CdTe nanometer crystalline heterojunction solar battery and manufacturing method thereof

A solar cell and nanocrystalline technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficulty in ensuring device stability, unfavorable separation and transmission of carriers, and decline in efficiency of nanocrystalline cells. The effect of thinning, realizing mass production, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

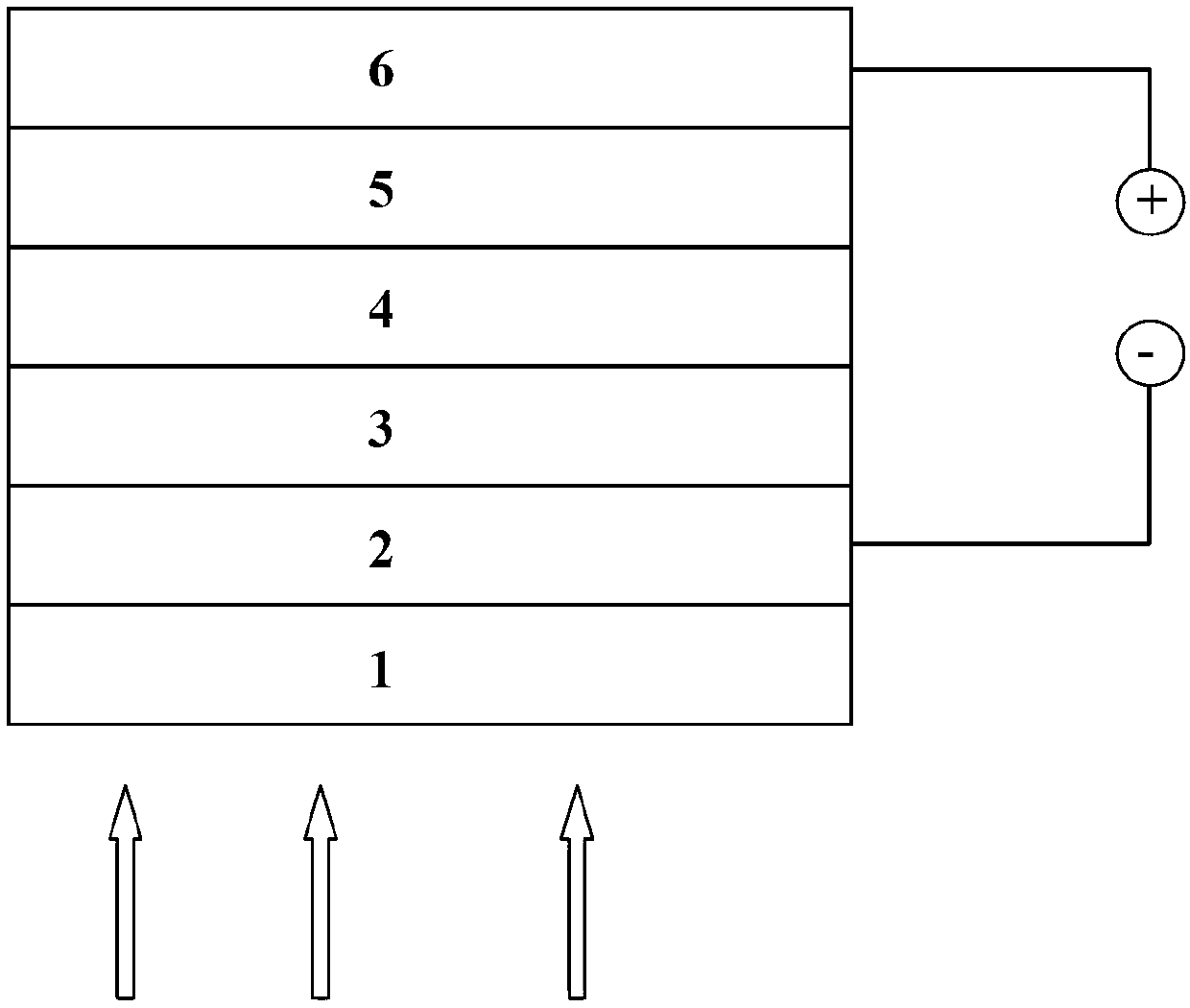

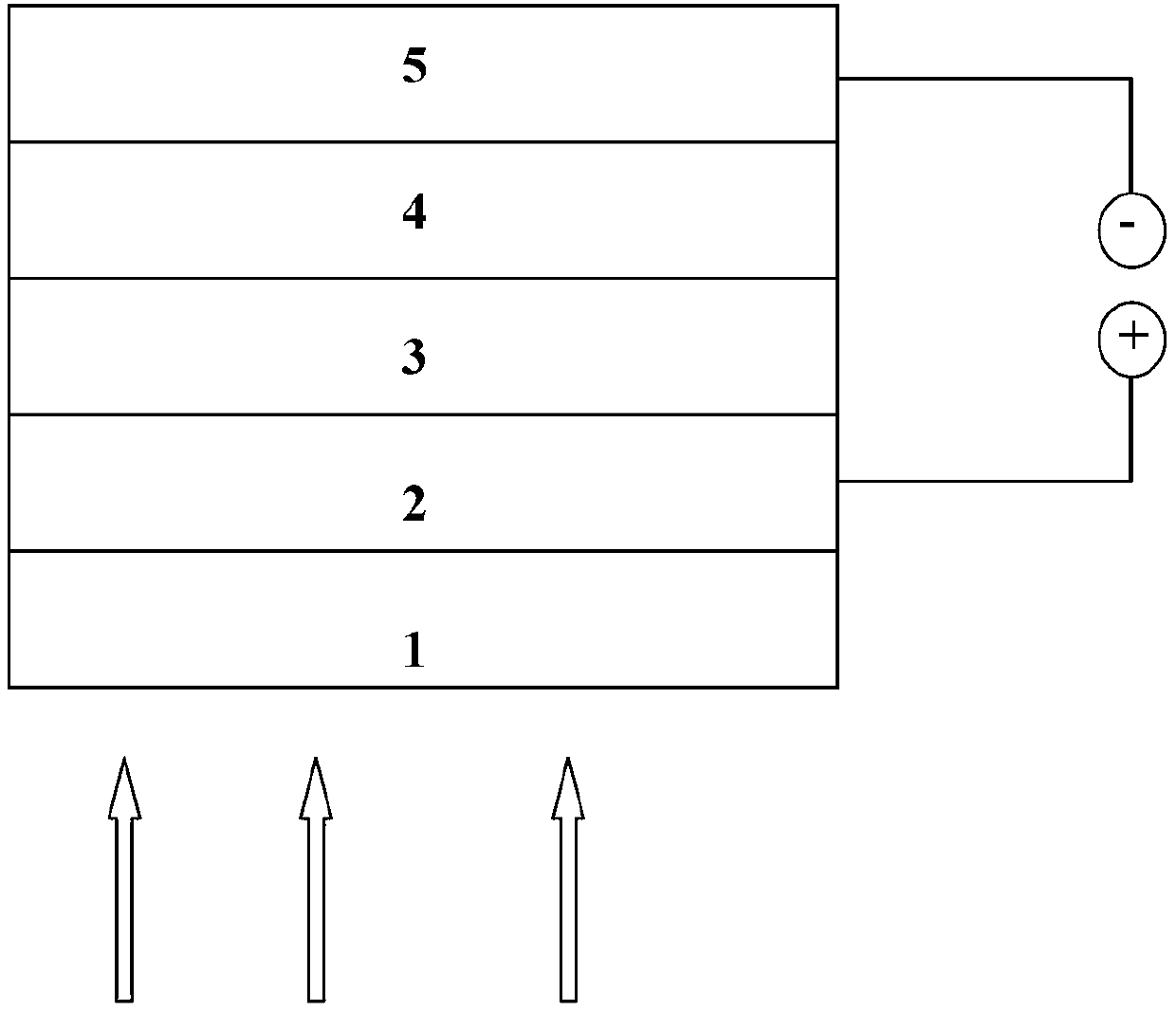

[0050] Example 1: Preparation of inverted structure CdTe nanocrystal / cadmium sulfide heterojunction solar cell

[0051] (1) Cleaning of ITO conductive glass substrate: (the specification is 15mm×15mm, the thickness of ITO is about 130nm, and its square resistance is about 20 ohms / square, purchased from Zhuhai Kaiwei Electronic Components Co., Ltd.) The sheet was ultrasonically treated in acetone, semiconductor special detergent, deionized water, and isopropanol for 10 minutes to clean the surface of the ITO substrate, and then the ITO sheet was placed in a constant temperature oven at 80°C for 4 hours to dry.

[0052] (2) Configure the ZnO precursor solution: dissolve zinc acetate dihydrate (0.5mol / L) and ethanolamine (0.5mol / L) in methoxyethanol (the above are analytically pure drugs, from Guangzhou Qianhui Chemical Glass Co., Ltd. Purchased by the company), reflux at 60°C for 2h, and filter through a 0.45μm filter to obtain a ZnO precursor solution.

[0053] (3) Preparation...

Embodiment 2

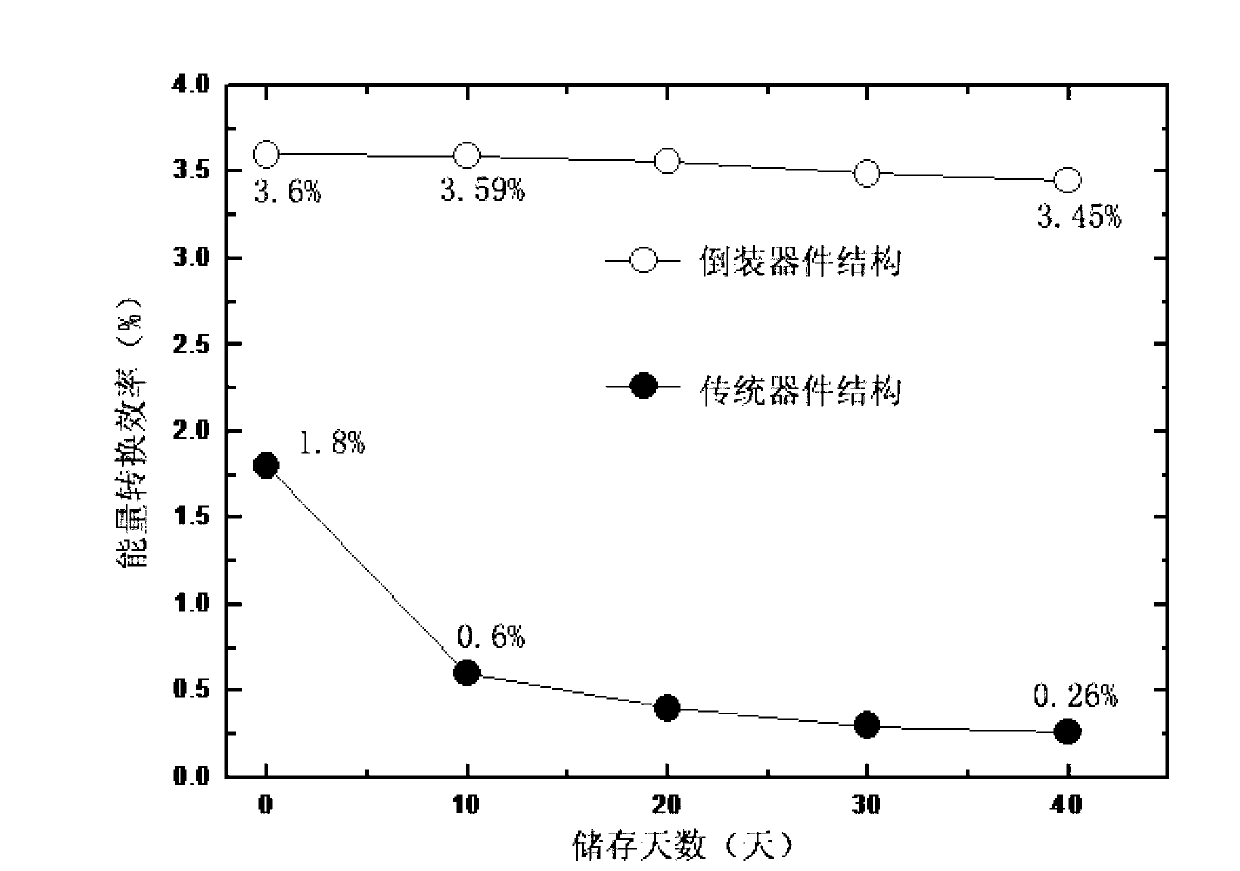

[0062] Example 2: Performance measurement of CdTe nanocrystalline heterojunction solar cells

[0063] Solar cells are energy conversion devices that convert solar energy into electrical energy, so the measurement of any performance parameters of solar cell devices must ultimately use sunlight as the test standard. The irradiance of AM1.5G measurement standard commonly used in laboratories is 1000W / m 2 . When using solar simulated light to test the performance of nanocrystalline solar cells, it is first necessary to use standard cells to determine whether the light source is combined with the irradiance of AM1.5G. Standard silicon solar cells are calibrated: under AM1.5G standard spectrum, that is, 1000W / m 2 Under the light irradiation of the irradiance, the obtained short-circuit current is 125mA. Once the irradiation intensity is determined, the device can be tested. The solar cell performance test is carried out with the sun simulated light, the energy conversion efficie...

Embodiment 3

[0074] Example 3: Effect of Nanocrystalline Dispersion Solvent on Device Performance

[0075] According to the preparation method of Example 1, prepare ITO / ZnO / CdS / CdTe / MoO 3 / Ag and ITO / CdS / CdTe / MoO 3 / Ag inverted structure device, in which the thickness of the CdTe active layer is 500nm, the solvents used are n-propanol, pyridine and pyridine / n-propanol mixed solvent (volume ratio is 1:1), the concentration of nanocrystals is uniform It was 40mg / mL, and other conditions were unchanged, and its performance was measured, and the results are shown in Table 3.

[0076] Table 3 Effect of nanocrystal dispersion solvent on device performance

[0077]

[0078] It can be seen from Table 3 that the performance of the device using n-propanol solvent is the worst, and the energy conversion efficiency is only 1.77%, while the performance of the device using pyridine reagent reaches 3%. When using the mixed solvent n-propanol / pyridine used in this case ( The volume ratio is 1:1), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com