Preparation method of acid-tolerant non-dairy creamer

A technology of vegetable fat powder and acid-resistant type, applied in the field of preparation of acid-resistant vegetable fat powder, can solve the problems of limited application of vegetable fat powder, stratified precipitation, difficult to dissolve, etc., and achieves good low temperature dissolution effect, short production cycle, seasonality stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

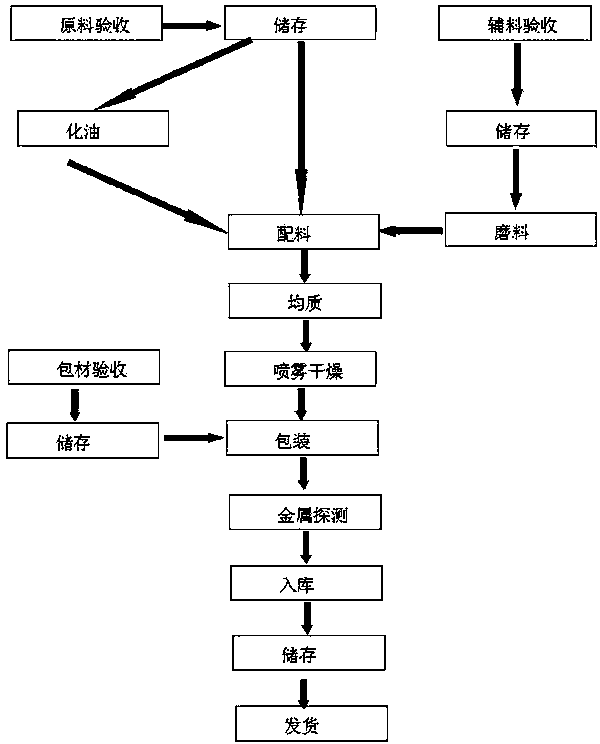

Image

Examples

Embodiment 1

[0024] (1) Preparation of the oil phase: Weigh 280kg of hydrogenated coconut oil stripped of the carton and inner film, put it into the oil pot, open the steam valve to heat to melt, and close the valve when the temperature reaches 70°C. Add 5 kg of monoglyceride fatty acid ester and 0.5 kg of sodium stearoyl lactylate, and stir for 20 minutes for later use.

[0025] (2) Preparation of water phase: Pour 5kg of sodium caseinate, 5kg of dipotassium hydrogen phosphate, and 2kg of sodium tripolyphosphate into a certain amount of ion-free water, stir at high speed, and after fully dissolved, pass through a colloid mill to make it uniform. become a paste.

[0026] (3) Mixing and shearing: First put 600kg (dry basis) of maltodextrin into the mixing tank, then put the paste liquid in step 2 and keep stirring, after a certain period of time, add the oil phase in step 1, Keep stirring to keep the temperature of the material liquid at 60-70°C, and then use high-speed shearing for 15 min...

Embodiment 2

[0031] (1) Preparation of the oil phase: Weigh 300kg of hydrogenated coconut oil stripped of the carton and inner film, put it into the oil pot, open the steam valve to heat to melt, and close the valve when the temperature reaches 70°C. Add 10 kg of monoglyceride fatty acid ester and 1 kg of sodium stearoyl lactylate, and stir for 20 minutes for later use.

[0032] (2) Preparation of water phase: Pour 10kg of sodium caseinate, 11kg of dipotassium hydrogen phosphate, and 3kg of sodium tripolyphosphate into a certain amount of ion-free water, stir at high speed, and after fully dissolved, pass through a colloid mill to make it uniform. become a paste.

[0033] (3) Mixing and shearing: first put 649kg (dry basis) of maltodextrin into the mixing tank, then put the paste liquid in step 2 and keep stirring, after a certain period of time, add the oil phase in step 1, Keep stirring to keep the temperature of the material liquid at 60-70°C, and then use high-speed shearing for 15 mi...

Embodiment 3

[0038] (1) Preparation of the oil phase: Weigh 320kg of hydrogenated coconut oil stripped of the carton and inner film, put it into the oil pot, open the steam valve to heat to melt, and close the valve when the temperature reaches 70°C. Add 15 kg of monoglyceride fatty acid ester and 1.5 kg of sodium stearoyl lactylate, and stir for 20 minutes for later use.

[0039] (2) Preparation of water phase: Pour 15kg of sodium caseinate, 15kg of dipotassium hydrogen phosphate, and 4kg of sodium tripolyphosphate into a certain amount of ion-free water, stir at high speed, and after fully dissolved, pass through a colloid mill to make it uniform. become a paste.

[0040] (3) Mixing and shearing: First put 650kg (dry basis) of maltodextrin into the mixing tank, then put the paste liquid in step 2 and keep stirring, after a certain period of time, add the oil phase in step 1, Keep stirring to keep the temperature of the material liquid at 60-70°C, and then use high-speed shearing for 15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com