Self-aligning metal oxide thin film transistor and manufacturing method thereof

A technology of oxide film and production method, which is applied in transistor, semiconductor/solid-state device manufacturing, electrical components and other directions, can solve the problems of self-aligned structure stability, production efficiency and cost, production line compatibility, etc. Improved on-state current and mobility, low cost, reduced overlap capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A specific example of the manufacturing method of the thin film transistor of the present invention is as follows Figure 1 to Figure 7 shown, including the following steps:

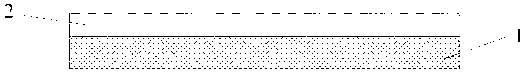

[0070] Such as figure 1 As shown, the substrate 1 used is a glass substrate, and a 60nm metal oxide semiconductor indium gallium zinc oxide (IGZO) thin film 2 is grown on the substrate by magnetron sputtering.

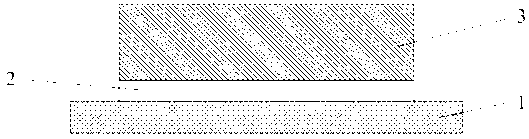

[0071] Such as figure 2 As shown, the photoresist 3 is spin-coated, and the indium gallium zinc oxide thin film 2 is photolithographically etched; the photoresist 3 is removed by ultrasonication with acetone.

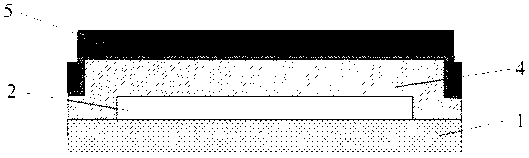

[0072] Such as image 3 As shown, a 200nm silicon oxide film 4 is deposited on the patterned indium gallium zinc oxide film 2 by plasma enhanced chemical vapor deposition (PECVD); then a 150nm silicon oxide film is grown by magnetron sputtering Metal molybdenum film 5.

[0073] Such as Figure 4 As shown, the photoresist 6 is spin-coated, the molybdenum electrode and the sil...

Embodiment 2

[0078] Another specific example of the manufacturing method of the thin film transistor of the present invention is as follows Figure 8 to Figure 15 shown, including the following steps:

[0079] Such as Figure 8 As shown, the substrate 1 used is a glass substrate, and a layer of 80nm metal oxide semiconductor indium gallium zinc oxide (IGZO) thin film 2 is grown on the substrate by magnetron sputtering.

[0080] Such as Figure 9 As shown, the photoresist 3 is spin-coated, and the indium gallium zinc oxide thin film 2 is photolithographically etched; the photoresist 3 is removed by ultrasonication with acetone.

[0081] Such as Figure 10As shown, a layer of 300nm silicon oxide film 4 is deposited on the patterned indium gallium zinc oxide film 2 by plasma enhanced chemical vapor deposition (PECVD); then a layer of 300nm silicon oxide film is grown by magnetron sputtering Metal molybdenum film 5.

[0082] Such as Figure 11 As shown, the photoresist 6 is spin-coated, ...

Embodiment 3

[0088] Another specific example of the manufacturing method of the thin film transistor of the present invention is as follows Figure 16 to Figure 22 shown, including the following steps:

[0089] Such as Figure 16 As shown, the substrate 1 used is a flexible substrate, and a layer of 40nm high-resistivity metal oxide semiconductor indium gallium zinc oxide (IGZO) film 2 is grown on the substrate by magnetron sputtering; and then grown by magnetron sputtering A 5nm low-resistivity indium tin oxide film (ITO) 17 .

[0090] Such as Figure 17 As shown, the photoresist 3 is spin-coated, the indium gallium zinc oxide thin film 2 and the indium tin oxide thin film 17 are photolithographically and etched; the photoresist 3 is removed by ultrasonication with acetone.

[0091] Such as Figure 18 As shown, a 100nm aluminum oxide film 4 is deposited on the patterned indium tin oxide film 17 by atomic layer deposition (ALD); then a 50nm metal molybdenum film 5 is grown by magnetron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com