Method for co-production of aramid fiber scale m-phenylenediamine and resorcinol

A m-phenylenediamine and resorcinol technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high energy consumption, low concentration of mother liquor, loss of m-phenylenediamine, etc., and achieve The effect of reducing manufacturing difficulty and simplifying the crystallization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

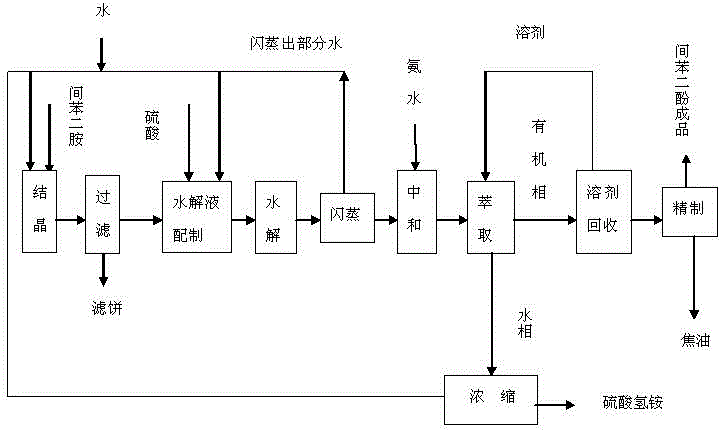

Image

Examples

Embodiment 1

[0024] Embodiment 1: produce aramid grade m-phenylenediamine and resorcinol according to the following steps

[0025] (1) Crystallization: Mix crude m-phenylenediamine and water into an aqueous solution with a mass concentration of 20% m-phenylenediamine, cool to 5°C under stirring, part of m-phenylenediamine crystallizes out and there is a small amount of o-phenylenediamine and p-phenylenediamine precipitation;

[0026] (2) Filtration: filter the above-mentioned cooled m-phenylenediamine aqueous solution, and the filter cake is used to prepare aramid-grade m-phenylenediamine;

[0027] (3) Preparation of raw material solution for hydrolysis: add appropriate amount of sulfuric acid and water to the filtered mother liquor, and prepare the filtered mother liquor into a hydrolyzed raw material solution whose mass composition is m-phenylenediamine: sulfuric acid: water = 4:7.33:88.67;

[0028] (4) Hydrolysis: Heat the above-mentioned hydrolysis raw material solution to 200°C and s...

Embodiment 2

[0034] Embodiment 2: produce aramid grade m-phenylenediamine and resorcinol according to the following steps:

[0035] (1) Crystallization: Mix crude m-phenylenediamine and water into an aqueous solution with a mass concentration of 50% m-phenylenediamine, cool to 10°C under stirring, part of the m-phenylenediamine crystallizes out and there is a small amount of o-phenylenediamine and p-phenylenediamine precipitation;

[0036] (2) Filtration: filter the above-mentioned cooled m-phenylenediamine aqueous solution, and the filter cake is used to prepare aramid-grade m-phenylenediamine;

[0037] (3) Preparation of raw material solution for hydrolysis: add appropriate amount of sulfuric acid and water to the filtered mother liquor, and prepare the filtered mother liquor into a hydrolysis raw material solution whose mass composition is m-phenylenediamine: sulfuric acid: water = 6:11:83;

[0038] (4) Hydrolysis: Heat the above-mentioned hydrolysis raw material solution to 220°C and ...

Embodiment 3

[0044] Embodiment 3: produce aramid grade m-phenylenediamine and resorcinol according to the following steps

[0045] (1) Crystallization: Mix crude m-phenylenediamine and water into an aqueous solution with a mass concentration of 70% m-phenylenediamine, cool to 20°C under stirring, part of the m-phenylenediamine crystallizes out and there is a small amount of o-phenylenediamine and p-phenylenediamine precipitation;

[0046] (2) Filtration: filter the above-mentioned cooled m-phenylenediamine aqueous solution, and the filter cake is used to prepare aramid-grade m-phenylenediamine;

[0047] (3) Preparation of raw material solution for hydrolysis: add appropriate amount of sulfuric acid and water to the filtered mother liquor, and prepare the filtered mother liquor into a hydrolyzed raw material solution whose mass composition is m-phenylenediamine: sulfuric acid: water = 15:27.5:57.5;

[0048] (4) Hydrolysis: Heat the above-mentioned hydrolysis raw material solution to 280°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com