Environment-friendly snow melting agent and preparation method thereof

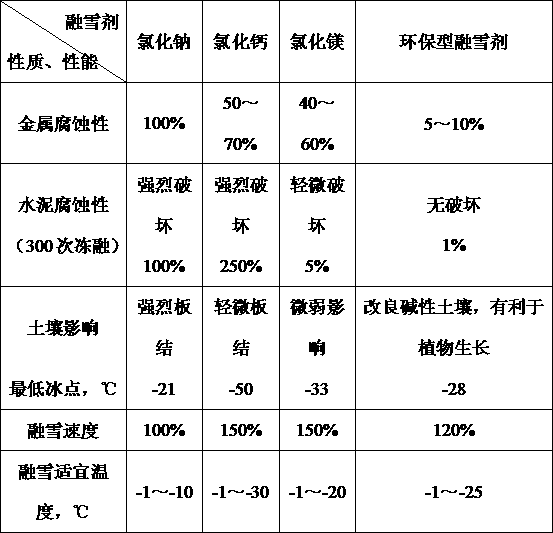

A snow-melting agent and an environmentally friendly technology, applied in the field of environmentally friendly snow-melting agent and its preparation, can solve the problems of small amount of application, high price, and long snow-melting reaction time, and achieve simple production process, low destructiveness, and good snow-melting and ice-melting performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] An environment-friendly deicing agent prepared by weight from the following raw materials: 30% calcium magnesium acetate, 15% potassium acetate, 20% calcium chloride, 25% magnesium chloride, 6.5% calcium oxide, and 3.5% corrosion inhibitor.

[0060] The corrosion inhibitor components are as follows by weight: 50% sodium hexametaphosphate, 25% sodium silicate, 10% zinc dihydrogen phosphate, 10% thiourea and 5% urea.

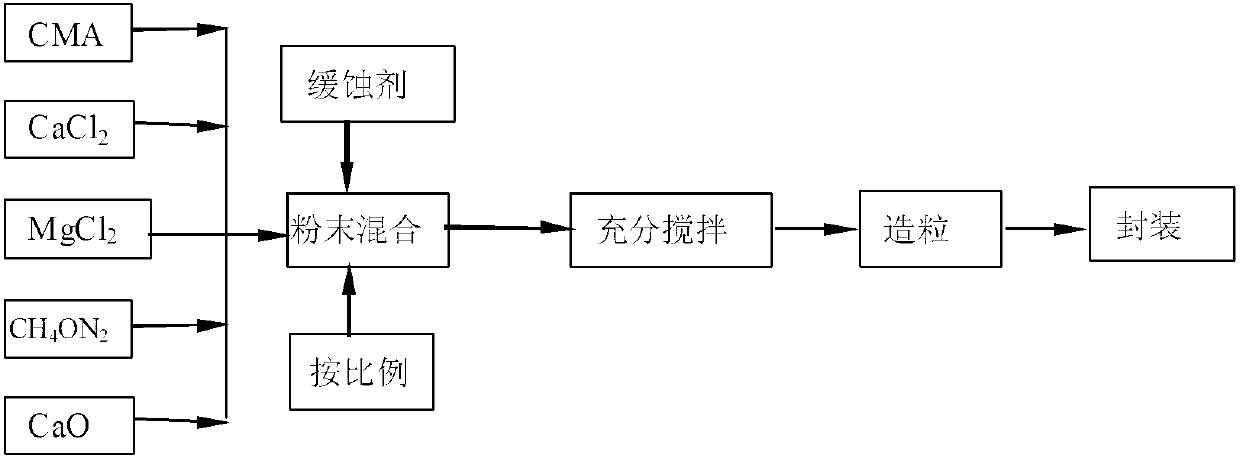

[0061] The preparation method of above-mentioned environment-friendly type deicing agent, the steps are as follows:

[0062] (1) Take the raw materials according to the above ratio, 30% calcium magnesium acetate, 15% potassium acetate, 20% calcium chloride, 25% magnesium chloride, 6.5% calcium oxide, 3.5% corrosion inhibitor, and grind them into powder with a ball mill ;

[0063] (2) Mix calcium magnesium acetate, potassium acetate, calcium chloride, magnesium chloride, and calcium oxide powder and then fully stir;

[0064] (3) After adding 3.5% slow-rele...

Embodiment 2

[0066] An environment-friendly deicing agent prepared by weight from the following raw materials: 35% calcium magnesium acetate, 15% potassium acetate, 20% calcium chloride, 20% magnesium chloride, 7.5% calcium oxide, and 2.5% corrosion inhibitor.

[0067] The corrosion inhibitor components are as follows by weight: 50% sodium hexametaphosphate, 25% sodium silicate, 10% zinc dihydrogen phosphate, 10% thiourea and 5% urea.

[0068] The preparation method of above-mentioned environment-friendly type deicing agent, the steps are as follows:

[0069] (1) Take the raw materials according to the above ratio, 35% of calcium magnesium acetate, 15% of potassium acetate, 20% of calcium chloride, 20% of magnesium chloride, 7.5% of calcium oxide, 2.5% of corrosion inhibitor, and grind them into powder with a ball mill ;

[0070] (2) Mix calcium magnesium acetate, potassium acetate, calcium chloride, magnesium chloride, and calcium oxide powder and then fully stir;

[0071] (3) After add...

Embodiment 3

[0073] An environment-friendly deicing agent prepared by weight from the following raw materials: 32% calcium magnesium acetate, 18% potassium acetate, 15% calcium chloride, 24% magnesium chloride, 8% calcium oxide and 3% corrosion inhibitor.

[0074] The corrosion inhibitor components are as follows by weight: 50% sodium hexametaphosphate, 25% sodium silicate, 10% zinc dihydrogen phosphate, 10% thiourea and 5% urea.

[0075] The preparation method of above-mentioned environment-friendly type deicing agent, the steps are as follows:

[0076] (1) Take the raw materials according to the above proportions, 32% of calcium magnesium acetate, 18% of potassium acetate, 15% of calcium chloride, 24% of magnesium chloride, 8% of calcium oxide, 3% of corrosion inhibitor, and grind them into powder with a ball mill ;

[0077] (2) Mix calcium magnesium acetate, potassium acetate, calcium chloride, magnesium chloride, and calcium oxide powder and then fully stir;

[0078] (3) After adding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com