Bi-component adhesive composition and preparation method thereof

A two-component adhesive and composition technology, used in adhesives, adhesive additives, carboxyl rubber adhesives, etc., can solve the problem of poor heat resistance and water resistance, inability to use impact resistance, low bonding strength problems, to achieve the effect of reducing water absorption, improving heat resistance, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

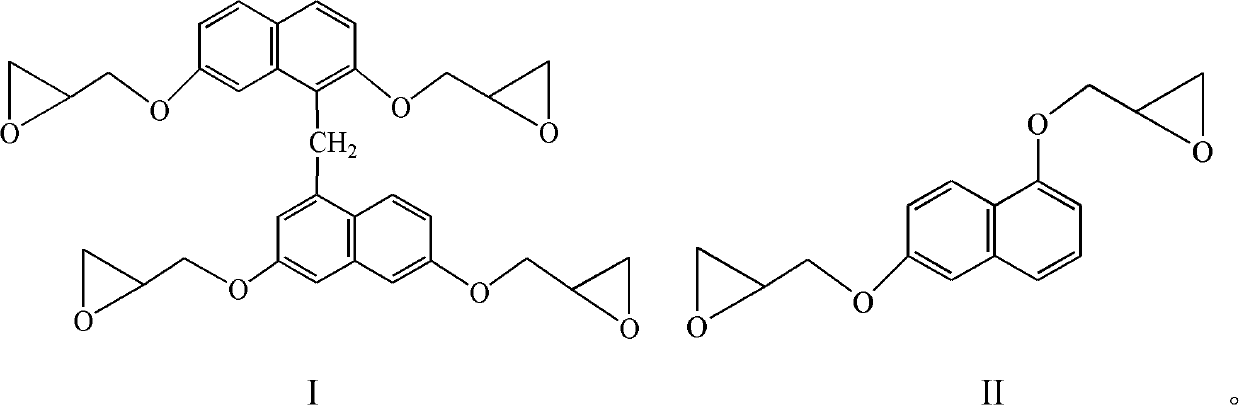

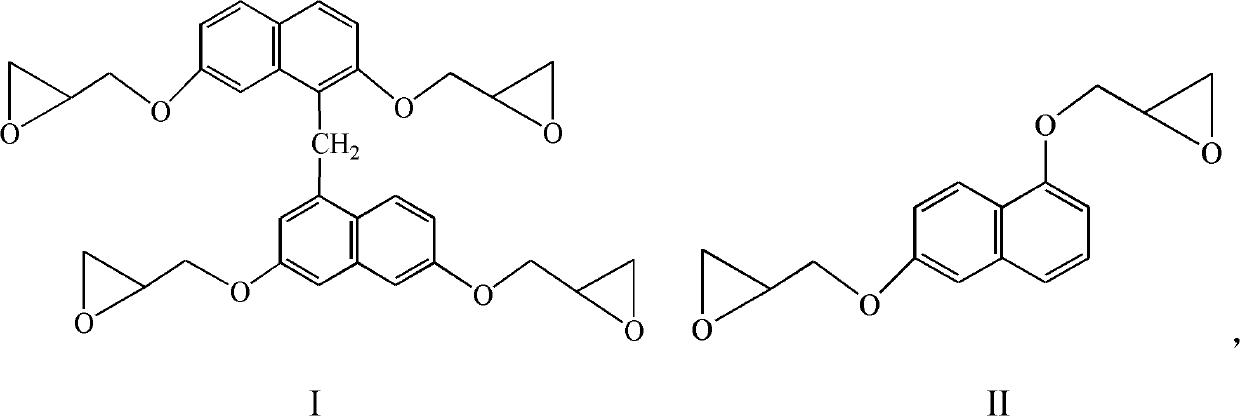

[0028] Preferably, in the present invention, the epoxy equivalent of the third epoxy resin is 120-250 g / eq, and the content of naphthalene ring groups is 40-60 wt%. As an embodiment of the present invention, the third epoxy resin may be an epoxy resin represented by formula I or formula II, but is not limited thereto.

[0029]

[0030] In the present invention, the third epoxy resin can directly use a commercially available product, for example, it can be selected from HP-4700 of DIC Corporation of Japan.

[0031] In the present invention, the toughening agent is properly selected so that the two-component adhesive of the present invention has good toughness and impact resistance within the service temperature of the automobile without reducing heat resistance and rigidity, and at the same time It has good low-temperature flexibility and adhesion, so that the two-component adhesive of the present invention meets the use requirements at -40°C-80°C. Specifically, the first t...

Embodiment 1-3

[0052] (1) According to the raw material ratio shown in Table 1, mix the first epoxy resin, the second epoxy resin, the third epoxy resin and the first toughening agent evenly at 65°C, and then add filler and thixotropic The mixture was mixed to a powder-free state, rolled into a paste on a three-roll mill, and vacuum degassed for 30 minutes to obtain component A of the two-component adhesives S1-S3 of Examples 1-3.

[0053] (2) According to the ratio of raw materials shown in Table 1, the second toughening agent, normal temperature curing agent, high temperature curing agent and accelerator are stirred and mixed evenly at room temperature to a powder-free state, and then rolled on a three-roll mill Paste, after vacuum degassing for 30 minutes, the B components of the two-component adhesives S1-S3 of Examples 1-3 were obtained.

[0054] Table 1

[0055]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com