BCD semiconductor device and manufacturing method thereof

A technology of semiconductors and devices, which is applied in the field of semiconductor power devices, can solve problems such as limitations and rise in on-resistance, achieve high withstand voltage, reduce specific on-resistance, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

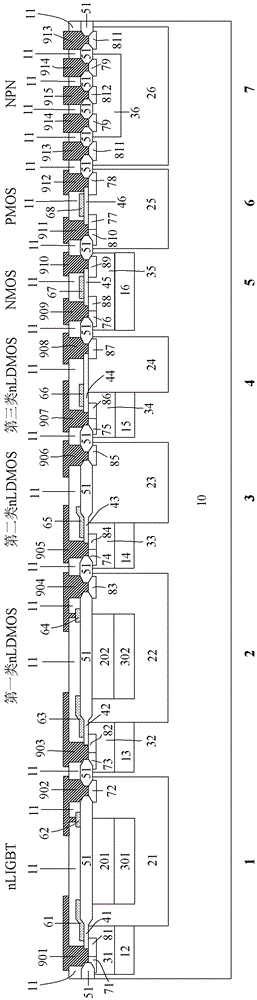

[0031] The invention provides a novel BCD semiconductor device, such as figure 1 Shown:

[0032] The high-voltage nLIGBT device 1 is directly built in the p-type substrate 10, the n-type heavily doped layer 201 is located under the field oxide layer 51 and surrounded by the n-type drift region well 21; the p-type drop field layer 301 is located on the n-type heavily doped Below the miscellaneous layer 201; p + The anode region 72 is under the anode metal 902 and surrounded by the n-type drift region well 21; n + Cathode region 81 and p + The well contact region 71 is located side by side under the cathode metal 901 and surrounded by the p-type body region 31; the polysilicon gate 61 is partly on the gate oxide layer 41 and partly on the field oxide layer 51; between the cathode metal 901, the anode metal 902 and the polysilicon gate 61 are isolated from each other by a pre-metal dielectric 11.

[0033] The first type of high-voltage nLDMOS device 2 is directly made in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com