Novel high-temperature resistance insulation coating

An insulating coating and high-temperature-resistant technology, which is applied in the coating and other directions, can solve the problems of affecting the service life of the coating, increasing the cost, and deteriorating the mechanical properties of the coating, so as to achieve the effects of long service life, increased sealing, and improved electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

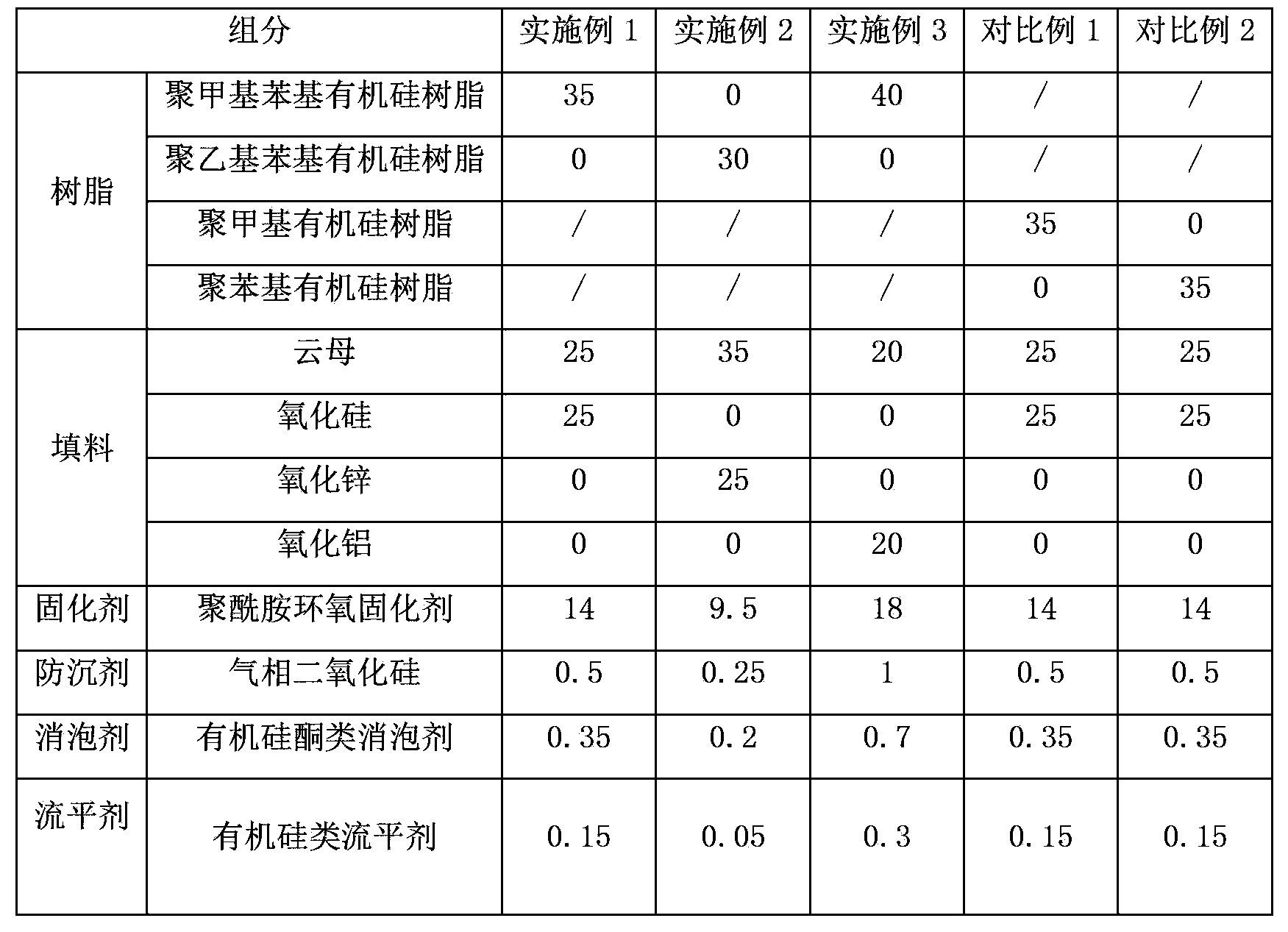

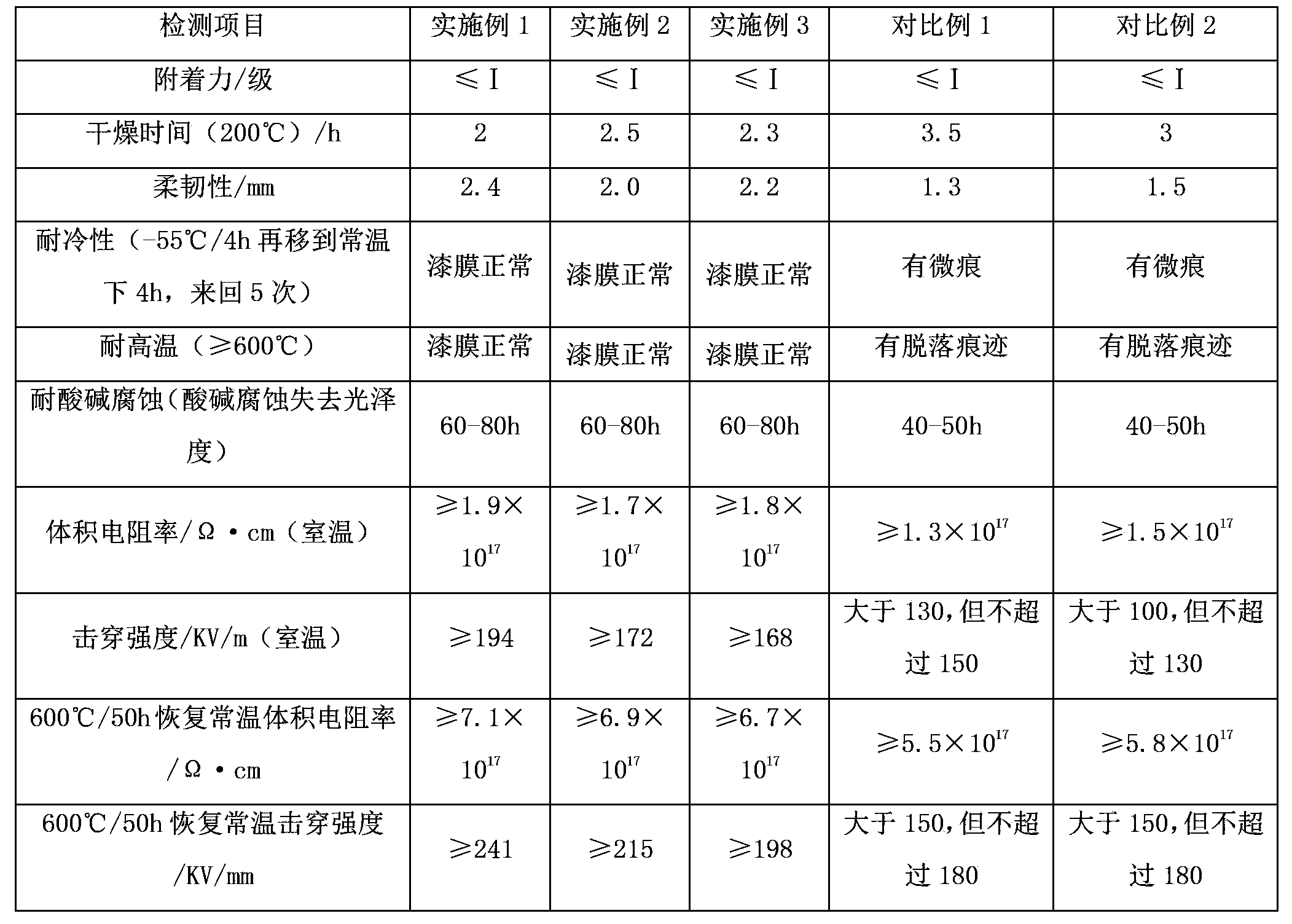

Embodiment 1

[0024] (1) Silicone pretreatment: Mix well with ammonia water and polymethylphenyl silicone resin, then place it for a certain period of time, wash it with distilled water until neutral, remove the water, and adjust the pressure to -0.1~-1.5Mpa in a vacuum state A small amount of residual water and ammonia can be removed under the pressure to obtain a silicone resin with less chlorine and better electrical properties.

[0025] (2) Coating preparation: Weigh the treated polymethylphenyl silicone resin obtained in step (2) according to the corresponding components in formula table 1, add filler first, mix well and then add auxiliary agent, and gradually dispersed in a sand mill until the fineness is below 20 μm to obtain the high temperature resistant insulating coating.

[0026] In this embodiment, polymethylphenyl silicone resin is generally made of CH 3 SiO 3 / 2 , (CH 3 ) 2 SiO 2 / 2 Copolymers composed of siloxane chains, and the introduction of phenyl siloxane chains in t...

Embodiment 2

[0028] (1) Silicone pretreatment: Mix well with ammonia water and polyethylphenyl silicone resin, then place it for a certain period of time, wash it with distilled water until neutral, remove the water, and adjust the pressure to -0.1~-1.5Mpa in a vacuum state A small amount of residual water and ammonia can be removed under the pressure to obtain a silicone resin with less chlorine and better electrical properties.

[0029] (2) Coating preparation: Weigh the treated polyethylphenyl silicone resin obtained in step (2) according to the corresponding components in formula table 1, add filler first, mix well and then add auxiliary agent, and gradually dispersed in a sand mill until the fineness is below 20 μm to obtain the high temperature resistant insulating coating.

[0030] In this example, the polyethylphenyl silicone resin is generally a copolymer containing ethyl and phenyl groups in the siloxane chain link. This copolymer has better elasticity than the product containing...

Embodiment 3

[0032] (1) Silicone pretreatment: Mix well with ammonia water and polymethylphenyl silicone resin, then place it for a certain period of time, wash it with distilled water until neutral, remove the water, and adjust the pressure to -0.1~-1.5Mpa in a vacuum state A small amount of residual water and ammonia can be removed under the pressure to obtain a silicone resin with less chlorine and better electrical properties.

[0033] (2) Coating preparation: Weigh the treated polymethylphenyl silicone resin obtained in step (2) according to the corresponding components in formula table 1, add filler first, mix well and then add auxiliary agent, and gradually dispersed in a sand mill until the fineness is below 20 μm to obtain the high temperature resistant insulating coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com