Efficient and low-cost preparing method for large-area graphical sapphire substrate

A patterned sapphire, low-cost technology, used in semiconductor devices, electrical components, circuits, etc., can solve problems such as slow exposure speed, limitations, and limitations of lithography technology, and achieve simple and easy process, low cost, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

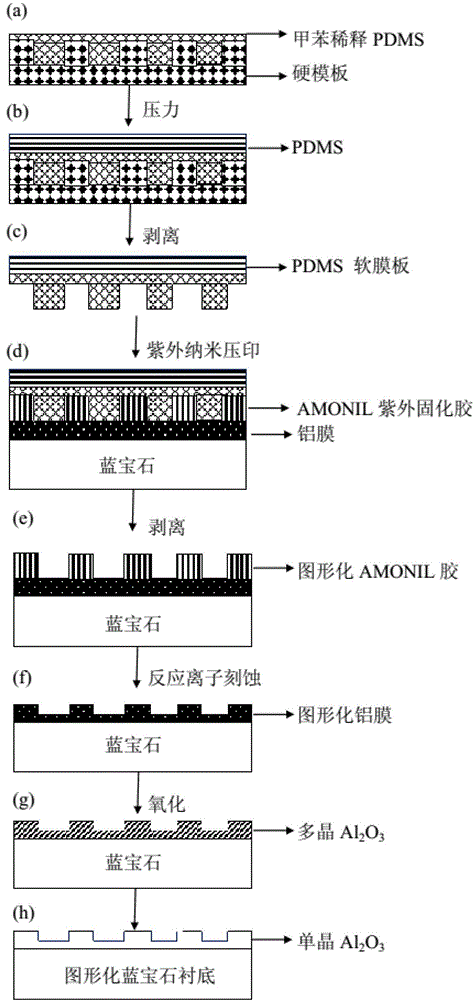

[0051] Prepare a patterned sapphire substrate for nitride epitaxial growth in the following order:

[0052] (1) Firstly, FDTS release agent is evaporated on the template of the grating structure pattern, and then the PDMS is diluted with toluene (toluene) at a concentration of 60%wt, stirred evenly, poured into a medical syringe, and then the diluted PDMS is injected into the grating structure pattern In the template, and cover the entire surface of the grating pattern structure template, and then spin the glue on the glue homogenizer: first, rotate the glue at a low speed of 900 rpm for 6 seconds, and then at a high speed of 3000 rpm, rotate the glue for 20 seconds.

[0053] (2) Prepare the PDMS prepolymer with PDMS prepolymer: curing agent = 1:10, stir evenly, and coat it on PDMS with a mass fraction of 60%wt, and then press the PDMS plate of 80μm to 120μm on the PDMS On the prepolymer, place the template on a hot plate, set the temperature of the hot plate to 90°C, cure for...

Embodiment 2

[0062] Prepare a patterned sapphire substrate for nitride epitaxial growth in the following order:

[0063] (1) Firstly, FDTS release agent is evaporated on the template of the grating structure pattern, and then PDMS is diluted with toluene, the mass concentration is 60%wt, stirred evenly, poured into a medical syringe, and then the diluted PDMS is injected into the template of the grating structure pattern and cover the entire surface of the grating graphic structure template, and then spin the glue on the glue spreader: at a low speed of 900 rpm, rotate the glue for 6 seconds, and at a high speed of 3000 rpm, rotate the glue for 20 seconds.

[0064] (2) Prepare the PDMS prepolymer with PDMS prepolymer: curing agent = 1:10, stir evenly, and coat it on 60%wt PDMS, then press the thick elastic PDMS plate on the PDMS prepolymer, Place the template on a hot plate, set the temperature of the hot plate to 90°C, solidify for 2-3 h, and cool naturally.

[0065] (3) Use tweezers to ...

Embodiment 3

[0073] Crystal Structure Testing

[0074] The crystal structure of the prepared patterned sapphire substrate was tested by high-resolution X-ray diffractometer. Image 6 is the scan result of the patterned sapphire substrate (11-23), Figure 7 It is the XRD-ω / 2θ scanning result of the patterned sapphire substrate (0006), and the result shows that the diffraction peak width at half maximum of the patterned sapphire substrate (0006) is FWHM=0.0101°. Figure 8 It is the XRD-ω / 2θ scanning result of the unpatterned sapphire substrate (0006), and the result shows that the half maximum width of the diffraction peak of the unpatterned sapphire substrate (0006) is FWHM=0.0133°. Image 6 The XRD-Φ scanning result of the patterned sapphire substrate (11-23), the crystal plane angle between (11-23) and (0006) is φ=61.2°, and the sample is scanned from 0 to 360° around the surface normal n . exist Image 6 There are 6 diffraction peaks at equal intervals, and the difference between a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com