Multifunctional efficient tube type heating device

A tubular heating and multi-functional technology, applied in electric furnace heating, furnace control device, heating chamber maintenance, etc., can solve problems such as equipment circuit current overload, difficulty in controlling the heating atmosphere of tube furnace, and small cooling rate of tube furnace , to improve the heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the drawings and embodiments.

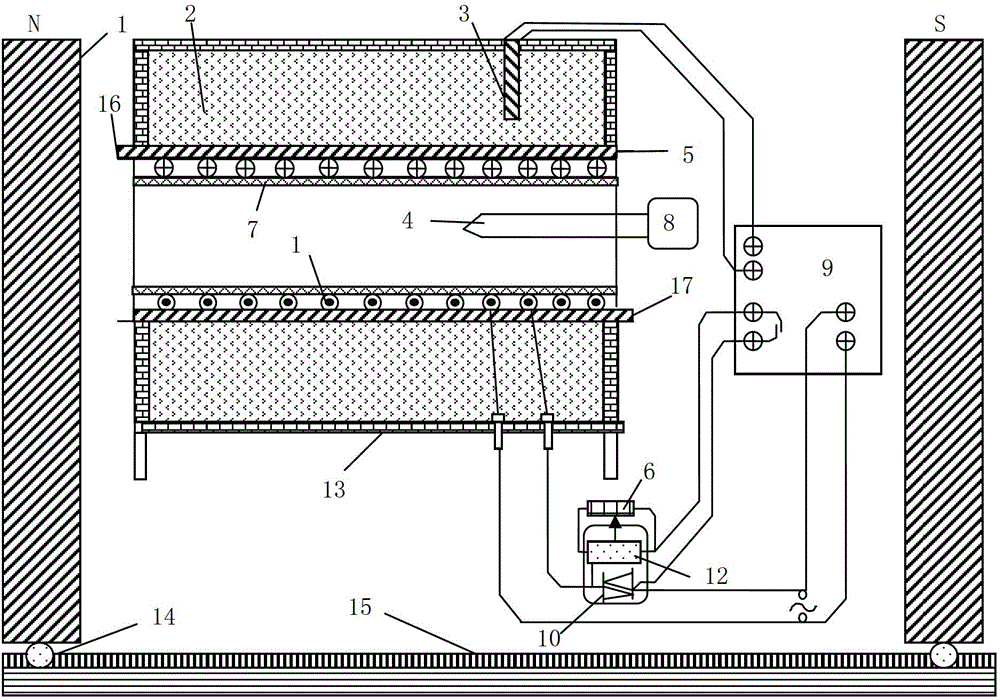

[0028] Such as figure 1 As shown, the multifunctional tubular furnace consists of an adjustable magnetic field 1, a refractory fiber insulation layer 2, a temperature control thermocouple 3, a temperature measuring thermocouple 4, a condenser tube 5, a manual voltage regulator 6, a furnace 7, and a digital display temperature test Instrument 8, temperature numerical control intelligent instrument 9, thyristor 10, electric furnace wire 11, trigger circuit 12, furnace wall 13, pulley 14, slide rail 15, water inlet 16, water outlet 17.

[0029] Wherein the entire heating system is placed between the N pole and the S pole of the adjustable magnetic field 1. The adjustable magnetic field 1 is composed of two movable permanent magnets, and a pulley 14 is installed at the bottom of both, and the pulley can be mounted on the slide rail 15. Free movement, adjust the directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com