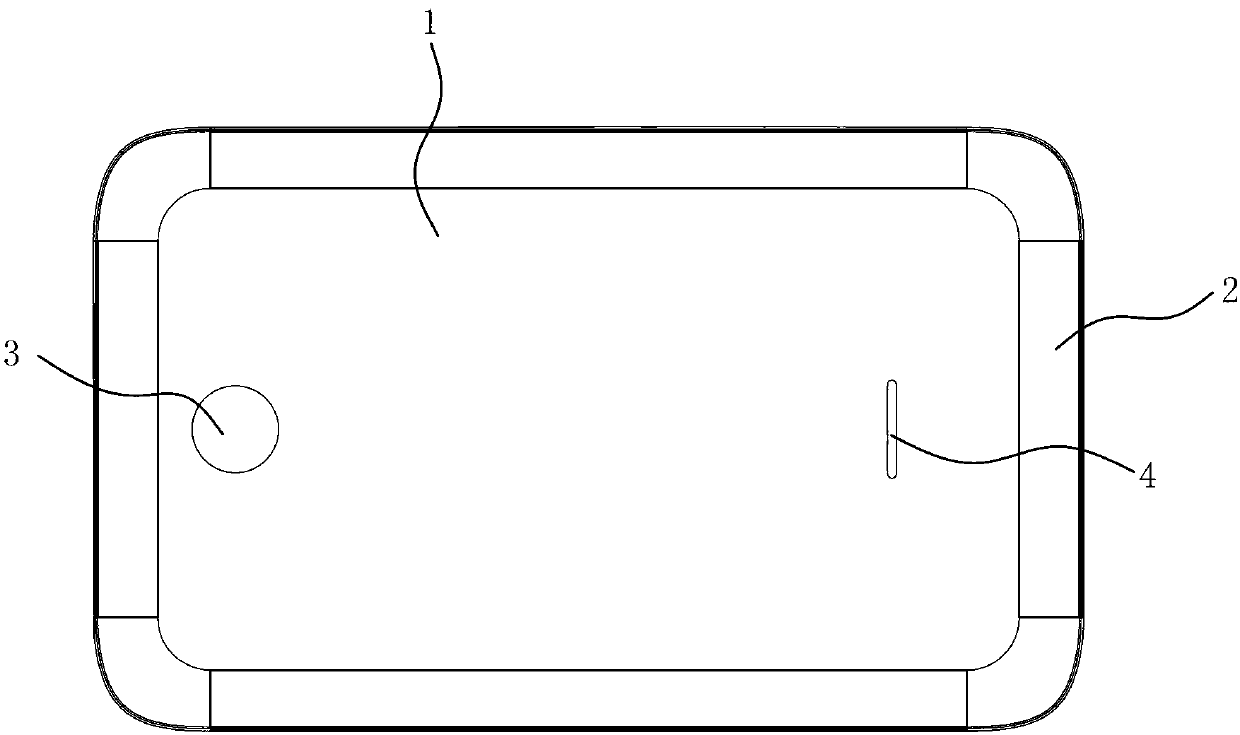

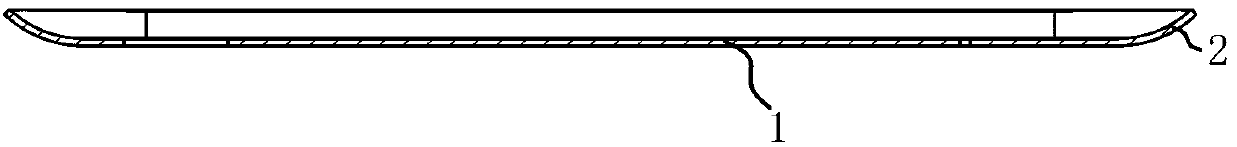

Three-dimensional (3D) glass machining method and cutting tool of numerical control machine

A processing method and cutting tool technology, applied in the field of machinery, can solve the problem that the cutting tool is not suitable for cutting 3D glass, etc., and achieve the effects of high yield, high qualification rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

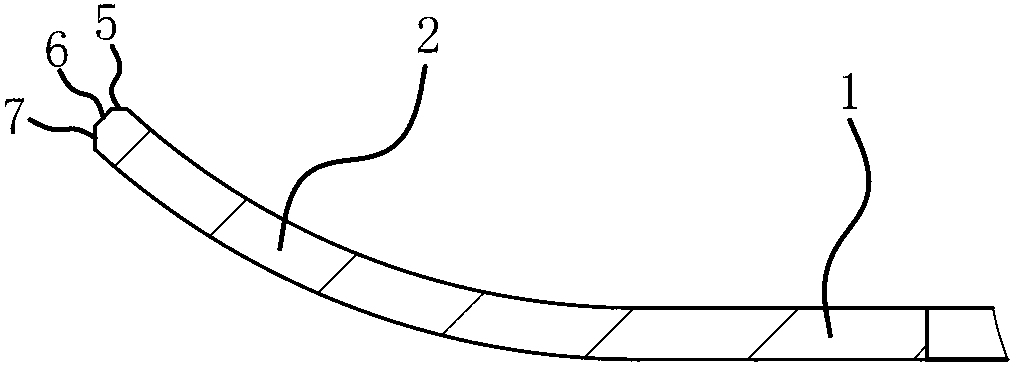

Embodiment 1

[0059] The edge margin between the 3D glass blank 8 and the finished 3D glass is 2.5㎜; the CNC machine tool is a special machine for grinding and processing Beijing Jingdiao glass; the rough cutting adopts the plan 1 processing; the diameter of the rough cutting tool head is 3㎜, and the emery is 93 The sand size is 350 mesh; the speed of the rough cutting tool is set to 50,000 rpm in the CNC machine tool processing program; the feed speed of the rough cutting tool along the cutting trajectory is 0.2 m / min; the margin after processing is 0.1 mm . The diameter of the cutter head of the fine cutting tool is 3mm, and the particle size of corundum 93 is 1000 mesh; the design cutting trajectory is a circle; the speed of the rough cutting tool is set to 50000 rpm in the CNC machine tool processing program; The feed speed along the cutting trajectory is 0.3 m / min. According to the above conditions, the finished product rate is above 99%, and the qualified rate of the finished product...

Embodiment 2

[0061] The edge margin between the 3D glass blank 8 and the finished 3D glass is 0.8㎜; the CNC machine tool is a special machine for grinding and processing Beijing Jingdiao glass; the rough cutting adopts the second processing method; the diameter of the rough cutting tool head is 6㎜, and the emery is 93 The grain size of the sand number is 400 mesh; the rotating speed of the rough cutting tool is set to be 50000 rpm in the CNC machine tool processing program; the feed speed of the rough cutting tool along the cutting track line is 0.3 m / min; the feed rate of the first circle is 0.5㎜, the feed rate of the second circle is 0.15㎜; the allowance after processing is 0.15㎜. The diameter of the cutter head of the fine cutting tool is 3 mm, and the particle size of the corundum 93 is 800 mesh; the speed of the rough cutting tool is set to 50,000 rpm in the CNC machine tool processing program; the design cutting trajectory is two circles; the first circle The feed rate is 0.1mm, and ...

Embodiment 3

[0063] The edge margin between the 3D glass blank 8 and the finished 3D glass is 0.2㎜; the CNC machine tool is Beijing Jingdiao glass grinding machine; the diameter of the cutting tool head is 5㎜, and the grain size of the corundum 93 is 1000 mesh; In the CNC machine tool processing program, the speed of the rough cutting tool is set to 30000 rpm; the design cutting trajectory is two circles; the feed rate of the first circle is 0.12㎜, and the feed rate of the second circle is 0.08㎜; the rough cutting tool The feed speed along the cutting trajectory is 0.2 m / min. According to the above conditions, the finished product rate is 100%, and the qualified rate of the finished product is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com