Method for preparing sponge titanium on special resistance furnace by molten salt electrolysis method

A special resistance and molten salt electrolysis technology, applied in the field of smelting, can solve the problems of poor corrosion resistance of high temperature molten salt, poor vacuum sealing, high energy consumption of resistance furnaces, etc., and achieve the effects of high sealing, convenient operation and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

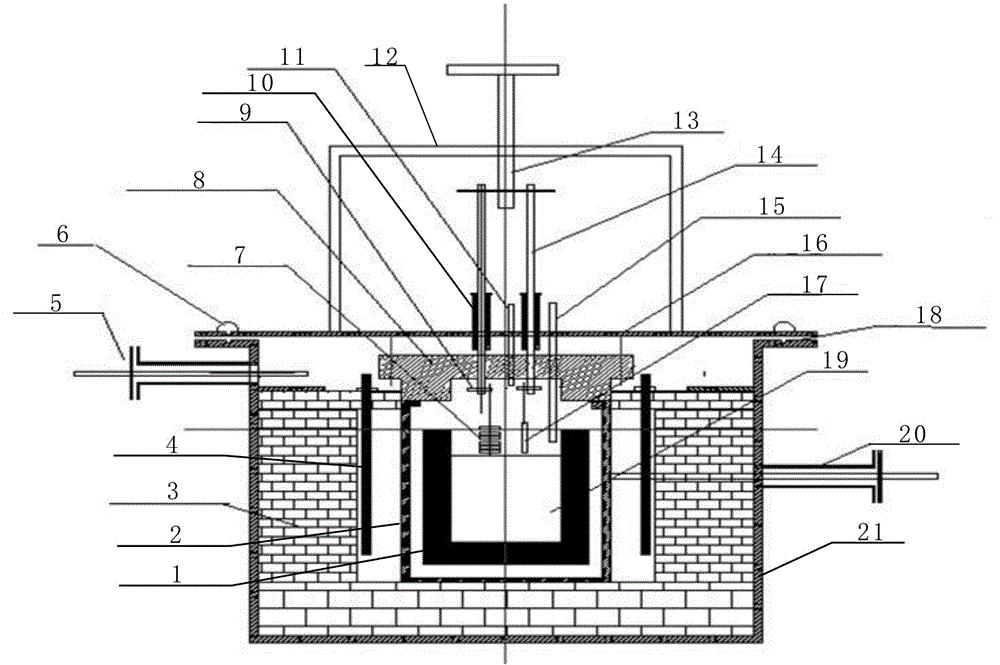

[0025] The invention is a method for preparing titanium sponge by molten salt electrolysis on a special resistance furnace, and is also one of the extension methods of molten salt electrolysis in the molten salt electrolysis method. In this method, a vacuum reactor is embedded in a special resistance furnace and matched with The set refractory cover is used to seal the vacuum reactor, and the matching furnace cover is used to seal the special resistance furnace. The thermal efficiency of the special resistance furnace can be fully utilized, and the sponge titanium with better quality can be electrolyzed, making the FFC molten salt electrolysis method The development technology is more mature, safe and energy-saving.

[0026] The special resistance furnace 3 is equipped with a conductive device 5 and a temperature measuring device 20. The conductive device 5 makes the maximum temperature of the special resistance furnace 3 not lower than 950°C. The molten salt electrolysis metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com