Preparation method of signal amplifying type quantum dot immune fluorescent probe and application of signal amplifying quantum dot immune fluorescent probe

A technology of immunofluorescence and quantum dots, which is applied in the field of immunoassay, can solve the problems of low detection sensitivity and low signal, and achieve the effect of high detection sensitivity, good repeatability and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

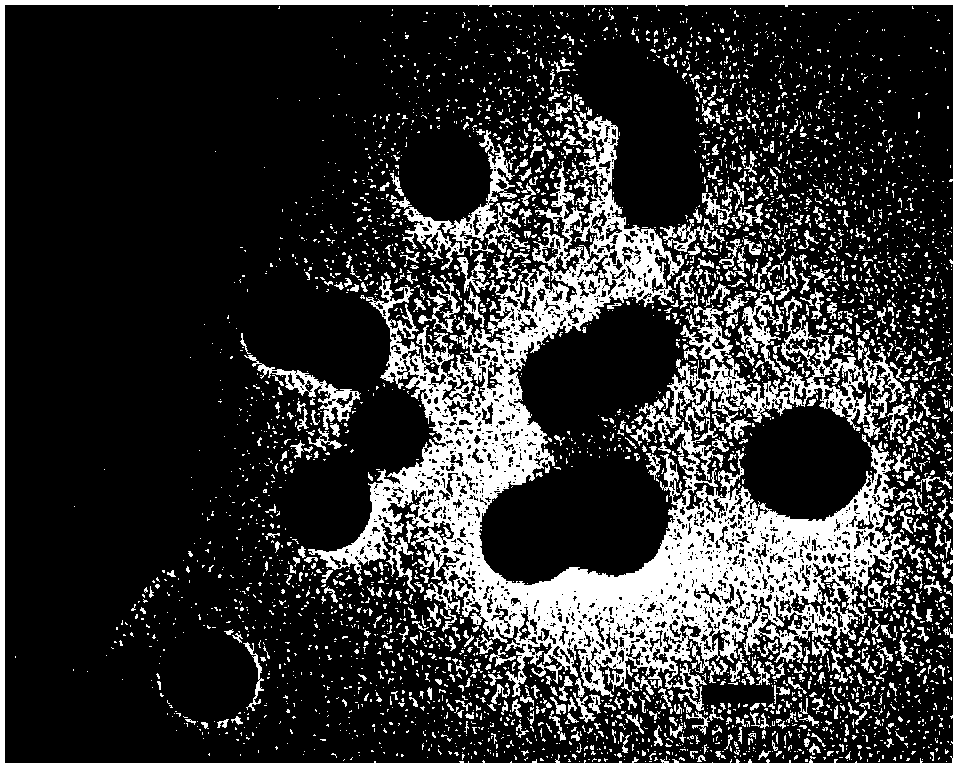

[0052] Embodiment 1: Preparation of quantum dot-polymer composite nanosphere

[0053] The preparation of CdSe / ZnS quantum dot-polymer composite nanosphere comprises the following steps:

[0054] A. Oil phase components: CdSe / ZnS quantum dots and polystyrene-maleic anhydride copolymer are dispersed in chloroform solution, the concentration of quantum dots is 0.1μmol / L, and the concentration of polymer is 0.05mg / mL;

[0055] B. Water phase components: Polyvinyl alcohol and sodium dodecylsulfonate are configured into an aqueous solution, wherein the concentration of polyvinyl alcohol is 2.5%, and the concentration of sodium dodecylsulfonate is 0.5%;

[0056] C. In a water bath at 4°C, under magnetic stirring, add the oil phase solution to the water phase solution, and keep stirring for 60 minutes, and then use a sonicator to sonicate the solution for 10 minutes to obtain a uniform and stable microemulsion.

[0057] D, at room temperature, the microemulsion is placed in an open c...

Embodiment 2

[0063] Embodiment 2: Preparation of quantum dot-polymer composite nanosphere

[0064] A. Oil phase components: CdSe quantum dots and polystyrene-acrylic acid copolymer are dispersed in chloroform solution, the concentration of quantum dots is 2.5 μmol / L, and the concentration of polymer is 1.0 mg / mL;

[0065] B. Water phase components: Polyvinyl alcohol and sodium dodecylsulfonate are configured into an aqueous solution, wherein the concentration of polyvinyl alcohol is 0.5%, and the concentration of sodium dodecylsulfonate is 0.25%;

[0066] C. In a water bath at 4°C, under magnetic stirring, add the oil phase solution to the water phase solution, continue stirring for 10 minutes, and then use a sonicator to sonicate the solution for 3 minutes to obtain a uniform and stable microemulsion.

[0067] D, at room temperature, the microemulsion is placed in an open container, under magnetic stirring, the solvent is gradually volatilized, the volatilization time is 24 hours, centrif...

Embodiment 3

[0072] Embodiment 3: Preparation of quantum dot-polymer composite nanosphere

[0073] A. Oil phase components: Disperse CuInS quantum dots and polymethyl methacrylate-methacrylic acid copolymer in chloroform solution, the concentration of quantum dots is 0.1 μmol / L, and the concentration of polymer is 0.05 mg / mL;

[0074] B. Water phase components: Polyvinyl alcohol and sodium dodecylsulfonate are configured into an aqueous solution, wherein the concentration of polyvinyl alcohol is 2.5%, and the concentration of sodium dodecylsulfonate is 0.5%;

[0075] C. In a water bath at 4°C, under magnetic stirring, add the oil phase solution to the water phase solution, and keep stirring for 60 minutes, and then use a sonicator to sonicate the solution for 10 minutes to obtain a uniform and stable microemulsion.

[0076] D, at room temperature, the microemulsion is placed in an open container, under magnetic stirring, the solvent is gradually volatilized, the volatilization time is 6 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com