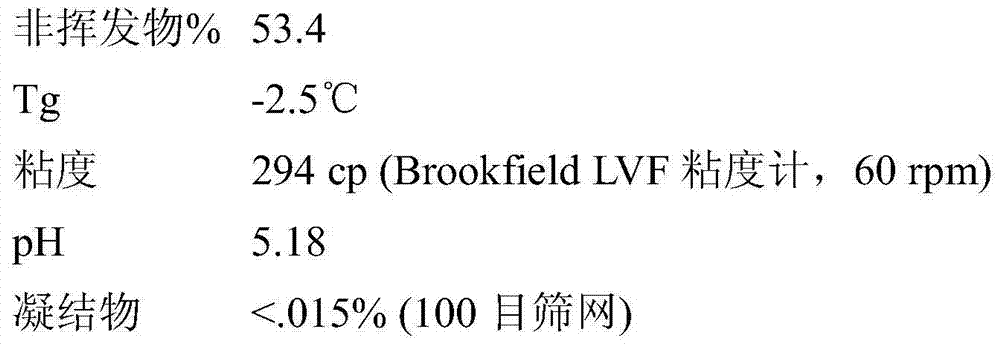

Embodiment 3

[0053] According to the method and steps of Example 2, except that the aqueous feed is adjusted to contain: 281.3g water, 66.8g TLA4050 (50% solution of tridecyl alcohol ethoxylate with 40 moles of ethylene oxide supplied by Rhodia), 16.7 g 2403 (50% solution of sodium salt of acrylamidomethyl propane sulfonate supplied by Lubrizol), 16.7 g of acrylic acid and 15.5 g of 7% ammonium hydroxide.

[0054] Additionally, the 3% sodium persulfate solution was adjusted to contain 2% sodium bicarbonate.

[0055]As in Example 1, the addition rates of sodium persulfate and sodium erythorbate were adjusted over time in an attempt to obtain a uniform conversion distribution. The two additions were terminated 165 minutes after an initial exotherm was observed when 150 g of each solution had been added.

[0056] After the end of the feed, the remaining conditions were the same as in Example 1.

[0057] The physical property of gained latex is:

[0058]

[0059] Estimated polymer com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com